You know, in the fast-changing world of scientific research, the Laboratory Homogenizer has really become a key player in driving innovation across different industries. I recently came across a report by MarketsandMarkets that said the global market for lab homogenizers is expected to jump from around $453 million in 2021 to about $600 million by 2026. That just shows how much companies want these advanced tools. Firms like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are leading the charge, focusing on high-pressure homogenizers and microfluidizers to meet the rising demand in nanotech solutions. As researchers push the limits in material science, pharma, and bioengineering, having reliable, efficient homogenizers really makes a difference—improving experimental results and speeding up innovation. They’re all about precision, versatility, and consistency, and honestly, they’re changing the way we do research entirely—shaping where science is headed next.

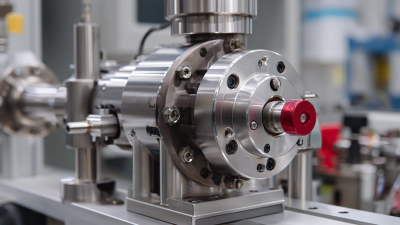

Laboratory homogenizers have really become key players in today’s research scene. They’re a game-changer when it comes to speeding things up across a bunch of scientific fields. Basically, they help mix samples evenly by breaking them down into tiny particles, so scientists get consistent results every single time. That kind of uniformity is super important—especially when working with tricky biological samples or mixes that aren’t the same throughout. Thanks to homogenizers, researchers can spend less time on prep work and more time analyzing what really matters.

Laboratory homogenizers have really become key players in today’s research scene. They’re a game-changer when it comes to speeding things up across a bunch of scientific fields. Basically, they help mix samples evenly by breaking them down into tiny particles, so scientists get consistent results every single time. That kind of uniformity is super important—especially when working with tricky biological samples or mixes that aren’t the same throughout. Thanks to homogenizers, researchers can spend less time on prep work and more time analyzing what really matters.

If you’re thinking about getting one of these machines, here are a few tips to help you make the most out of it. First off, pick the right type of homogenizer based on what you’re working with. For example, rotor-stator units are great for emulsifying, while high-pressure homogenizers are better for breaking open cells. Also, pay attention to your sample's volume and viscosity—knowing what you’re dealing with makes it easier to tweak the settings for the best results. Oh, and don’t forget—regular cleaning and proper calibration are a must. It keeps things running smoothly and keeps cross-contamination at bay.

By making the most of what these homogenizers offer, researchers can streamline their work and get more reliable data. It’s not just about speeding things up; it also pushes innovation and opens doors to new discoveries. In the end, it’s all about working smarter, not harder.

Today’s modern lab homogenizers are pretty much essential tools that really help push innovation in lots of research areas. What sets apart the high-performance ones? Well, they can consistently break down particles to really uniform sizes, give you better sample consistency, and boost extraction efficiency. Funny enough, a 2022 Market Research Report by Technavio mentions that the global market for these homogenizers is expected to grow at about 6% annually from 2022 to 2026. That just shows how much scientists are counting on these devices more and more.

One quick tip for researchers—pay attention to how the homogenizer works. You’ve got options like high-pressure homogenization and rotor-stator systems, each with their own perks. For example, if you need really tiny particles or want to disrupt cells more effectively, high-pressure systems are often the way to go. Choosing the right setup can really help optimize your results, whether you’re working in pharma, food science, or other fields.

And don’t forget about cleaning and maintenance — those details matter! Models with self-cleaning features not only save you some time but also reduce the risk of cross-contamination, which is super important when dealing with sensitive samples. If you go for advanced homogenizers with smart tech, you get real-time monitoring and control, making it easier to reproduce your results consistently. Overall, picking the right equipment really makes a difference in your research outcomes.

Choosing the right laboratory homogenizer can feel a bit overwhelming, honestly. There are quite a few factors to think about to make sure you get a model that really works for what you need. The first thing you’ll want to figure out is what kind of samples you’re working with—because, let’s be honest, not all homogenizers are created equal. Some are better suited for viscous liquids, while others do a bang-up job with solid tissues. For instance, high-pressure homogenizers are great if you need to emulsify or disperse tough samples, whereas rotor-stator ones are usually handy for processing cell suspensions or thick solutions quickly and efficiently.

Then, it’s all about scale. If you’re just doing some small experiments or routine lab work, a compact, benchtop unit might be all you need. But if you’re into bigger projects or bulk processing, investing in a solid, industrial-grade homogenizer could save you headaches down the line. Don’t forget to think about how easy it is to clean, how noisy it gets, and whether it can handle temperature control—those little details can really make a difference in how practical the equipment is for your daily work. When you get a clear picture of these factors, it’s much easier to pick a homogenizer that actually matches your research goals and helps you get better results overall.

Homogenization is pretty important across a bunch of science fields like pharma, food science, and biotech. For example, in the pharma world, lab homogenizers are used to whip up smooth emulsions or suspensions, making sure that the active ingredients are spread out evenly. Interestingly, a recent market report showed that in 2022, about 37% of the homogenizer market was just for pharmaceuticals — which kinda shows how big the demand for precise formulas and consistent quality really is.

When it comes to food science, homogenizers are like your best friends — they’re vital for producing stable sauces, dressings, and drinks. They help get the perfect texture and flavor by breaking down particles and mixing everything thoroughly. A study from the Food Processing Association even mentioned that products that went through homogenization were 30% more popular with consumers, mainly because of that better mouthfeel and improved taste.

