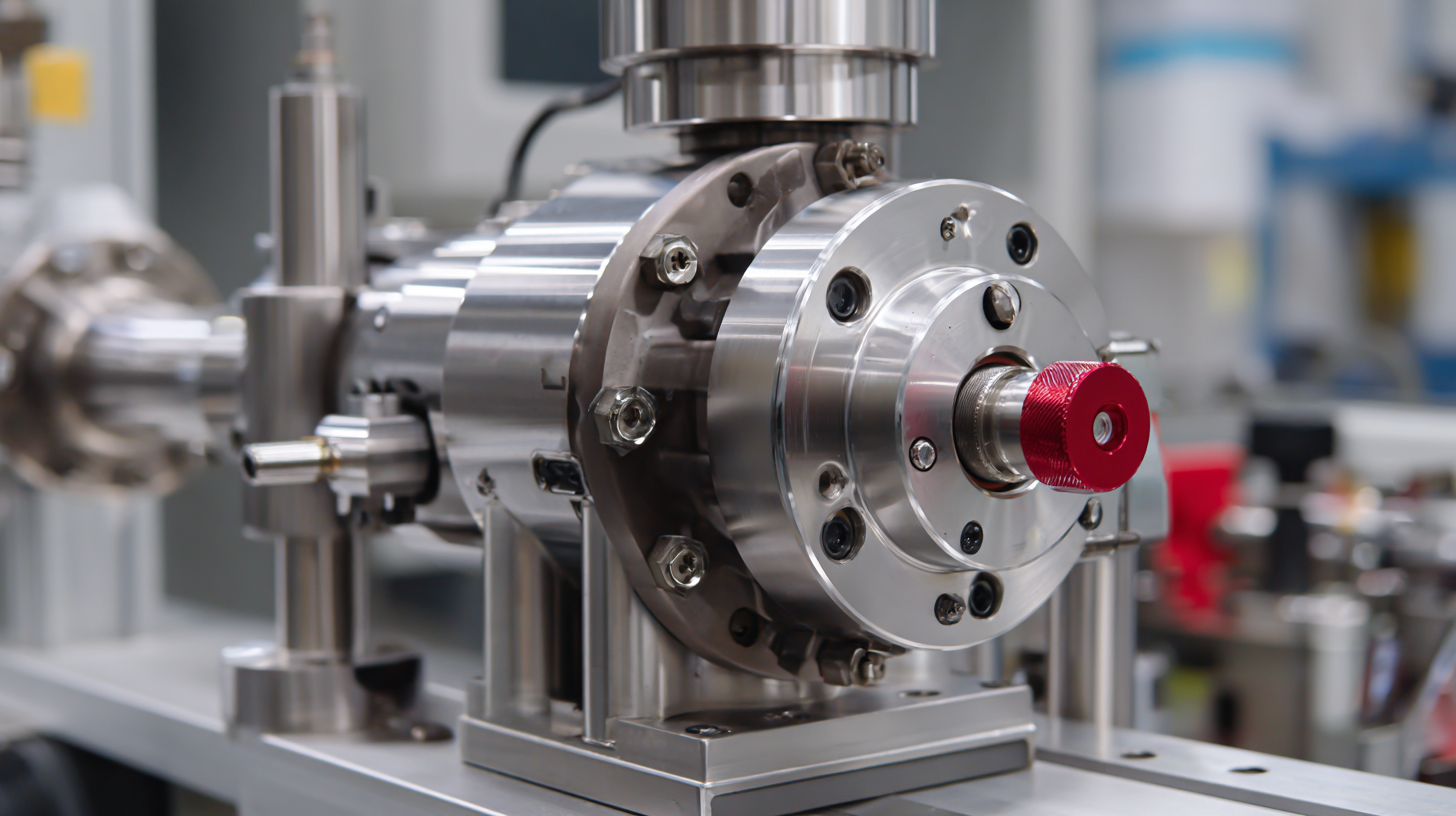

Hey there! So, in today’s fast-paced industrial world, the need for advanced processing tech has really taken off—especially in areas like nanotech and material science. One of the big names making waves in this space is the Shear Homogenizer. It’s a pretty powerful tool that helps make the homogenization process way more efficient and effective across different industries. Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about high-pressure homogenizers and microfluidizers, providing top-notch solutions tailored to fit our clients’ various needs. In this post, I want to dive into what makes the best Shear Homogenizer stand out—its cool features and how it’s super versatile. It really plays a crucial role in boosting product quality and consistency. Whether you’re working in pharma, food, or cosmetics, getting to know what shear homogenization can do for you might just take your production to a whole new level. Trust me, it’s worth the look!

