When you dive into the world of advanced materials and biopharmaceutical research, you quickly realize just how essential a laboratory homogenizer really is. I mean, recent market reports are pointing out that the global market for homogenizers could hit around USD 2.7 billion by 2026. It’s pretty clear that the demand for high-pressure homogenization is skyrocketing across all sorts of industries—think food, pharma, cosmetics, and more.

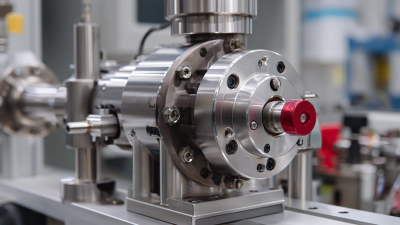

One company that’s really standing out in this space is CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD. They’re experts when it comes to high-pressure homogenizers and microfluidizers, offering some pretty cutting-edge nanotech solutions tailored to fit the specific needs of different sectors. Thanks to their innovative tech, CAS PETER is genuinely working to make lab processes more efficient and effective, really highlighting how important laboratory homogenizers have become in modern research and manufacturing. It’s a fascinating area, no doubt about it!

One company that’s really standing out in this space is CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD. They’re experts when it comes to high-pressure homogenizers and microfluidizers, offering some pretty cutting-edge nanotech solutions tailored to fit the specific needs of different sectors. Thanks to their innovative tech, CAS PETER is genuinely working to make lab processes more efficient and effective, really highlighting how important laboratory homogenizers have become in modern research and manufacturing. It’s a fascinating area, no doubt about it!