**Tip:** When you're picking out a homogenizer, think about what materials it’s compatible with and how big your batches are. That way, you can pick the right model to get the results you want.

**Tip:** Don’t forget, keeping your lab homogenizer in good shape is super important if you want it to last and work well over time. Always clean it after use and do some calibration now and then — it keeps things running smoothly and accurately.

Laboratory homogenizers are pretty essential in today's research world—they help make sure samples are prepared consistently, which is crucial for getting accurate and repeatable results.

But, honestly, how well they perform and how long they last really comes down to proper upkeep. With just a few simple tips, you can keep your homogenizer running smoothly and extend its lifespan.

Laboratory homogenizers are pretty essential in today's research world—they help make sure samples are prepared consistently, which is crucial for getting accurate and repeatable results.

But, honestly, how well they perform and how long they last really comes down to proper upkeep. With just a few simple tips, you can keep your homogenizer running smoothly and extend its lifespan.

First off, make it a habit to clean your homogenizer thoroughly after you're done with each experiment. Leftover samples can cause contamination and mess up your next runs. Use cleaning solutions that won’t harm the device, and don't forget to disassemble and clean all removable parts carefully. Also, it’s a good idea to check for signs of wear and tear—especially on the blades and seals. Replacing worn-out parts early can save you from bigger issues down the line and avoid costly repairs.

And hey, pay attention to where and how you store your equipment. Keep it in a clean, stable environment—away from extreme heat or humidity—that makes a big difference. Regular calibration is another step that helps ensure your homogenizer performs as it should. Stick to these simple maintenance routines, and you’ll get the most out of your lab homogenizer, making your research better and more reliable.

In the ever-changing world of modern research, laboratory homogenizers are really leading the charge when it comes to innovation. I recently came across a market analysis by Grand View Research, and it showed that globally, the market for homogenizers is expected to grow pretty steadily—around 6.5% annually—from 2022 all the way to 2030. By the end of that period, we're looking at a market worth over $700 million. That’s quite a sign of how much everyone’s counting on advanced homogenization tech across different fields—think pharmaceuticals, biotech, and even food processing.

Looking ahead, the trends in homogenization are pointing toward more automation and greater efficiency. Companies are pouring resources into developing ultrasonic and high-pressure homogenizers that not only make samples more precise and consistent but also cut down on processing times. According to another report I read—this time from Technavio—adding artificial intelligence into the mix is going to make workflows smoother, boost productivity, and cut down on manual errors. It’s like a new standard for research, really. All these innovations are not just boosting what labs can do—they're opening doors for some pretty groundbreaking discoveries across various scientific areas.

| Feature | Description | Applications | Future Trends |

|---|---|---|---|

| Speed | High-speed homogenization for efficient sample processing. | Biotechnology, pharmaceuticals, and food science. | Integration with automation for enhanced throughput. |

| Consistency | Achieves uniformity in sample preparation. | Research and quality control in various industries. | Use of AI for monitoring and maintaining consistency. |

| Versatility | Compatible with a variety of sample types. | Analytical chemistry and environmental testing. | Development of multi-sample homogenizers. |

| Scalability | Easily scalable from lab to production level. | Clinical and food manufacturing processes. | Modular designs for adaptable laboratory setups. |

| User-Friendliness | Simple operation with minimal training required. | R&D labs and educational institutions. | Intuitive interfaces and smart technology integration. |

: Laboratory homogenizers are used to create uniform mixtures by breaking down samples into finer particles, which enhances efficiency and consistency in experimental results.

Uniformity is crucial for maintaining the integrity of data, particularly when dealing with complex biological samples or heterogeneous mixtures.

It's important to select the appropriate type of homogenizer for your application, taking into account factors such as sample volume, viscosity, and material compatibility.

Rotor-stator homogenizers are ideal for emulsifying, while high-pressure homogenizers excel at disrupting cells.

In pharmaceuticals, homogenization ensures that active ingredients are evenly distributed in emulsions or suspensions, which is vital for product quality and formulation precision.

In food science, homogenizers help produce stable sauces, dressings, and beverages by breaking down particle sizes and thoroughly mixing ingredients, leading to improved texture and taste.

Regular maintenance includes cleaning the device after each use and calibrating it periodically to ensure longevity and consistent performance.

Products that have undergone homogenization often receive a 30% higher consumer acceptance rate due to enhanced mouthfeel and flavor.

The pharmaceutical segment accounted for approximately 37% of the homogenizer market in 2022.

By optimizing sample preparation, homogenizers allow researchers to focus more on analyzing results rather than spending excessive time on preprocessing.

Laboratory homogenizers are pretty essential when it comes to speeding up research in so many scientific fields. Basically, they help mix samples evenly, which means you get more reliable results and studies that are easier to repeat. Today’s homogenizers come with cool features like adjustable pressure, fast processing, and better cleaning routines—all super important for keeping delicate samples safe and intact.

Picking the right homogenizer really matters if you want to match your experiments’ specific needs. From pharma to materials science, knowing how to maintain your equipment and keeping an eye on new tech trends can make all the difference for long-term success and ongoing innovation. Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about providing top-notch high-pressure homogenizers and microfluidizers to support the ever-evolving world of research—and we’re excited to be part of it.