Shear homogenizers have really become essential tools in many industries these days. They’re pretty amazing because they help improve product quality and keep things consistent. These high-tech devices use powerful shear forces to break down particles and emulsify mixtures, which means you get finer, more uniform dispersions—much better than standard mixing methods. Whether you're in food and beverage, pharma, or cosmetics, being able to achieve nanoscale homogenization is a game-changer, especially for improving texture, stability, and how well ingredients are absorbed. Plus, shear homogenizers don’t just perform well—they also process stuff efficiently, cutting down on production time and energy use, which is a win for everyone.

At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about high-pressure homogenizers and microfluidizers. That focus helps us create solutions that are perfectly tailored to what our clients need. Our top-notch equipment doesn’t just meet industry standards — it’s versatile enough to handle a variety of applications. Whether you're aiming to improve the texture of your food products or need better formulations for pharmaceutical suspensions, our shear homogenizers are reliable and efficient, helping you innovate and stay ahead. We’re really committed to advancing nanotechnology, and our mission is to help businesses hit their homogenization goals with confidence and ease.

Choosing the right shear homogenizer for your specific industry needs isn't always straightforward, but there are a few important things to keep in mind. First off, think about the materials you’ll be working with. Whether you're dealing with emulsions, suspensions, or really viscous products, they all need different levels of shear force to get the best results. Getting a solid understanding of your formulation is key—this way, you can pick a homogenizer that can actually deliver the desired particle size and consistency without all the hassle.

Another factor that’s often overlooked but super important is how much you need to process. If you’re running a high-volume operation, you’ll want a shear homogenizer that's efficient and built to last. Don’t forget about ease of cleaning and maintenance, either. Honestly, equipment that’s easy to disassemble and clean can save you a ton of time and headaches—plus, it helps keep your output consistent and top-notch.

**A few tips:** It’s a good idea to check out user reviews and case studies related to the models you're eyeing. Real-world experiences can be super insightful and save you from surprises. Also, think about how well the homogenizer will play along with your other equipment—smooth integration really makes a difference. And finally, don’t forget to look into the support and warranty options from the supplier. A reliable supplier who offers good tech support can make all the difference in the long run.