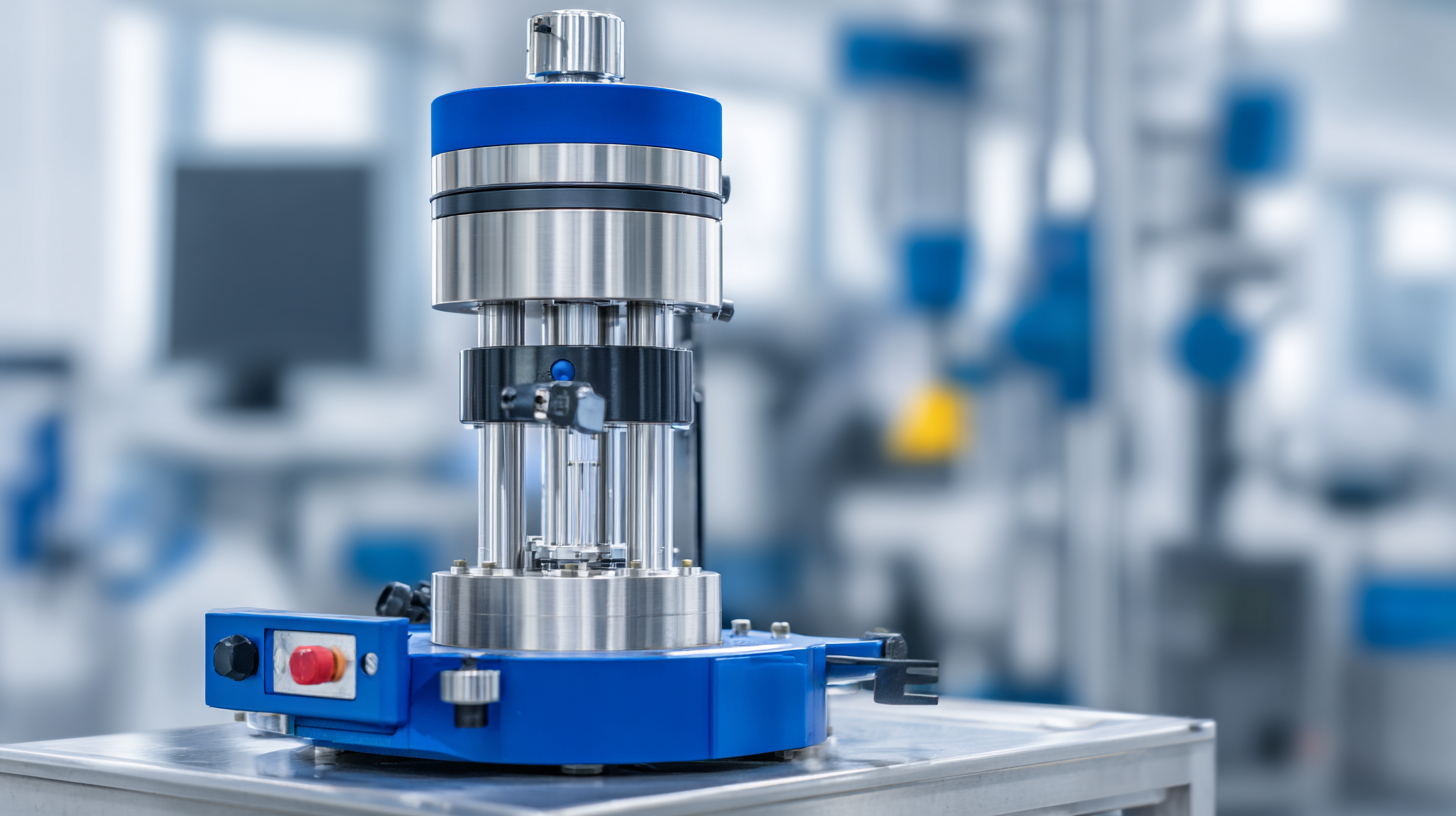

Laboratory homogenizers are pretty essential in modern research—they help make sure your samples are consistent, which means your results are more reliable. Whether you're into biochemistry, molecular biology, or material science, being able to create a uniform mixture from complex samples really makes a difference. These machines are great at breaking down cellular structures, creating emulsions, and dispersing solid particles, so scientists can analyze everything thoroughly and get accurate measurements. Honestly, this means researchers can focus on the important parts of their work without sweating over sample inconsistencies.

And it’s not just about prepping samples. Homogenizers really up your game when it comes to reproducibility and efficiency. They let you handle multiple samples at once, which saves a ton of time. Plus, many advanced models have adjustable settings, so you can tweak them to match whatever you’re working on. This kind of flexibility opens up new possibilities for researchers and encourages innovation across different scientific fields—really pushing forward our understanding and technology overall.

Laboratory homogenizers are kind of a big deal when it comes to preparing samples in many different scientific fields. Basically, they help create consistent mixtures by breaking down particles and cells—something that's pretty much essential if you want your analysis or experiments to be on point. Modern homogenizers come with features like adjustable speeds, the ability to handle multiple samples at once, and cool temperature control systems. These upgrades really boost performance and help you get reliable results, whether you're working in pharma, food science, or other areas.

If you're shopping around for a homogenizer, think about what your lab actually needs. It’s usually best to go for a model that doesn’t need a ton of maintenance—saves you time and keeps things running smoothly. Also, look for machines that are easy to operate, especially if different team members might use them. Keeping these tips in mind can make your lab more efficient and help you get consistent, trustworthy results.

Spending a bit extra on a quality homogenizer can really pay off — you’ll save time on sample prep and your experiments will turn out more reproducible. Technology’s coming out with some pretty exciting stuff lately, like ultrasonic homogenization and high-pressure techniques, which make the whole process even better. Staying up-to-date on these new features means better experiments and more successful research down the line.

Laboratory homogenizers are pretty much essential tools when it comes to preparing samples across a whole bunch of scientific fields—think biochemistry, pharma, food science, you name it. One of the biggest perks of using these gadgets is how well they help you get a uniform sample every time. I recently came across a report by MarketsandMarkets that predicts the global market for homogenizers will hit around USD 300 million by 2025. Seems like more labs are really recognizing just how crucial these tools are for getting consistent, reliable results in research and development.

But it’s not just about making samples uniform—homogenizers also seriously boost the efficiency of the prep work. Some studies suggest that using a homogenizer can cut down processing times by up to half, which is a total game-changer when you're trying to run lots of tests fast. This is especially true in high-speed environments where quick turnaround and productivity matter a lot. Plus, there are fancy models out there—like ultrasonic and high-pressure ones—that can break open cells or mix things up so thoroughly that you get really accurate extraction of analytes. All of this just proves that adding homogenizers into your lab workflow doesn’t just make things easier; it actually improves the quality of your results, too.

Laboratory homogenizers are pretty essential tools in a bunch of scientific fields. They're used almost everywhere to process samples efficiently. When folks compare different types, you'll usually hear about mechanical homogenizers, ultrasonic ones, and bead mills. If you look at a report from MarketsandMarkets, you'll see that the global market for these devices was worth around $370 million in 2022. And guess what? It’s expected to keep growing at about 5.8% annually. That just shows how more industries—like pharma, food & beverage, and biotech—are really relying on these tools more and more.

Now, mechanical homogenizers are the most common of the bunch. They use high shear forces to break things down—great for handling larger sample volumes and pretty versatile for different materials. On the flip side, ultrasonic homogenizers are known for smashing tiny particles, making them perfect for tougher samples that need a lot of energy. There was this study in the Journal of Pharmaceutical Sciences that showed ultrasonic methods can get smaller particle sizes in emulsions compared to mechanical ones, which actually helps products stay more stable. Then, there are bead mills—they’re super effective at breaking open cells, especially tough, fibrous stuff, so they’re often the go-to when you’re dealing with those kinds of materials.

Choosing the right homogenizer really depends on what you're trying to do—things like how much sample you have, how viscous it is, and what kind of end product you’re aiming for. Plus, as technology keeps evolving, these devices are only going to get better, making our research work even smoother and more efficient.

