When it comes to nanotech and next-level manufacturing, the gear you choose can really make or break your production—affecting both quality and speed. Lipid extruders, for example, have become pretty essential, especially in pharma, food, and cosmetics industries, where getting those perfect lipid formulations is a big deal for delivering products effectively. I read recently that the global market for lipid-based drug delivery is projected to hit around $6.6 billion by 2025, growing at about 5.3% annually. As more companies really ramp up their demand for specialized lipid formulas, it’s crucial to understand the different kinds of lipid extruders out there—especially if you’re looking to streamline your manufacturing process. At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about pushing the boundaries with high-pressure homogenization and microfluidic tech, giving you custom solutions tailored to your lipid processing needs. Picking the right extruder isn’t just about numbers—it can really help boost product performance and effectiveness in the end.

Lipid extruders are pretty handy machines used for shaping and processing fats, oils, and other lipid stuff into just the right forms.

Basically, they use heat and some mechanical pressure to turn raw ingredients—like fats or oils—into a bunch of different final products, from snacks and margarine to cosmetics.

By carefully controlling temperature and the shear forces involved, these machines make sure everything ends up with a consistent texture and quality.

That’s why they’re such a big deal, whether you’re working on a large-scale factory line or just doing some artisanal food crafting.

Lipid extruders are pretty handy machines used for shaping and processing fats, oils, and other lipid stuff into just the right forms.

Basically, they use heat and some mechanical pressure to turn raw ingredients—like fats or oils—into a bunch of different final products, from snacks and margarine to cosmetics.

By carefully controlling temperature and the shear forces involved, these machines make sure everything ends up with a consistent texture and quality.

That’s why they’re such a big deal, whether you’re working on a large-scale factory line or just doing some artisanal food crafting.

