I. Breakthrough! The new nano-process for vitamin E —–reduces particle size by 80% and doubles bioavailability

Innovation point

1.1200bar high-pressure instantaneous crushing of oil droplets

2. The dosage of surfactant is reduced by 50%

3.The activity is retained by a low-temperature process at 3.10℃

4.30-day storage stability meets the standard

Ii. Experimental Records for the Preparation of Vitamin E nano-dispersions

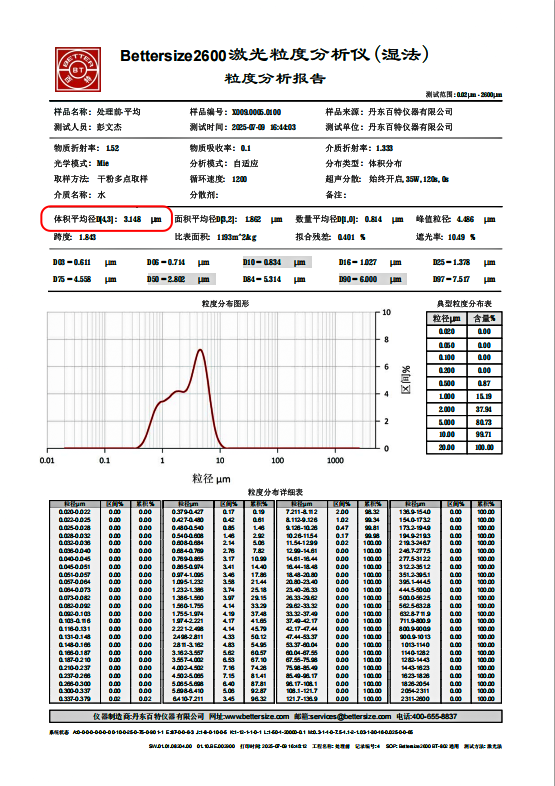

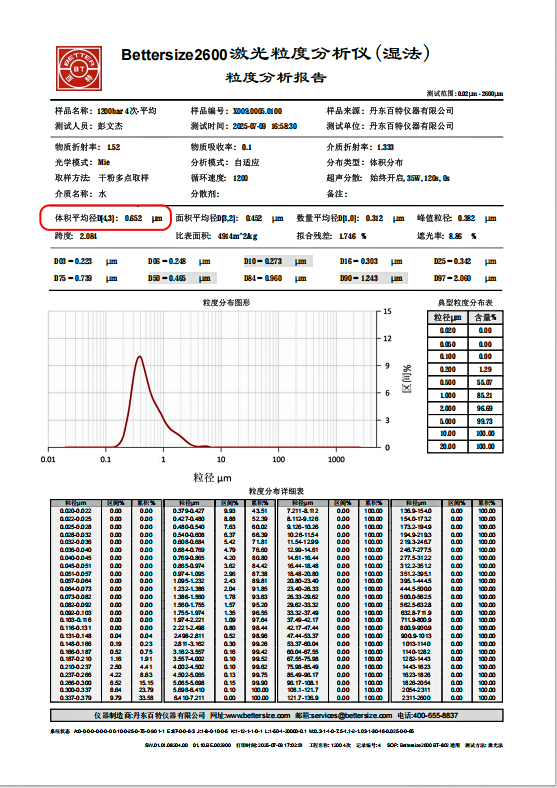

1.Optimization of the preparation process for vitamin E nano-dispersion

<1> Experiment Date: July 15, 2025

<2> Experimental objective: To establish the optimal process parameters for the preparation of vitamin E nanodispersions by Peter high-pressure homogenizer (PT-10)

2. Experimental materials

<1> raw materials: vitamin E oil (purity ≥98%)

<2> Carrier: Medium-chain triglycerides (MCT oil)

<3> Emulsifier: Tween 80 (3% dosage)

<4>Youdaoplaceholder0 Equipment: Peter high-pressure homogenizer (working pressure 0-1200bar)

3. Process flow

Preparation of premixes:

<1> Vitamin E oil and MCT oil are mixed in a ratio of 1:4

<2>Add Tween and stir in a water bath at 80 or 60℃ for 30 minutes until completely dissolved

4. Primary emulsification

<1> High shear homogenizer at 10,000 RPM for 5 minutes

<2> Form a crude emulsion (particle size ≈5μm)

5. High-pressure homogenization treatment

<1>Pre-cool the equipment to 15℃

<2>The discharge temperature should be controlled at 10℃

<3> Parameter Settings: 1200bar ×45 cycles

<4> Flow control: 10L/H

6. Stability test

<1>Centrifuge at 4000rpm for 30 minutes and observe the stratification

<2>Long-term storage: Monitor particle size changes for 30 days at 4 ° C /25 ° C

7.Core data

8. Key Findings

<1>Nanosizing is achieved through four cycles at a pressure of 1200bar

<2>The bioavailability was increased by 217% compared with the untreated sample

<3>The particle size growth is less than 10% after being stored at 4℃ for 30 days

<4>There is no visible stratification to the naked eye after centrifugation

9. Technological advantages

<1>Avoid the use of organic solvents and comply with green production

<2>The particle size controllability reaches ±1nm accuracy

<3>The batch reproducibility CV value is less than 5%

<4>The equipment cleaning cycle has been shortened to 10 minutes

10. Application value

<1>Functional food additives

<2>Health care product nano delivery system

<3>Enhanced transdermal absorption of cosmetics

<4>Development of sustained-release drug carriers

Post time: Jul-17-2025