The cosmetics world is always changing, right? And one thing that’s super important is keeping product quality and consistency on point. That’s where a high-performance Cosmetics Industry Production Homogenizer really comes into play. Over at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about pushing the boundaries with advanced high-pressure homogenizers and microfluidizers tailored specifically for cosmetics. We’re passionate about helping cosmetic brands streamline their processes — making sure emulsions and suspensions stay stable and keep that great texture.

In this blog, I’ll share some key tips and proven strategies to optimize homogenization. Trust me, these insights can really make a difference in boosting product quality and making production more efficient.

You know, emulsion stability is kinda a big deal when it comes to cosmetics. It totally impacts how the product feels, works, and even how long it lasts on the shelf. Funny enough, recent reports show that about 70% of cosmetic products are emulsions — no surprise there, right? It really highlights how important it is to have good stabilization techniques up your sleeve. If you're looking to improve emulsion stability, a good trick is to consider natural emulsifiers from plant sources. Not only do they often perform better, but they also sync well with the whole clean beauty trend that’s really taken off. I remember reading in the Journal of Cosmetic Science that products using plant-based emulsifiers had about 30% more stability compared to those with synthetic ones — pretty impressive, don’t you think?

**Tip:** When you're picking out emulsifiers, don't forget to check the HLB value — that's basically a number that tells you if it’s right for your specific oil-water mix. Making sure it's spot-on can really boost your emulsion's stability and overall performance.

Another neat trick is to optimize your homogenization process. Using high-shear mixers can break down droplet size pretty significantly, which makes your emulsion much more stable. In fact, industry stats show that reducing droplet size to under 10 microns can bump up stability by 50% or even more! Plus, it’s not just about looks — smaller droplets also mean the product resists separating over time way better.

**Tip:** Keep an eye on the temperature while you’re homogenizing. Keeping it steady can make the emulsification process run smoother and help all those active ingredients stay just right.

By trying out these tips and tricks, formulators can totally up their game and create emulsions that are not just stable, but also really meet what consumers are craving: high-quality, innovative products that actually work.

When it comes to cosmetics, the particle size distribution—or PSD—really matters quite a bit in how the final product turns out. Having particles that are pretty uniform in size doesn’t just make the product feel nicer on your skin; it also helps keep things stable and makes active ingredients work better. For example, finer particles can boost how well certain formulas react and penetrate, making moisturizers and anti-aging treatments more effective.

On the flip side, if the particle sizes vary a lot, you might end up with a texture that feels gritty or uneven—trust me, nobody wants that on their face!

And it’s not just about looks or feel. PSD actually influences how long your beauty products last and how stable they stay over time. Bigger particles tend to settle at the bottom, causing separation in things like emulsions, while those tiny particles can clump together, which is pretty annoying. To avoid these issues, manufacturers use techniques like high-pressure homogenization or microfluidization to get the particle sizes just right—sort of like perfection in a bottle. By dialing in the right process, they can make sure the product stays consistent, works well, and feels great for the user—that’s us getting the best bang for our buck!