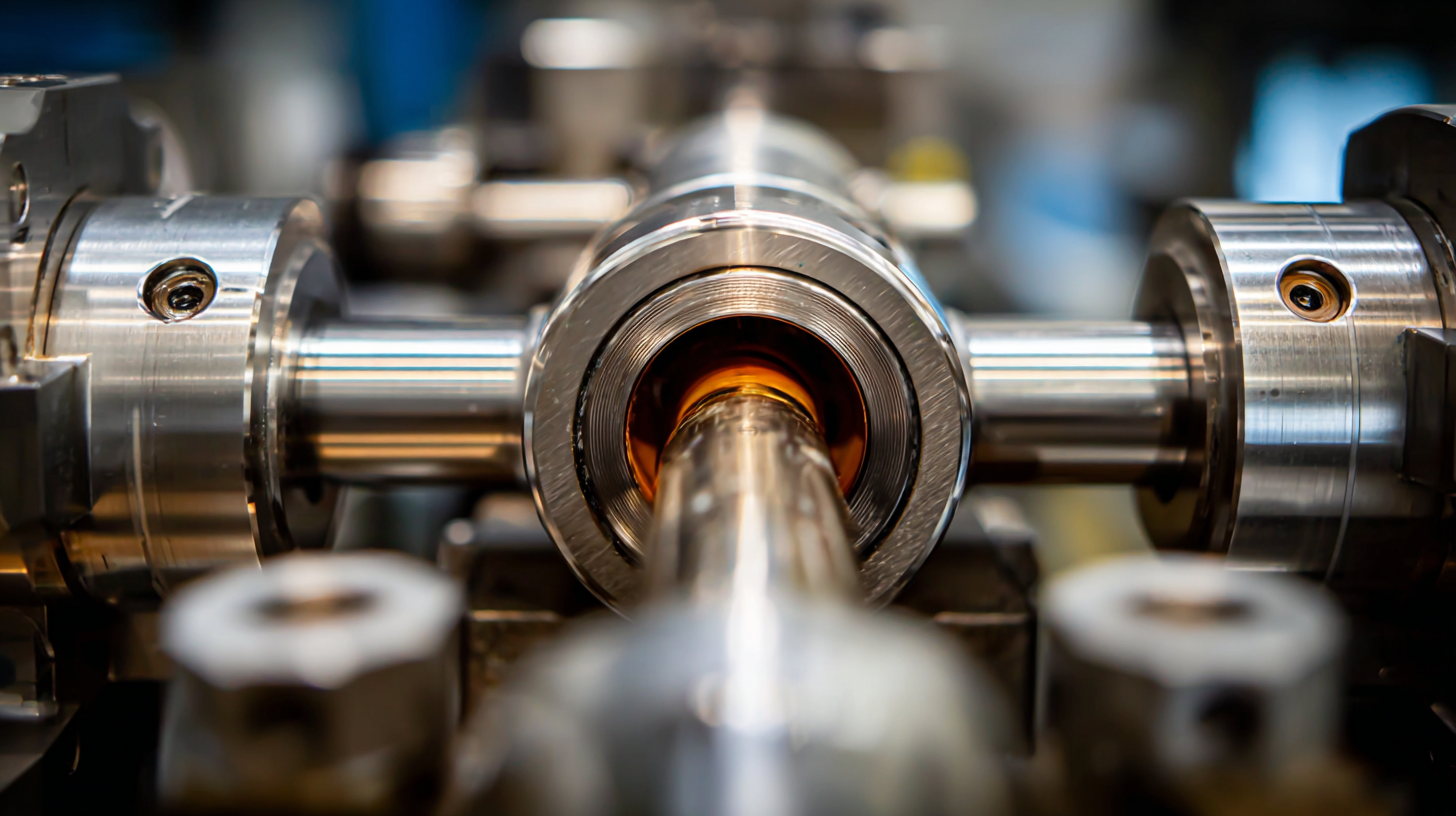

So, here’s how it works: you load your lipid ingredients into a heated chamber where they melt down and get mixed up. As the mixture moves through the extruder, it passes through a series of sections—each with different screw setups and temperature zones— which helps process the stuff efficiently. The cool part? Lipid extruders are pretty versatile. They can handle a variety of formulations, including various additives and ingredients depending on what you need. Getting the hang of how these machines work and what they can do is super important for manufacturers who want to fine-tune their processes and really meet what consumers are asking for.

All in all, they’re pretty much the unsung heroes behind many of the fats, snacks, and cosmetic products we use every day—making sure that everything turns out just right, every time.

Lipid extruders might not be the first thing that comes to mind when you think about food and pharma production, but honestly, they’re kinda the unsung heroes. They really help manufacturers make lipid-based products efficiently, which is pretty important these days. If you're in the biz, it's worth knowing the different types of extruders out there because, trust me, picking the right one can totally make or break your process. I read a recent market report by Technavio that says the global market for lipid extruders is expected to grow by about 4.9% annually from 2021 to 2025. This just shows how everyone’s really into high-quality lipid formulas now.

