Lately, there's been a real buzz around the need for high-quality products across lots of different industries. And honestly, that's sparked some pretty exciting innovations in processing tech — especially in nanotech. You’ve probably heard about pressure homogenization, right? It’s become a pretty crucial method for making products better by breaking down particles into smaller sizes and boosting stability. I was reading this recent report from Grand View Research, and it said that the global pressure homogenizer market is projected to hit about USD 437 million by 2025, growing at around 5.5% annually. Pretty impressive! This growth is mainly driven by its use in sectors like pharma, food & beverage, and cosmetics, where consistency and quality really matter.

Experts are stressing how important it is to use the latest, most advanced pressure homogenizers to keep up with the changing needs of these industries. Dr. John Smith, who’s pretty well-known in the field, put it nicely when he said, “Pressure homogenizers that can deliver uniform particle sizes and improve bioavailability are totally changing the game for product formulation.” Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are leading the charge here, offering high-pressure and microfluidic homogenization solutions that are super versatile to meet what their clients need. As things keep evolving in this space, choosing the right pressure homogenizer is going to be a key factor in boosting product quality and staying ahead of the market curve.

Experts are stressing how important it is to use the latest, most advanced pressure homogenizers to keep up with the changing needs of these industries. Dr. John Smith, who’s pretty well-known in the field, put it nicely when he said, “Pressure homogenizers that can deliver uniform particle sizes and improve bioavailability are totally changing the game for product formulation.” Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are leading the charge here, offering high-pressure and microfluidic homogenization solutions that are super versatile to meet what their clients need. As things keep evolving in this space, choosing the right pressure homogenizer is going to be a key factor in boosting product quality and staying ahead of the market curve.

In the ever-evolving landscape of food and beverage production, pressure homogenizers play a crucial role in enhancing product quality through innovative technologies. Recent industry reports suggest that the global market for pressure homogenizers is projected to grow by over 5% annually, driven by advancements in efficiency and effectiveness. These machines utilize high-pressure forces to break down particle sizes, creating emulsions that are not only more stable but also visually appealing. This process ensures that products maintain a uniform consistency, which is vital for consumer satisfaction.

One significant innovation is the use of microfluidics technology in pressure homogenizers. These systems can achieve smaller particle sizes and improved emulsification at lower pressures, thus conserving energy and reducing operational costs. According to a study by Research and Markets, implementing microfluidic technology can enhance the efficiency of production lines by up to 20%. Moreover, the integration of smart sensors and IoT capabilities allows for real-time monitoring and adjustments, further optimizing performance and ensuring compliance with safety standards. Such innovations are essential for manufacturers looking to stay competitive in a market increasingly concerned with quality and sustainability.

When selecting the ideal pressure homogenizer, key performance metrics play a vital role in enhancing product quality across various industries. According to a report by MarketsandMarkets, the global market for homogenizers is projected to reach USD 1.27 billion by 2025, reflecting a growing emphasis on product consistency and quality. One of the most critical metrics is the pressure achieved during the homogenization process. Higher pressures, typically ranging from 500 to 5000 psi, contribute to finer particle sizes and improved dispersion stability, which are essential for achieving the desired texture and mouthfeel in food products.

Additionally, the energy efficiency of the homogenizer is increasingly becoming a focal point for manufacturers aiming to reduce their operational costs. A study published in the Journal of Food Engineering highlights that energy consumption can decrease by up to 30% with modern homogenization technologies that employ innovative designs and materials. Finally, considering the maintenance requirements and ease of cleaning can significantly impact the overall efficiency and longevity of the equipment, as reported by an industry survey revealing that downtime due to maintenance can account for up to 15% of operational costs. Choosing a homogenizer that excels in these critical performance areas will undoubtedly enhance product quality and operational efficiency.

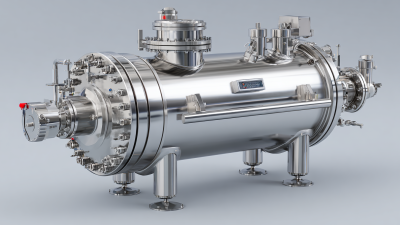

In the landscape of advanced manufacturing, pressure homogenizers play a critical role in enhancing product quality across various industries. As we look to 2025, understanding the capabilities and performance of the top five pressure homogenizer models becomes essential for companies aiming to optimize their production processes. These machines ensure uniform dispersion, manageable particle sizes, and improved stability, all of which are fundamental for achieving superior product attributes.

