The market for Ultra High Pressure Homogenizer technology has been changing pretty quickly lately. Companies like GEA Group, SPX FLOW, and Krones are really leading the charge here. People are craving more efficient processing methods, which is honestly pushing the whole industry to get a bit more innovative.

Looking ahead to around 2026, a few trends are starting to stand out. One big thing is the push toward sustainability and energy savings. These homogenizers are now being designed to use less energy but still boost product quality—kind of a win-win, right? It’s clear that green tech is becoming a top priority because it aligns with what the industry really needs.

That said, it’s not all smooth sailing. Some manufacturers are finding it tough to keep up with changing customer preferences. They’ve got to rethink their strategies if they wanna stay relevant and meet the demand for top-notch, consistent products. Building stronger relationships with stakeholders and pumping money into research are key steps to cracking these challenges. The market for Ultra High Pressure Homogenizers is packed with potential, but honestly, only those willing to adapt and innovate are gonna come out on top.

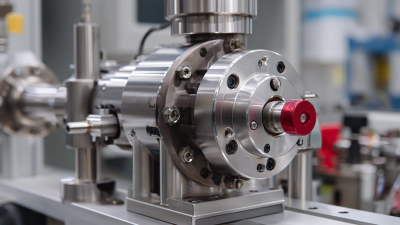

Ultra High Pressure Homogenizers (UHPH) have become essential tools in various industries. They utilize high pressure to achieve thorough mixing and emulsification. These machines can produce finer particle sizes compared to traditional methods. This leads to enhanced product stability and quality. UHPH is widely used in food processing, pharmaceuticals, and cosmetics.

The applications of UHPH are nearly limitless. In the food industry, it creates smoother textures in sauces and beverages. It also improves shelf life by reducing microbial content. In pharmaceuticals, UHPH aids in drug delivery systems. It ensures a consistent and stable formulation. The cosmetic industry benefits as well. UHPH can create stable emulsions, which enhance the performance of skincare products.

Despite the benefits, there are challenges. The initial investment for UHPH equipment can be high. Some companies may struggle with maintenance and operational costs. Staff training is another hurdle, as skilled operators are needed. Understanding the best operating conditions requires experience. Companies need to evaluate these factors carefully. Striking a balance between cost and quality is crucial for success.

The ultra high pressure homogenizer market is witnessing exciting innovations. Advanced technologies are reshaping how products are processed. These developments focus on efficiency and energy savings. Companies are investing heavily in research and development.

One key trend is the use of automated systems. These systems increase precision during production. They reduce human error and improve consistency. As a result, manufacturers can produce higher-quality products faster. This efficiency can lead to lower costs in the long run.

Tip: Always evaluate the energy efficiency of new equipment. High pressure systems can consume significant power. Look for options that offer sustainable solutions.

Another trend is the implementation of smart technology. IoT integration allows for real-time monitoring. This connectivity aids in maintaining optimal pressure levels. It can also alert operators to maintenance needs. However, relying on technology means addressing potential cybersecurity risks.

Tip: Regularly update software systems. This can mitigate security vulnerabilities. Stay informed about the latest threats in the market.

The focus on sustainability is also growing. Many manufacturers are seeking eco-friendly materials. This approach not only meets regulations but also appeals to eco-conscious consumers. Balancing innovation and responsibility is vital in today’s landscape.

Sustainability is reshaping the design of ultra high pressure homogenizers. As industries face rising environmental concerns, manufacturers seek greener solutions. This push leads to innovations that minimize energy consumption. For instance, energy-efficient motors can reduce overall operational costs. Vibrational energy recovery systems are also gaining attention.

Water usage is another critical factor. Traditional homogenization processes often waste significant water. New designs focus on closed-loop systems, reclaiming water for reuse. This shift can result in up to 50% water savings. Companies are beginning to explore bio-based materials for construction. It’s an exciting trend, but the long-term durability of these materials remains uncertain.

Recyclability is essential in design today. A seamless end-of-life plan enhances sustainability. However, many homogenizers still use non-recyclable components. This contradiction needs serious reflection. The industry's direction is promising but faces challenges. Continuous innovation is necessary, combined with a commitment to circular economy principles.

The ultra-high pressure homogenizer market is poised for significant growth by 2026. Emerging markets are driving this shift. Countries in Asia-Pacific and Latin America are showing increased demand for advanced processing technologies. A recent report projects a compound annual growth rate (CAGR) of 6.5% in these regions. This data underlines how vital these markets are to future trends.

However, challenges exist. Many companies face hurdles in technology adoption. The cost of these advanced homogenizers can be a barrier. Additionally, supply chain disruptions are also impacting potential sales. Despite these issues, the push for product quality enhancement remains strong. Businesses are increasingly willing to invest in technologies that ensure consistency and safety.

Emerging markets may present a mixed bag of opportunities and obstacles. While growth potential is high, navigating local regulations can be cumbersome. Companies must stay agile and adjust strategies frequently. Monitoring market dynamics is essential for success. With the right focus, the ultra-high pressure homogenizer industry can thrive in the coming years.