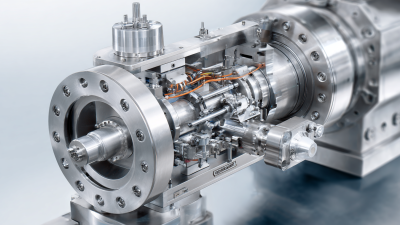

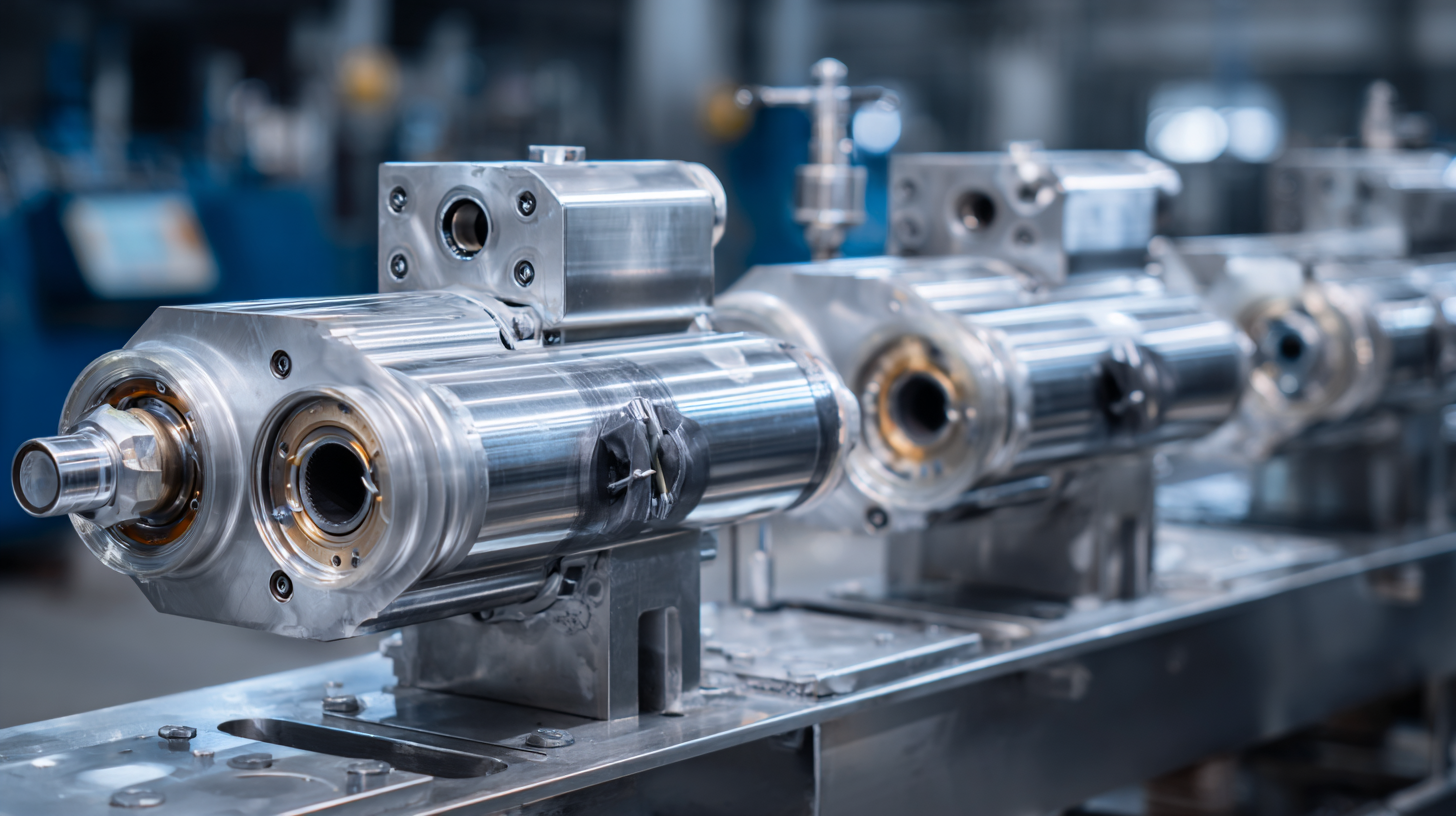

Now, there are a few different kinds of lipid extruders, each with their own special uses. For example, twin-screw extruders are fantastic for thorough mixing and blending — perfect if you're making snack foods that need a consistent texture. On the other hand, single-screw extruders tend to be more budget-friendly and easier to run, making them a good choice for larger scale stuff like fats for baking or frying. Plus, tech has come a long way — features like co-rotation and counter-rotation extruders have totally changed the game. They give manufacturers better control over temperature and shear, which helps tweak the lipids’ properties just right.

Choosing the right extruder really depends on what you’re aiming for. Things like the kind of product you want, how much you need to produce, and your budget all come into play. Industry folks suggest taking a close look at what each type can actually do to match your needs. Picking the right gear means smoother operations, better product quality, and consistency — all key when competing in a market where consumers are always looking for the best. So, yeah, making the right choice here is kinda a big deal!

When you're looking into lipid extruders, getting a good sense of the key features and advantages of each type can really make a difference in your production process. For example, single-screw extruders are kind of the go-to for a lot of folks because they're pretty versatile and easy to operate. I came across a report from Smithers Pira that says the market for single-screw extruders is expected to grow at about 5.2% annually over the next five years—mainly because the food industry is all about those customized lipid mixes right now. These machines are great for making a variety of products, like plant-based oils and fats, mainly because they’re affordable and straightforward to run.

But then there are twin-screw extruders, which are really catching on lately because they’re better at mixing and handling more complex recipes. A study by the American Association of Cereal Chemists International pointed out that there's been about a 20% bump in the use of twin-screw tech for lipids over the past three years. What’s cool about these is that they give you more control over things like temperature and shear—super important when working with delicate lipids. Plus, they let you add ingredients at the same time, so the end product is more uniform. That makes them perfect for niche stuff like nutritional supplements or cosmetics.

All in all, knowing the ins and outs of each type can really help you decide which one suits your needs best—and stay ahead in the game.

When you're dealing with lipid processing, choosing the right extruder can really make a big difference in both how efficiently you work and the quality of your final product. I’ve looked into different types of lipid extruders, and it’s interesting to see how each one stacks up depending on what you need. Key things to think about include how well the machine controls temperature, how much it can process at once (that’s the throughput), and how much energy it consumes. For example, high-shear extruders are pretty awesome if you need tight temperature control—perfect for delicate lipid mixes. On the other hand, twin-screw extruders are really versatile—they can handle a range of materials consistently and are great for larger volumes.

