In many industries, getting a consistent, uniform product is pretty important. That's where the Valve Homogenizer really comes into play. It’s a pretty nifty device that helps break down particles and make mixtures more uniform. Companies like Homogenizer Services rely on this tech to help boost their product quality.

Basically, what it does is push the mixture through a tiny valve at really high pressure, which effectively crushes the particles apart. You’ll find this kind of setup often in food production, pharmaceuticals, and cosmetics. But here’s the thing— not all mixtures respond the same way. Some might need a few tweaks to get everything just right.

Even though the technology is pretty solid, it’s not without its challenges. Operators need to keep a close eye on the consistency—things can change because of different raw materials, for instance. So, regular recalibration is kind of a must if you want the best results. The Valve Homogenizer is powerful stuff, but you’ve gotta use it thoughtfully and keep checking on how everything’s going to make sure you get the desired outcome.

A valve homogenizer is essential in various processing industries. It breaks down particles to achieve better consistency in products. The device uses pressure to force a mixture through a valve. This action reduces the size of particles and creates a uniform texture. It is crucial for products like emulsions and suspensions. The dispersal of particles occurs rapidly. This process enhances the appearance and stability of the product.

Using a valve homogenizer can be tricky. Operators must monitor pressure closely. High pressure may lead to wear. This can affect efficiency over time. Regular maintenance is vital to avoid down-time. Proper care helps extend the homogenizer's lifespan.

Tips: Check the pressure settings frequently. This ensures optimal performance. Understanding your mixture helps adjust the valve correctly. Experiment with different settings for best results. Keep records of the process to track any inconsistencies.

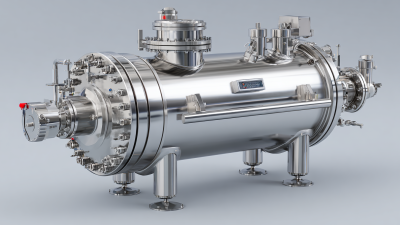

A valve homogenizer relies on several key components to achieve effective homogenization in various applications. The primary part is the homogenizing valve. This is where the magic happens. The product is forced through a narrow gap, creating intense pressure and shear forces. These forces reduce particle size and create a uniform mixture.

Another essential component is the pressure pump. It generates the necessary pressure to push the fluid through the homogenizing valve. Without adequate pressure, the homogenization process may not be effective. Adjusting pressure settings can influence the final product quality, requiring constant monitoring and adjustments.

Additionally, many homogenizers have a recirculation loop. This setup allows for multiple passes through the valve. Each pass enhances the uniformity of the mixture. However, it can be tricky. Too many passes can lead to overheating or excessive shear. Operators need to find the right balance for optimal results.

A valve homogenizer is a crucial piece of equipment in many industries. It primarily functions to reduce particle size and improve consistency in mixtures. The homogenization process can make a significant difference in product quality.

During operation, the mixture is forced through a valve at high pressure. This process creates shear forces that break down particles effectively. The result is a uniform blend of materials, whether it's for food, pharmaceuticals, or cosmetic products. Interestingly, not all mixtures achieve the same results. Variables like pressure and temperature can alter the effectiveness of the homogenization. It's essential to monitor these factors closely.

Achieving the perfect blend isn't always straightforward. Sometimes, the particle size might not be reduced as expected. This could be due to a number of factors, including equipment limitations or incorrect settings. Operators must pay close attention and adjust settings as needed. The homogenization process reveals the complexity involved in achieving uniformity and the need for ongoing adjustments. Understanding these intricacies can lead to improved products and better outcomes.

Valve homogenizers play a crucial role in various industries. They find applications in food processing, pharmaceuticals, and cosmetics. In the food industry, these machines create smooth textures in products like sauces and dairy. They help break down fat globules, ensuring a consistent product. Without proper homogenization, the quality can suffer, leading to separation and undesirable textures.

In pharmaceuticals, valve homogenizers ensure uniformity in emulsions and suspensions. This is vital for the efficacy of medicines. A poorly homogenized product can lead to variations in drug delivery, impacting patient safety. Precision is often hard to achieve, leaving room for errors.

Cosmetic manufacturers also rely on valve homogenizers for their creams and lotions. These products require stable emulsions for effectiveness. Clumping or inconsistency can lead to consumer dissatisfaction. Achieving the perfect blend is often a challenge, but it's essential for success. Each industry must carefully monitor the homogenization process to ensure quality and performance meet standards.

