Caspeter Homogeneous Mushroom Powder from Zhongke: Empowered by Technology, Freshness and Aroma Upgraded!

Introduction

In the trend of pursuing healthy and delicious diets, mushroom powder, with its natural flavor enhancement and rich nutrition, has become an essential condiment in the kitchen. However, the crude production process and limited flavor of traditional mushroom powder have always left diners who pursue the ultimate feeling regretful. Today, Caspeter Homogeneous Mushroom Powder from Zhongke redefines the standards of mushroom powder with the power of technology, bringing you an unprecedented fresh and fragrant experience!

I. Product Features and Technical Advantages:

Empowered by technology, nutrition is fully released

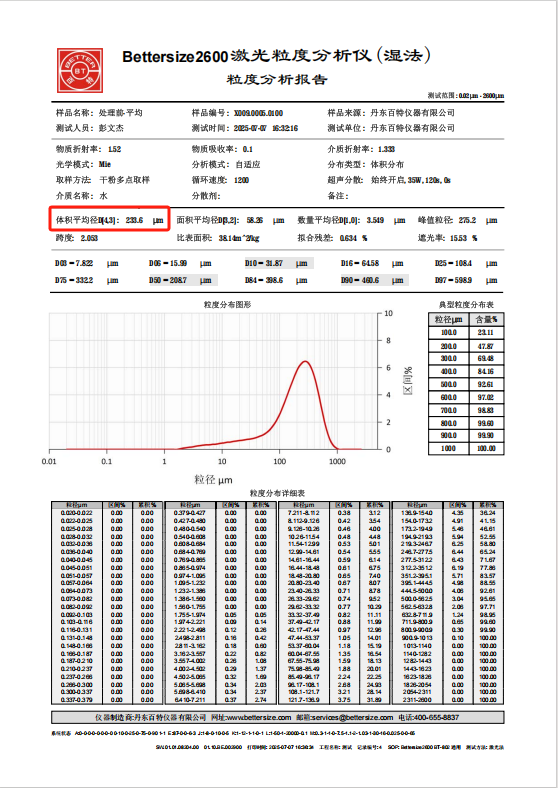

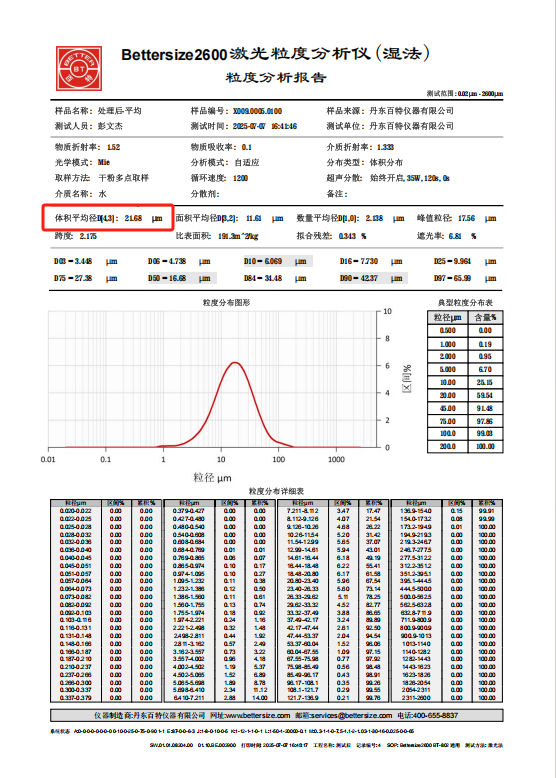

Caspeter homogenized mushroom powder from Zhongke adopts advanced extrusion spray technology. Through the effects of high temperature, high pressure and high shear force, it thoroughly destroys the cell walls of mushrooms and releases more nutrients. Lentinan, protein, amino acids (including seven essential amino acids), polyphenols, and various minerals and vitamins are fully retained during homogenization treatment, safeguarding your health.

Ii. Experimental Methods

1. Process flow

Fresh shiitake mushrooms → Washing → Cutting into pieces → pulping → homogenization treatment → extrusion spray drying → finished product inspection

2. The high-pressure homogenizer achieves fine processing of materials through triple actions:

High-pressure pump pressurization: The material is pressurized to 1200bar (or even higher), forming a high-speed flowing liquid flow. The function of the homogenizing valve: The material is forced to pass through the narrow gap of the homogenizing valve. The sudden drop in pressure causes cavitation effect (the liquid vaporizes to form micro-bubbles and then bursts), while generating high-speed shear force and impact force. Particle fragmentation and dispersion: The three effects work in synergy to thoroughly break down the cell walls of shiitake mushrooms, releasing intracellular components (such as polysaccharides and proteins) and forming a uniform and fine powder.

Iii. Conclusion

Food processing: Replacing traditional grinding techniques, it significantly enhances the freshness, aroma and nutritional value of mushroom powder, and is suitable for condiments, vegetarian products, etc. Optimize the homogenization effect of liquid foods such as dairy products and fruit juices to prevent stratification and sedimentation.

Functional additives: After high-pressure homogenization, lentinan is more easily absorbed by the human body and can be used in health products or functional foods.

Industrial efficiency: Continuous production, large processing capacity, and easy to clean and maintain (such as ethanol storage to prevent metal corrosion).

Post time: Jul-26-2025