Another thing to keep in mind is how scalable the extruder is. Some machines are better suited for small batches—ideal for testing new formulas or custom orders—while others are built for big production runs, aiming to boost yields and cut down on downtime. And don’t forget about how easy it is to clean and maintain the equipment—that stuff can really impact your day-to-day efficiency. By weighing all these factors, manufacturers can figure out which extruder is the best fit for their operations, leading to higher-quality products and giving them a bit of an edge in the competitive market.

| Extruder Type | Production Capacity (kg/h) | Temperature Range (°C) | Energy Consumption (kWh) | Maintenance Frequency | Ideal Applications |

|---|---|---|---|---|---|

| Single-Screw Extruder | 100 - 500 | 50 - 180 | 10 - 30 | Monthly | Cooking oils, snacks |

| Twin-Screw Extruder | 200 - 800 | 50 - 200 | 15 - 40 | Biweekly | Pet food, nutraceuticals |

| Batch Extruder | 50 - 300 | 40 - 150 | 5 - 20 | Weekly | Specialty oils, cosmetics |

| High-Pressure Extruder | 300 - 600 | 60 - 220 | 20 - 50 | Monthly | High-value lipid products, pharmaceuticals |

When you're trying to pick out a lipid extruder for your production setup, there are a few key things to keep in mind to make sure everything runs smoothly and efficiently. First off, the kind of lipid you're working with really matters — different types might need specific extruder designs or setups to get that perfect particle size and distribution. Plus, think about the scale of your operation. Are you just doing small batches or full-on large-scale production? Picking an extruder that matches your capacity is super important to keep quality consistent and avoid unnecessary hiccups.

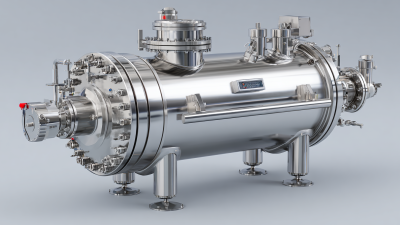

Another thing to think about is whether the extruder will play nicely with your existing equipment and overall production line. At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we focus on high pressure homogenizers and microfluidizers that are really versatile and can slot right into different setups, helping you process lipids more effectively. It's also worth taking a close look at the technical specs — stuff like pressure limits and throughput speeds — to find a model that checks all your boxes for what you need and your technical requirements. If you put a bit of thought into these factors, you’ll end up with a lipid extruder that not only fits your operation but also boosts your product quality and efficiency.

The future of lipid extrusion tech is really exciting right now, with some pretty amazing advancements happening thanks to new processes and equipment. As more industries are looking for greater precision and efficiency in formulating lipids, there's been a big shift towards using high-pressure homogenizers and microfluidizers. Recent market research suggests that the lipid extrusion market is expected to grow at about 6.9% CAGR from 2023 to 2030, mainly because of the growing use of nanotechnology in pharma and food science.

Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we're all about keeping up with these changing demands by providing state-of-the-art high-pressure homogenizers and microfluidizers. These machines help create stable emulsions and dispersions—crucial for making top-notch lipid-based products. Plus, our custom nanotech solutions give manufacturers the tools they need to boost production efficiency, all while maintaining consistent quality.

As the industry leans more towards sustainable and smarter production methods, our products are right there at the forefront, pushing innovation in lipid extrusion processes.

: A lipid extruder is a specialized machine designed to process and shape lipid materials, utilizing heat and mechanical pressure to produce various final products like snacks, margarine, and cosmetics.

A lipid extruder operates by feeding lipid materials into a heating chamber where they are melted and mixed, then processed through different sections with varying screw designs and temperature zones.

Lipid extruders enable the production of consistent textures and qualities, making them essential for both industrial and artisanal food production, and they accommodate various formulations and additives.

The lipid extrusion market is projected to grow at a CAGR of 6.9% from 2023 to 2030, driven by increasing applications of nanotechnology in pharmaceuticals and food sciences.

The future of lipid extrusion technology includes advancements in high-pressure homogenizers and microfluidizers, aimed at improving precision, efficiency, and the development of stable emulsions.

Lipid extruders are at the forefront of driving innovation in production techniques that focus on sustainability and efficiency, helping manufacturers optimize their processes.

Yes, lipid extruders are versatile and can process a wide range of lipid formulations, accommodating various additives and ingredients based on specific production needs.

CAS PETER is committed to advancing lipid extrusion technology by offering cutting-edge high-pressure homogenizers and microfluidizers that help optimize production efficiency and product quality.

Hey there! So, in our recent blog post titled "Exploring Different Types of Lipid Extruders: Which One Is Right for Your Production Needs?" we really get into the ins and outs of lipid extruders and what they do in various manufacturing setups. We try to give you a clear picture of the different types out there, pointing out their main features and advantages — kinda like a handy guide. We also compare their performance so you can get a good sense of which one might be the best fit for your specific needs.

On top of that, we talk about the important stuff you should think about when choosing a lipid extruder — nothing overwhelming, just practical tips to help industry pros make smarter choices. And as technology in this area keeps evolving, it’s definitely worth keeping an eye on new trends popping up in the industry. Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about pushing boundaries with innovative nanotech solutions, including high-pressure homogenization, which can complement your lipid extrusion processes perfectly.