The landscape of ultra high pressure homogenizers is evolving rapidly. Key technological advancements are enhancing both efficiency and performance. Reports indicate that the global market for these devices is expected to reach $2.5 billion by 2026, reflecting a CAGR of 6.5%. This growth underscores the increasing demand for more effective homogenization in various industries.

One notable trend is the integration of smart technology into homogenizers. This allows for real-time monitoring and data analysis. Such features improve process control and product quality. Automatic adjustments based on feedback lead to higher consistency in emulsions and dispersions. A study noted that systems equipped with IoT capabilities can reduce energy consumption by up to 20%.

Despite these advancements, challenges remain. Not all facilities can afford the latest technologies. Many industry players express concerns about the high initial costs. Furthermore, operational complexity may deter smaller manufacturers. The need for skilled operators to manage sophisticated systems is evident. Bridging this skills gap is crucial as the industry progresses.

The bar chart above illustrates the projected trends for ultra high pressure homogenizers in 2026. Key dimensions include efficiency improvement, energy consumption reduction, process flexibility, cost efficiency, and market growth rate, highlighting the expected advancements in technology and performance in the industry.

The landscape of ultra high pressure homogenizer manufacturing is changing. Regulatory changes are a major factor driving these shifts. Compliance with new safety and environmental standards is mandatory. Manufacturers need to adapt quickly. This can be challenging, especially for smaller companies.

New regulations might require additional testing before a product can hit the market. This means longer processing times and increased costs. These requirements may seem daunting, yet they can also improve product safety and quality. Companies that embrace these changes can differentiate themselves.

Tips: Always stay updated with regulatory updates to avoid non-compliance. Consider engaging with industry experts to navigate these changes smoothly. Being proactive can save time and costs in the long run.

Investing in training for your workforce is crucial. Employees need to understand new standards and practices. Knowledge gaps can lead to mistakes. It's essential to foster an environment of continuous learning. Embracing innovation while ensuring compliance can be a tricky balance.

The ultra high pressure homogenizer market is evolving rapidly. By 2026, it is projected to reach a value of around $700 million, according to recent industry reports. This offers a glimpse into both the challenges and opportunities that lie ahead. With increasing demand for processed food and beverages, companies must innovate to keep pace.

However, the sector faces hurdles. Energy consumption and maintenance costs remain significant concerns. Many organizations struggle to balance high output efficiency with sustainable practices. This tension could slow growth if unresolved. Additionally, the rising complexity of manufacturing processes adds layers of difficulty. Manufacturers must train staff on new technologies, which can be resource-intensive.

Emerging markets present unique opportunities. For example, demand in Asia-Pacific is surging, driven by changing consumer habits. However, adapting to diverse regulations in different regions can be daunting. Companies may find it challenging to comply while optimizing production. Addressing these issues is crucial for capitalizing on growth potential.

| Trend | Description | Market Impact | Challenges | Opportunities |

|---|---|---|---|---|

| Sustainable Practices | Increased focus on environmentally friendly homogenizer operations. | Growing demand for green technologies in food and beverage industries. | High initial investment costs. | Potential for lower operational costs through energy savings. |

| Touchless Operation | Adoption of automation to minimize human handling. | Enhanced production efficiency and safety standards. | Need for skilled personnel to manage automated systems. | Improved worker safety and further integration of Industry 4.0. |

| Customization | Development of tailored solutions for specific applications. | Meeting diverse customer needs and preferences. | Longer development cycles for custom solutions. | Flexibility to cater to niche markets. |

| Energy Efficiency | Focus on reducing energy consumption during operations. | Lower operational costs and reduced carbon footprint. | Technological limitations in current models. | Access to government incentives for energy-efficient technologies. |

| Smart Technology Integration | Incorporation of IoT and AI in homogenization processes. | Improved monitoring, maintenance, and operational efficiency. | High costs for technology upgrades. | Ability to predict maintenance needs and reduce downtime. |

: The guide aims to provide essential information on a specific topic.

Anyone interested in the topic can gain insights and knowledge.

You can explore various online resources or community forums for deeper discussions.

Reflect on your goals and motivations. Understand the potential challenges.

Yes, many overlook preparation and end up frustrated. Planning is crucial.

Research widely and seek advice from experienced individuals in the field.

Timelines vary greatly. It's essential to set realistic goals.

Take a step back and reassess. It’s okay to seek help when needed.

Keeping a journal or log can be very effective for tracking.

Continuous learning helps adapt to changes and improves overall understanding.

The article explores the evolving landscape of Ultra High Pressure Homogenizers, highlighting their diverse applications across various industries. Key innovations are propelling the market forward, with a focus on improving efficiency and performance while also addressing sustainability trends that influence the design of these machines. As emerging markets contribute to sales projections for 2026, the industry is experiencing significant transformations driven by technological advancements.

Additionally, regulatory changes are reshaping manufacturing practices within the sector, posing both challenges and opportunities for stakeholders. The future of Ultra High Pressure Homogenizers lies in adapting to these dynamics, ensuring that they meet not only current demands but also anticipate the needs of a rapidly changing market.