In the fast-moving worlds of nanotech and materials science, there’s been a real spike in the need for better processing methods. Small homogenizers are now pretty much essential across a bunch of different fields. I recently read that the global market for homogenizers could hit around $2.1 billion by 2025. That’s mainly because they’re so important in making sure stuff like pharmaceuticals, food, and biotech products are top quality. These tiny homogenizers are key for getting consistent particle sizes and making products more stable—ultimately, helping formulations work better.

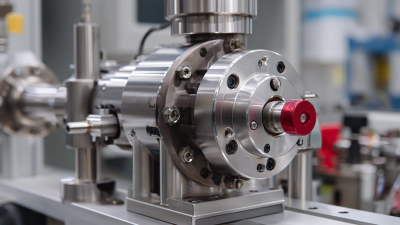

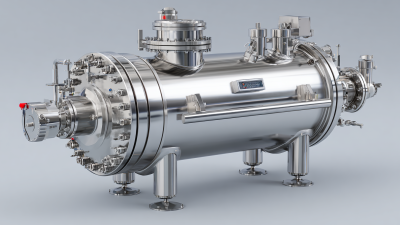

CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is a real leader in high-pressure and microfluidic homogenization, and they get just how crucial small homogenizers are for industry. They’re constantly pushing out innovative tech designed for different sectors, so they can meet the high standards needed for great results and keep driving product development forward.

CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is a real leader in high-pressure and microfluidic homogenization, and they get just how crucial small homogenizers are for industry. They’re constantly pushing out innovative tech designed for different sectors, so they can meet the high standards needed for great results and keep driving product development forward.

Small homogenizers might not be the most glamorous gadgets out there, but they honestly play a huge role in lots of industries, especially in food and pharma. Basically, these devices help mix things evenly by breaking down particles to a uniform size, which is super important for keeping products consistent and stable. I came across a report from Grand View Research that says the global market for homogenizers is projected to hit around $1.29 billion by 2025. That just shows how much people are craving equipment that guarantees their products turn out just right.

In the food biz, small homogenizers are pretty much the secret behind making smooth, well-blended ingredients. They help with emulsification, which means better textures and flavors. There’s even a study in the Journal of Food Science mentioning that good emulsification can help sauces and dressings last longer. So, naturally, consumers are loving products that are nicely blended without weird separation. On the pharma side, getting the particle size just right through homogenization is a game-changer because it makes sure medications deliver effectively. The World Health Organization has pointed out that precise dosing is critical in drug manufacturing, which just highlights how vital small homogenizers are for meeting those strict standards and making sure everything works as it should.

Small homogenizers really play a huge role when it comes to shrinking down particle sizes in all sorts of formulations—think pharmaceuticals, food, drinks, and cosmetics. I came across this report from TechSci Research that predicts the global market for these devices will hit around $1.1 billion by 2025. That growth’s mainly driven by folks wanting products that are more consistent and stable. These small homogenizers, usually holding between 0.1 to 0.5 liters, are built to make sure ingredients mix evenly by breaking down particles and boosting things like bioavailability.

One of the coolest things about these little gadgets? They can crush particles down to nano and micro sizes, which pretty much supercharges the stability and effectiveness of emulsions and suspensions. There was a study in the Journal of Pharmaceutical Sciences showing that reducing particle size can bump up the surface area by as much as 300%. That means faster absorption and better therapeutic results. Plus, they’re pretty energy-efficient and don’t cost a ton to run—so they’re perfect for small to medium-sized labs and pilot setups, according to Frost & Sullivan. All in all, using small homogenizers helps manufacturers whip up high-quality products that meet strict rules, while also saving time and money in the process.

You know, small homogenizers have really become quite the game-changer across different industries. They're a lot more effective than older methods like just using mechanical blenders or stirrers. Essentially, these little devices use high-pressure forces to ensure particles are evenly sized and substances are mixed thoroughly. When you actually compare how well they work versus traditional techniques, the difference is pretty noticeable. For instance, small homogenizers can cut down processing times quite a bit because they reach that perfect, uniform mixture much faster than your average mixer. That means not only do things get done quicker, but it can also save a bunch on operational costs too.

What’s more, these tiny homogenizers are great at delivering consistent, high-quality results. Old-school methods often give you uneven particle sizes or incomplete mixes, which can really mess with the final product's quality. With small homogenizers, you get the advantage of precise control over pressure and speed, so you end up with uniform results every time. That’s especially important in fields like pharma or food production, where maintaining strict standards isn’t just a bonus but a must for safety and satisfying customers. Overall, adding small homogenizers to the process really boosts productivity and quality, making them a smarter choice compared to the old methods.

Small homogenizers might sound like pretty technical equipment, but they actually play a really important role in making sure products stay stable across a bunch of different industries—think pharmaceuticals, food, cosmetics, you name it. Basically, they help mix ingredients evenly by creating consistent emulsions and dispersions. This is especially crucial when you're working with liquids that don’t naturally mix well, since these tiny devices produce much finer droplets that boost stability and keep everything from separating out over time. When they do their thing, the high shear forces break down particles into tiny, almost invisible sizes—sometimes down to sub-micron levels—which results in smoother textures and a nicer look for your products.