Valve homogenizers play a crucial role in food and beverage production. They work by forcing products through small openings, which creates high pressure. This process reduces particle size and improves texture. When used correctly, valve homogenizers can enhance flavor and stability.

Using valve homogenizers has several benefits. One of the key advantages is uniformity. Homogenized products have a consistent texture, which appeals to consumers. This consistency can lead to increased customer satisfaction. Additionally, valve homogenizers help improve the shelf life of products. By breaking down particles, they reduce the potential for separation.

**Tip:** Regular maintenance of the homogenizer is essential. Neglecting it can lead to uneven results.

Another benefit is improved flavor release. Smaller particles can enhance the taste experience. Products like sauces or dairy benefit greatly from this. However, achieving the right parameters can be tricky. Each recipe may require adjustments.

**Tip:** Always experiment with pressure settings. The right pressure can transform the final product.

Valve homogenizers also aid in emulsification. This is critical in products like dressings. Without proper emulsification, ingredients can separate. Yet, finding the optimal balance can be challenging. Over-homogenization can negatively impact flavor and texture.

| Feature | Description | Benefits |

|---|---|---|

| Homogenization Process | A mechanical process that breaks down particles in liquids to create a uniform mixture. | Improved consistency and stability of products. |

| Applications | Used in dairy, sauces, beverages, and pharmaceuticals. | Versatile use across multiple industries. |

| Energy Efficiency | Designed to operate efficiently, using less energy compared to traditional methods. | Cost savings and reduced environmental impact. |

| Size Reduction | Reduces the size of fat droplets and solid particles. | Enhances mouthfeel and taste of food products. |

| Quality Control | Allows for real-time monitoring of the product consistency. | Ensures high quality and reduces waste. |

When exploring valve homogenizers, efficiency and consistency emerge as primary metrics. These machines make it possible to create uniform emulsions by applying high pressure. According to a recent industry report, valve homogenizers can achieve efficiency rates above 80%. This means they significantly reduce processing time while ensuring product stability.

Consistency is also vital. The particle size after homogenization affects how products behave. Studies show that a reduction to 1 micron or smaller can enhance properties like solubility and texture. However, achieving this isn't easy. Equipment wear and variations in feed material can lead to inconsistencies. Regular maintenance is crucial, yet often overlooked.

Operators need to be vigilant. Unmonitored changes in pressure can lead to uneven results. An industry survey indicated that nearly 30% of users reported variability in their output over time. This highlights the need for a critical eye on equipment performance. Monitoring key metrics can ensure the desired results, but it demands diligence and innovation.

The future of valve homogenizer technology looks promising. Innovations are aimed at improving efficiency and product quality. Engineers are exploring enhanced designs that minimize energy consumption. This could lead to significant operational savings for many industries.

Another exciting trend is the integration of smart technology. Valve homogenizers may soon come equipped with sensors and IoT capabilities. This would allow for real-time monitoring of the homogenization process. However, implementation may come with challenges, such as data security. Companies need to weigh the benefits against potential risks.

Sustainability is also a key focus in future developments. Manufacturers are seeking eco-friendly materials for building homogenizers. This shift could reduce the environmental impact. But questions remain on material durability and performance. As these technologies evolve, continual evaluation is essential to ensure reliability and effectiveness.

: The product aims to provide essential functionality. It enhances user experience in daily tasks.

Users should follow the instructions included. Gradual practice helps in mastering its features.

A limited warranty is typically offered. Check the product documentation for details.

Some features may not work well outside. Environmental conditions could impact performance.

Troubleshooting steps are provided in the manual. If issues persist, contact support for help.

Regular cleaning is needed to ensure optimal performance. Neglecting care may lead to issues.

A Valve Homogenizer is a critical piece of equipment used in various processing industries, particularly for achieving uniformity in products. It works by forcing materials through a small valve under high pressure, which effectively breaks down particles and emulsifies mixtures. Key components such as the high-pressure pump, valve seat, and homogenizing valve play vital roles in ensuring efficient operation and consistent results.

The homogenization process not only enhances the texture and stability of products in the food and beverage sector but also improves the overall quality. Valve Homogenizers are valued for their efficiency and the ability to maintain consistency across batches, making them indispensable in production lines. As industries evolve, innovations in Valve Homogenizer technology are expected to further enhance performance, catering to the growing demand for quality and efficiency in processing applications.