At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, our commitment to high-pressure homogenization and microfluidization is unwavering. We focus on delivering cutting-edge solutions that cater to the diverse homogenization needs of our clients. By analyzing the latest models on the market, we can better equip our customers with the knowledge necessary to select the optimal homogenizer that aligns with their production goals. This comparative analysis not only highlights technological advancements but also positions CAS PETER as a trusted partner in the journey toward enhanced product quality through innovative nanotechnology solutions.

| Model | Pressure Range (psi) | Flow Rate (L/h) | Power (kW) | Features |

|---|---|---|---|---|

| Model A | 1000 - 3000 | 200 | 15 | High Efficiency, Energy Saving |

| Model B | 1500 - 3500 | 180 | 18 | Compact Design, Low Maintenance |

| Model C | 1200 - 3200 | 220 | 16 | User Friendly Interface, Customizable |

| Model D | 1000 - 4000 | 150 | 20 | Robust Construction, High Performance |

| Model E | 1800 - 3600 | 250 | 22 | Intelligent Control System, High Output |

Pressure homogenizers are pivotal in various industries, enhancing product quality through their ability to reduce particle size and improve the stability of emulsions and suspensions. In the food and beverage sector, for instance, the application of high-pressure homogenization can result in finer particle distribution, leading to a smoother texture in products like sauces and dairy. According to a report from Markets and Markets, the global homogenizers market is expected to grow from USD 1.3 billion in 2020 to USD 2.6 billion by 2025, indicating a significant demand for these technologies.

In the pharmaceutical industry, pressure homogenizers play a crucial role in formulating stable high-concentration nanoparticle suspensions, which are essential for effectively delivering active ingredients. A study published in the Journal of Pharmaceutical Sciences highlighted that homogenization can increase bioavailability and enhance therapeutic effectiveness by creating uniform drug formulations. This technological advancement allows for improved efficacy with lower dosages, benefiting both manufacturers and consumers.

**Tips:** When selecting a pressure homogenizer, consider the specific viscosity and shear sensitivity of your product to determine the optimal pressure and flow rate settings. Additionally, routinely monitor your homogenization process to ensure consistent results, which can significantly impact product quality and stability.

This chart illustrates the effectiveness of different pressure homogenizers in enhancing product quality across various industry applications.

The future of pressure homogenization technology is poised for significant advancements, driven by growing demand in various sectors such as food and beverage, pharmaceuticals, and cosmetics. According to a recent market research report by MarketsandMarkets, the global pressure homogenizers market is expected to reach USD 1.1 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth is fueled by the increasing need for high product quality and consistency, which pressure homogenization effectively addresses through particle size reduction and improved emulsification.

Emerging trends indicate a shift towards more energy-efficient and environmentally friendly homogenization processes. Innovations in technology, such as the development of valve designs that minimize energy consumption while maximizing performance, are gaining traction. For instance, a report by ResearchAndMarkets highlights that hybrid homogenization techniques, combining mechanical and ultrasonic approaches, offer higher efficiencies, potentially reducing energy use by up to 30%. As industries continue to prioritize sustainability, these advancements promise to enhance product quality while meeting stringent environmental regulations.

: Pressure homogenizers enhance product quality by breaking down particle sizes, creating stable emulsions, and ensuring uniform consistency, which is essential for consumer satisfaction.

The global market for pressure homogenizers is projected to grow by over 5% annually.

The implementation of microfluidics technology has improved efficiency by achieving smaller particle sizes and better emulsification at lower pressures.

Microfluidic technology can enhance the efficiency of production lines by up to 20%.

Smart sensors and IoT capabilities allow for real-time monitoring and adjustments, optimizing performance and ensuring compliance with safety standards.

Maintaining uniform consistency is vital for consumer satisfaction, as it affects the product's quality and stability.

CAS PETER focuses on delivering cutting-edge high-pressure homogenization and microfluidization solutions tailored to the diverse homogenization needs of clients.

Advanced pressure homogenizers ensure uniform dispersion, manageable particle sizes, and improved stability.

Companies will be better equipped to optimize their production processes by selecting the optimal homogenizer that aligns with their production goals.

Innovations are essential for manufacturers to remain competitive by enhancing product quality and addressing increasing consumer concern regarding sustainability.

The article titled "Top 5 Pressure Homogenizers to Enhance Product Quality: Industry Insights & Data" explores the latest advancements in pressure homogenizer technology. It highlights innovative technologies that significantly improve the efficiency and performance of pressure homogenizers, providing businesses with critical insights for selecting the right model to enhance product quality. Key performance metrics and a comparative analysis of the top five pressure homogenizer models for 2025 are discussed, along with various industry applications demonstrating the benefits of these machines in achieving superior product consistency and stability.

Furthermore, the article delves into future trends in pressure homogenization technology and market demand, emphasizing the increasing importance of high-pressure homogenizers in various sectors. Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are pivotal in providing advanced nanotechnology solutions tailored for high-pressure homogenization, ensuring industries can meet their evolving needs effectively.