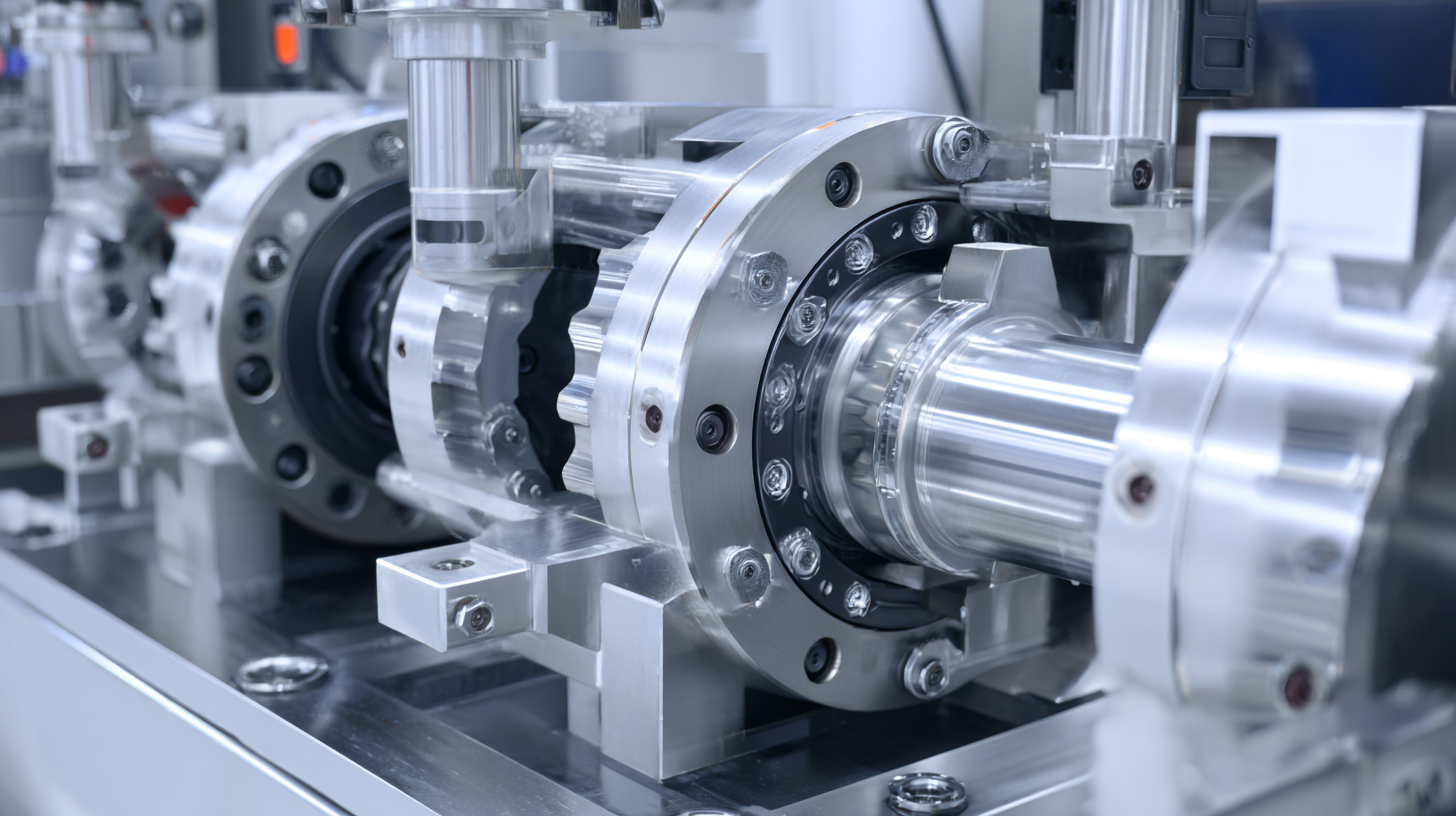

When you're looking into different mixing technologies, shear homogenizers really stand out because of their ability to create a truly uniform particle size and even dispersion. Unlike the more traditional methods that mainly rely on just stirring or agitation, shear homogenizers use powerful shear forces to break down particles and emulsify mixtures more effectively. This makes them especially valuable in industries like pharma and food processing, where consistent quality really matters.

A quick tip: when choosing a shear homogenizer, make sure it’s compatible with whatever materials you're working with—especially if you’re dealing with thick or viscous stuff. It’s a smart move to do some small-scale testing first, so you can figure out the best shear rates and processing times for your particular application.

Now, compared to other mixing options, like paddle mixers or static mixers, shear homogenizers usually do a way better job at reducing particle sizes. Paddle mixers are pretty good for blending bulk ingredients, but they might leave things a bit uneven. Static mixers, on the other hand, might struggle with thicker, viscous fluids. So, if you’re working on something that needs a high level of precision and consistency, shear homogenizers are often the way to go.

And a quick tip to keep in mind: think about your production scale and maintenance needs when picking your mix tech. Regular upkeep of your shear homogenizer isn’t just good for performance—it also helps it last longer and keeps delivering consistent results over time.

Shear homogenizers are pretty essential tools in a bunch of industries these days. They do a great job at making sure particles are evenly sized, which really boosts the overall quality of products. For instance, in pharma, they're key to whipping up stable emulsions for different drug formulations. Basically, they help spread active ingredients evenly throughout the mixture, which means better absorption and more effective medicines. But it’s not just drugs — the food industry also relies on these machines a lot, especially when making sauces, dressings, and dairy stuff. By breaking down fat globules and keeping solid bits suspended, shear homogenizers help create smoother textures and can even help products stay fresh longer.

If you’re thinking about picking out a shear homogenizer for your specific needs, keep in mind things like the viscosity of your materials, how sensitive they are to heat, and what particle size you’re aiming for. A few tips for getting the best out of your equipment? Regular maintenance is a must to avoid unexpected breakdowns, tweak the speed settings based on what you’re processing, and do some trial runs with small batches first — that way you can fine-tune everything before going full scale.