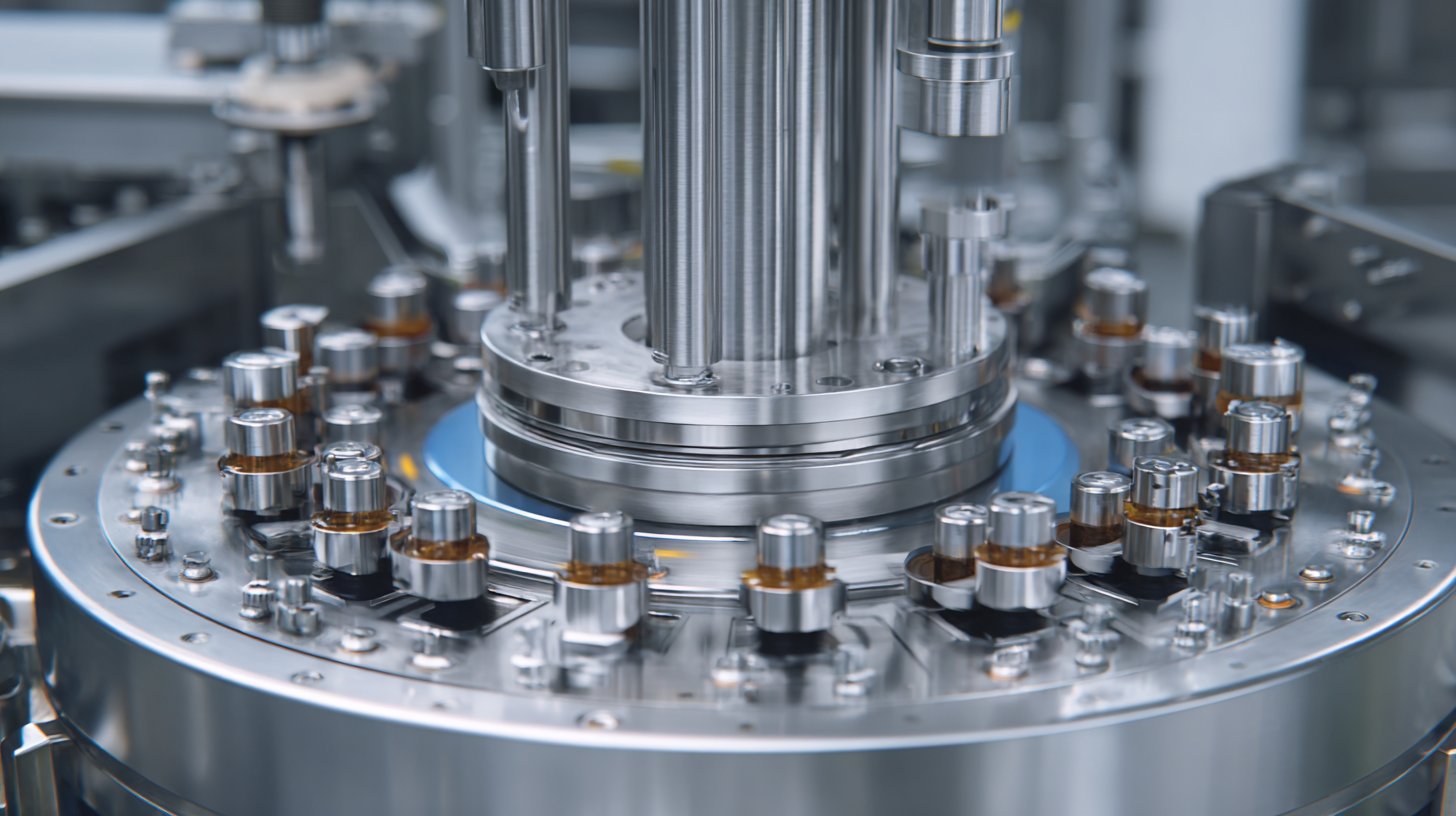

You know, the cosmetics world is really going through some exciting changes right now, thanks to new homogenization equipment that’s actually making manufacturing way more efficient. Recently, tech has come a long way — for example, those fancy triple shaft mixers are a game-changer. They do a great job at dispersing powders evenly, even when dealing with tricky formulations that used to give manufacturers headaches. This shift in how homogenization is handled is super important, especially as brands aim for consistent quality and better performance in their products.

According to the latest market reports, the global market for homogenizers was valued at around USD 1.62 billion in 2023. And guess what? It’s expected to keep growing at a pretty solid rate — about 5.3% annually from 2024 to 2030. That really shows how much demand there is for these advanced machines — they’re key to ensuring that cosmetic products are uniform and stable. When manufacturers adopt these new technologies, not only do they streamline their production, but they also boost the overall quality of their products, which helps them stay competitive in such a crowded market.

Getting the homogenization just right in the cosmetics world really is a big deal for making sure products turn out great and work well. One of those key tricks? Keeping the temperature just right. If you’re not careful with the heat during mixing, the ingredients might not blend evenly, which can mess with the texture, thickness, and overall stability of the product. When you maintain a steady temp, it reduces the chance of ingredients separating and really helps oil and water mix better. That results in a smoother, more effective product that feels just right.

Temperature control isn’t just about the texture; it also matters for active ingredients. Some of those supercharged compounds can be pretty sensitive to heat, so keeping the temp in check is crucial to make sure they stay potent and do their thing. For instance, vitamins and botanical extracts that degrade easily need very particular conditions during mixing. Using advanced temperature monitoring systems can really help brands stay in control, leading to higher quality products that meet what customers are hoping for. By focusing on managing temperature well, formulators can make products more consistent and effective, which means happier customers in the end.