Running a lab homogenizer like a pro isn't just about pushing buttons — it's about knowing the ins and outs to get the best results every time. One of the most important things? Keeping the temperature just right during the process. You see, if things get too hot, especially with delicate samples like biological stuff, it can really mess things up. For example, experts suggest keeping samples below 10°C to protect cell health and enzyme function while you're homogenizing (Source: Journal of Laboratory Techniques, 2023).

Another thing to keep in mind is choosing the right homogenizer for what you're working with. Industry reports mention that high-pressure homogenizers do a way better job at making particle sizes consistent — a big deal in pharma and food sectors — compared to your standard mechanical stuff (Source: Global Homogenizer Market Analysis, 2023). Also, tweaking the time and pressure settings based on the sample can really boost efficiency and make your results more reliable. Basically, if you follow these best practices and make good use of technology, you'll be surprised how much you can improve your lab experiments.

Think of it like this — it's not just about tools, but about knowing how to make them work best for you. Once you get the hang of it, your results will be way more consistent and trustworthy!

| Parameter | Description | Benefits | Best Practices |

|---|---|---|---|

| Equipment Type | High shear homogenizers, ultrasonic homogenizers | Versatility in processing various samples | Select the appropriate type based on sample and application |

| Processing Speed | Variable speed control for optimal homogenization | Improved sample consistency and efficiency | Adjust speed based on sample viscosity |

| Sample Volume | Ranges from microliters to liters | Ability to process both small and large quantities | Batch processing for larger volumes |

| Temperature Control | Features to monitor and control sample temperature | Prevention of heat-sensitive compound degradation | Use cooling methods during processing |

| Cleaning and Maintenance | Ease of disassembly and cleaning | Prolongs the lifespan of the homogenizer | Regular cleaning after each use |

| Safety Features | Emergency shut-off, safety locks | Ensures user safety during operation | Follow safety protocols and guidelines |

As lab homogenization tech keeps on advancing, we're starting to see some pretty exciting trends shaping how these machines work and how effective they are. One of the coolest developments is the move towards smart technology integration. Think automated controls, real-time data monitoring, and analytics that help researchers fine-tune the process on the fly. These upgrades don't just make things more efficient—they help deliver consistent results, which is such a big deal when you're running experiments.

A pro tip here: When you're picking out a lab homogenizer, look for models that have connectivity features. Being able to log data and monitor performance remotely can really boost reproducibility and give you better control over your work.

Another trend gaining momentum is the push for more eco-friendly, energy-efficient designs. As sustainability steps into the spotlight in research facilities, makers are launching homogenizers that sip less power, are made from recyclable materials, and generate less waste. Not only does this help the environment, but it can also cut down costs for your lab.

And just a little tip: check for energy-efficient models with green certifications—they can align with your lab's sustainability goals and might even save you some money in the long run.

: Modern laboratory homogenizers feature adjustable speed settings, multi-sample processing capabilities, and advanced temperature control systems, which enhance performance and ensure consistent results across various applications.

Selecting the right homogenizer tailored to your laboratory’s specific needs can save time, reduce downtime, and improve overall efficiency when preparing samples for analysis.

Homogenizers ensure uniformity in sample preparation, which is crucial for achieving reproducible results across various scientific disciplines, including biochemistry, pharmaceuticals, and food science.

The global homogenizers market is expected to reach USD 300 million by 2025, driven by the increasing demand for precise and consistent sample processing in laboratories.

Studies indicate that using homogenizers can reduce sample processing time by up to 50%, allowing scientists to conduct experiments more swiftly.

Specialized homogenizers include ultrasonic and high-pressure models, which can effectively disrupt cellular structures and emulsify substances, ensuring thorough extraction of critical analytes.

In high-throughput environments, homogenizers enhance productivity and output quality by enabling rapid sample processing, which directly correlates with overall research efficiency.

Advancements in homogenization technology, such as ultrasonic homogenization and high-pressure processing, are becoming increasingly accessible and are refining the homogenization process.

The integration of homogenizers in laboratory protocols streamlines processes and elevates the overall quality of scientific work by ensuring consistent and accurate sample analysis.

Users should look for homogenizers with minimal maintenance requirements and user-friendly interfaces to facilitate easy operation across various skill levels.

Laboratory homogenizers are pretty much the unsung heroes of modern research. They help scientists get their samples ready quickly and reliably, no matter what field they're working in. Thanks to tech advancements, these devices now come packed with neat features that make the homogenization process not just better in quality, but also more consistent. Using a lab homogenizer has its perks—faster results, evenly sized particles, and the flexibility to handle a whole bunch of different materials. Honestly, they’ve become a must-have in many labs out there.

Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we focus on high-pressure homogenizers and microfluidizers that serve a bunch of different industries. If you follow good practices when operating these devices, you can get the most out of them. Plus, it's pretty exciting because new trends and innovations are always on the horizon—things that will push the boundaries in nanotech and other cutting-edge fields. It’s an awesome time to be in research, don’t you think?