Also, making sure the machine fits well into your production setup will save you headaches down the line and help keep quality consistent. Basically, choosing the right equipment and taking good care of it can really make or break how well your product does, especially in such a competitive market.

Shear homogenizers play a pretty important role across a bunch of industries—they're essential because they help create smooth, consistent emulsions and dispersions. But, to get the most out of them and make sure they last a long time, you really gotta keep up with proper maintenance. That means regular cleaning—making sure you get rid of any buildup inside the chamber—and lubricating the moving parts so everything runs smoothly. Doing these simple things can seriously boost their performance and help avoid costly breakdowns. In fact, industry reports show that well-maintained shear homogenizers can operate up to 25% more efficiently and last longer.

Also, keeping an eye on things like pressure and temperature during operation is super helpful—it’s all about maintaining the right conditions. Being proactive on this front can save you from unnecessary wear and tear. There was even a recent study that pointed out ignoring maintenance could bump up operational costs by as much as 30% over time. So, if you stick to good maintenance routines and follow a solid schedule, you’ll keep your shear homogenizer running smoothly. That’s especially important whether you’re working in pharma, food processing, biotech, or whatever industry you're in.

Lately, shear homogenizers have really become essential tools in a bunch of industries, helping products turn out better and more consistent. For example, there's this interesting case in the food world—one of the top dairy companies started using a high-performance shear homogenizer. According to the International Dairy Federation, after they brought in this tech, their production efficiency shot up by around 30%. Not only did the milk’s texture and stability improve, but they also managed to cut down energy use by fine-tuning the emulsification process. Pretty impressive, right?

And then, there's another cool success story from the pharma side. A global drug company decided to give shear homogenizers a shot to make their vaccine formulations smoother. According to the Pharmaceutical Research and Manufacturers of America, this new homogenization tech allowed them to get a pretty tight particle size distribution (under 200 nanometers), which is crucial for the vaccine’s effectiveness. Plus, it helped them cut down the time to get new vaccines to market by about 40%. That's a huge win, showing just how much shear homogenizers can boost innovation and speed up development.

All in all, these cases really show that using shear homogenizers isn’t just about improving quality — it’s also about making the whole process more efficient and opening doors for new ideas. Honestly, it's clear this kind of tech is a game-changer for industries that are serious about excelling and staying ahead of the game.

| Industry | Application | Unique Features | Results |

|---|---|---|---|

| Pharmaceutical | Formulation of emulsions and suspensions | High shear rates and customizable rotor-stator configurations | Improved bioavailability of active ingredients |

| Food and Beverage | Homogenization of sauces and dressings | Efficient heat transfer and minimal product degradation | Enhanced textural consistency and stability |

| Cosmetics | Preparation of creams and lotions | Easy cleaning and sanitary design | Improved sensory attributes and shelf life |

| Chemical | Production of polymer emulsions | Robust construction and high throughput | Increased production efficiency and reduced waste |

| Petrochemical | Emulsion breaking and stabilization processes | Energy-efficient operation and low maintenance | Cost savings and improved process control |

: Shear homogenizers are advanced devices that utilize high shear forces to break down particles and emulsify mixtures, resulting in finer and more uniform dispersions.

Shear homogenizers are widely used in industries such as food and beverage, pharmaceuticals, and cosmetics.

Nanoscale homogenization is crucial for improving texture, stability, and bioavailability in products, particularly in pharmaceuticals and food products.

Key factors include the material being processed, desired throughput, ease of cleaning and maintenance, compatibility with other equipment, and supplier's technical support.

In pharmaceuticals, shear homogenizers create stable emulsions for drug formulations, ensuring even dispersion of active ingredients, which enhances bioavailability and efficacy.

Tips include regular maintenance, adjusting speed according to the material, testing small batches before scaling up, and ensuring compatibility with the production environment.

They achieve consistent textures and flavors in products by breaking down fat globules and suspending solid particles, leading to smoother textures and improved shelf life.

Effective cleaning and maintenance directly impact productivity and operational costs, ensuring consistent quality in output.

Businesses should evaluate the supplier's technical support and warranty options, as reliable service can significantly affect long-term satisfaction with the equipment.

Understanding the formulation is crucial to choose a homogenizer capable of achieving the desired particle size and consistency for optimal results.