Measuring how well homogenization works is super important for cosmetic brands that want to keep their products consistently great in quality and performance. Things like particle size, viscosity, and how stable the emulsion is—those are the key factors that tell us how well the ingredients are blending together to make a stable product. When you keep an eye on these things, you can make sure your products not only pass all the regulatory checks but also meet what consumers are really craving—high-quality cosmetics that look and feel amazing.

Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re passionate about pushing the limits of homogenization. We use the latest high-pressure homogenizers and microfluidizers to help cosmetic formulators get perfect results. Our tech gives you precise control over particle sizes and how they're distributed—so ingredients are evenly spread out. That means your products work better and look better too, which really helps with customer satisfaction and keeps people coming back for more.

| Metric | Description | Typical Value Range | Importance |

|---|---|---|---|

| Droplet Size Distribution | Measurement of the size and distribution of particles in the emulsion | 1-100 microns | Critical for stability and texture |

| Viscosity | Resistance of the formulation to flow | 500-5000 cP | Affects application and feel |

| Stability Testing | Observing the product's performance over time under various conditions | 3-12 months | Ensures long-term efficacy and safety |

| pH Level | Acidity/basicity measurement of the formulation | 4.0-7.5 | Influences skin compatibility and preservative efficacy |

| Emulsion Type | Identifies if the emulsion is oil-in-water or water-in-oil | Varies by formulation | Determines sensory and delivery characteristics |

You know, in the world of cosmetics, making sure products have a nice, even texture and stay stable over time can really come down to having the right homogenization methods. Take this one skincare brand, for example—they were having a tough time with their emulsions, where the oil and water kept separating. But once they started using these advanced high-shear mixers, everything changed. The creams turned out way more stable, kept their consistency, and customers noticed the difference, leading to fewer returns and happier buyers. Plus, being able to control the shear rates precisely meant they could create tiny, uniform droplets—super important for that rich, luxurious feel we all love in skincare products.

Then there’s a cool story from a makeup company that was having trouble dispersing pigment in their liquid foundations. They decided to go with a three-step homogenization process—pretty high-tech! First, they used rotor-stator mixers and then moved on to a high-pressure homogenizer. This combo didn’t just boost the color brightness; it also made the product work better overall. The result? Better coverage, smoother application, and just a way better product that set a new standard in the industry for quality and performance.

All in all, these tweaks with homogenization really made a big difference—not just for the brands involved but for what customers can expect from their favorite skincare and makeup products.

: Emulsion stability is critical as it directly impacts a product's performance, texture, and shelf life, with reports indicating that nearly 70% of cosmetic formulations are emulsions.

Natural emulsifiers derived from plant sources can provide superior stability compared to synthetic ones, with studies showing a 30% increase in stability.

Formulators should pay attention to the HLB (Hydrophilic-Lipophilic Balance) value to ensure it is suitable for the oil-to-water ratio in their formulations.

Reducing droplet size to less than 10 microns can enhance emulsion stability by 50% or more, improving visual appeal and resistance to separation.

Maintaining a consistent temperature during homogenization ensures uniform blending of ingredients, affecting viscosity, stability, and overall texture.

Advanced homogenization equipment enhances manufacturing efficiency and product consistency, driving innovations in the cosmetics industry.

Proper temperature control is crucial for preserving heat-sensitive compounds like vitamins and botanical extracts to prevent degradation.

The global homogenizers market was valued at approximately USD 1.62 billion in 2023 and is expected to grow at a CAGR of 5.3% from 2024 to 2030, indicating high demand for advanced homogenization technologies.

By prioritizing temperature management and implementing advanced temperature monitoring systems during the homogenization process, formulators can enhance product quality and meet consumer expectations.

Advanced techniques optimize production processes, ensure uniformity and stability in cosmetic products, and help brands improve overall product offerings.

Hey, if you’ve ever peeked into the cosmetics world, you know that getting the perfect mix really matters. This blog’s all about the key tricks for keeping emulsions stable in your formulations. One thing that’s super important is how particle size distribution can make or break your product — so, controlling that accurately during manufacturing is kind of a big deal. Modern homogenization equipment? It’s a game-changer, making the whole process way more efficient. Also, temperature control is pretty much essential if you want those results to turn out just right. Plus, measuring how well the homogenization goes—using some key metrics—can really make a difference in how your final product performs.

We’ve included some real-world stories from companies that nailed their homogenization strategies — showing off how innovations like high-pressure homogenizers and microfluidic tech are pushing the boundaries in the beauty industry. As a leader in this field, CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is all about delivering top-notch solutions to meet these exciting new needs in cosmetic manufacturing.