On top of that, small homogenizers also help active ingredients become more effective and easier for our bodies to absorb. When formulations are properly emulsified, each component is evenly spread out, making sure nutrients or medications do their job properly. This is particularly useful in cosmetics too—think of creams or serums that need a stable emulsion to hydrate skin better and deliver active ingredients effectively. All in all, small homogenizers aren’t just fancy gadgets—they’re pretty much essential for industries that want to improve product quality, consistency, and stability.

Adding small homogenizers into your manufacturing process can really make a difference—like, it can boost efficiency and improve product quality almost instantly. Yeah, I know the upfront cost might seem a bit intimidating at first, but honestly, when you look at the long-term gains, it usually pays off. When the particles are evenly sized and the texture stays consistent, your products become more stable, and customers tend to be happier. That can mean better sales and a stronger spot in the market, which is always a win.

If you're trying to figure out whether investing in a small homogenizer is worth it, consider comparing the ongoing costs and maintenance with your current mixing methods. Plus, there's the bonus of less waste and fewer reworks because your product ends up more uniform. And let's not forget, these machines can speed up your production process. Faster cycles mean more output and, ultimately, more profit.

Of course, it’s also super important to think about what your specific needs are. Picking the right small homogenizer that fits your particular line can help you get the most bang for your buck without spending money on stuff you don’t need. And hey, keep revisiting your processes now and then—regular checks can make sure your investment keeps paying off over time.

| Dimension | Value | Benefit |

|---|---|---|

| Processing Speed | 1000 rpm | Increased production rate |

| Capacity | 10 liters/hour | Enhanced scalability |

| Energy Consumption | 0.5 kWh | Cost-efficient operation |

| Investment Cost | $5,000 | Quick return on investment |

| Maintenance Frequency | Once a year | Reduced downtime |

| User Training Duration | 2 hours | Faster employee onboarding |

Small homogenizers might not be the most glamorous piece of equipment out there, but trust me, they’re pretty important—especially when it comes to keeping everything compliant with regulations across different industries, like food and beverage manufacturing. The market for these guys is really growing; experts say it'll jump from about $1.2 billion in 2024 to around $1.8 billion by 2033. That just goes to show how crucial it is to have reliable equipment that can keep products consistent and top-quality. These small homogenizers help manufacturers hit those tiny details—like making sure particle sizes are uniform and emulsions stay stable—which, honestly, are key to both safety and quality in food products.

But it’s not just food stuff where they’re making waves. They’re becoming super important in some pretty high-tech areas, like making nanomedicines based on PLGA. Scaling up these advanced medicines isn't exactly a walk in the park, and getting the particles just right is a big part of the challenge. That’s where good homogenization techniques come into play—they help keep everything uniform and effective. Plus, regulatory agencies are pretty strict about the standards in pharma—so these homogenizers are basically essential tools to help manufacturers stay on the right side of the rules, all while making sure their products are reliable. As industries keep evolving, having small homogenization equipment on hand is going to be a game-changer for navigating all those regulatory hoops without breaking a sweat.

: Small homogenizers are used for particle size reduction in formulations, particularly in pharmaceuticals, food and beverage, and cosmetics, enhancing product consistency and stability.

They optimize emulsification and dispersion by creating finer droplets, which reduces separation and enhances the uniform mixture of ingredients, leading to smoother textures and visual appeal.

By breaking down particles to nano and micro sizes, small homogenizers enhance the bioavailability and efficacy of active ingredients, ensuring better absorption in formulations that require uniform distribution.

The global homogenizer market is expected to reach USD 1.1 billion by 2025, driven by the need for improved product consistency and stability.

Small homogenizers ensure uniform particle size, improve product texture, enhance stability, reduce waste and rework, and can lead to increased sales due to higher consumer satisfaction.

They offer lower operating costs and energy efficiency, making them an ideal solution for small to medium-scale production, which can save manufacturers time and resources.

Factors to consider include comparing operational costs with traditional methods, the potential for reduced waste, and the specific needs of the production line to maximize efficiency.

Particle size reduction increases surface area, which can lead to faster absorption rates and improved therapeutic effects in various applications, including pharmaceuticals and cosmetics.

By improving processing times and ensuring product consistency, small homogenizers can lead to faster production cycles and greater overall profitability for manufacturers.

They help achieve stable emulsions that improve skin hydration and the delivery of active compounds, thereby enhancing the effectiveness of cosmetic products.

Small homogenizers are pretty much essential in many industries these days. They really help speed up the process of breaking down particles in different formulations. What’s cool is that they can produce a really even dispersion and create smooth emulsions, which boosts the stability of the final product. Honestly, they’re a bit of a game-changer for manufacturing. Compared to older, more traditional methods, these tiny homogenizers are way more efficient—meaning companies save money and end up with a better product overall.

Bringing small homogenizers into the mix doesn’t just help with efficiency; it also ensures you’re meeting all those strict regulatory standards. Plus, it makes the whole production process run much smoother. Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are top-notch when it comes to offering advanced high-pressure homogenization and microfluidization tech. This way, industries can easily stay on top of their nanotech needs without a hassle.