In today’s fast-changing world of manufacturing, choosing the right equipment isn’t just a minor detail — it’s actually a game-changer for making sure your products come out top-notch and your processes run smoothly. One tool that really stands out in this scene is the Blade Type Homogenizer. You’ll find it popping up in all kinds of industries — from pharma and cosmetics to food processing. If you looked at market research reports, like one from Grand View Research, they’re saying that the global market for homogenizers could hit around 1.87 billion dollars by 2025. That’s mainly because more folks are demanding high-quality emulsions and suspensions these days.

Over at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about offering cutting-edge solutions in high-pressure homogenization and microfluidization — making sure manufacturers get access to the very best tech to suit their needs. Think of this guide as your go-to for understanding how to pick the perfect Blade Type Homogenizer. We’ll walk through the key technical specs and practical tips that can really make a difference in your manufacturing results.

Over at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about offering cutting-edge solutions in high-pressure homogenization and microfluidization — making sure manufacturers get access to the very best tech to suit their needs. Think of this guide as your go-to for understanding how to pick the perfect Blade Type Homogenizer. We’ll walk through the key technical specs and practical tips that can really make a difference in your manufacturing results.

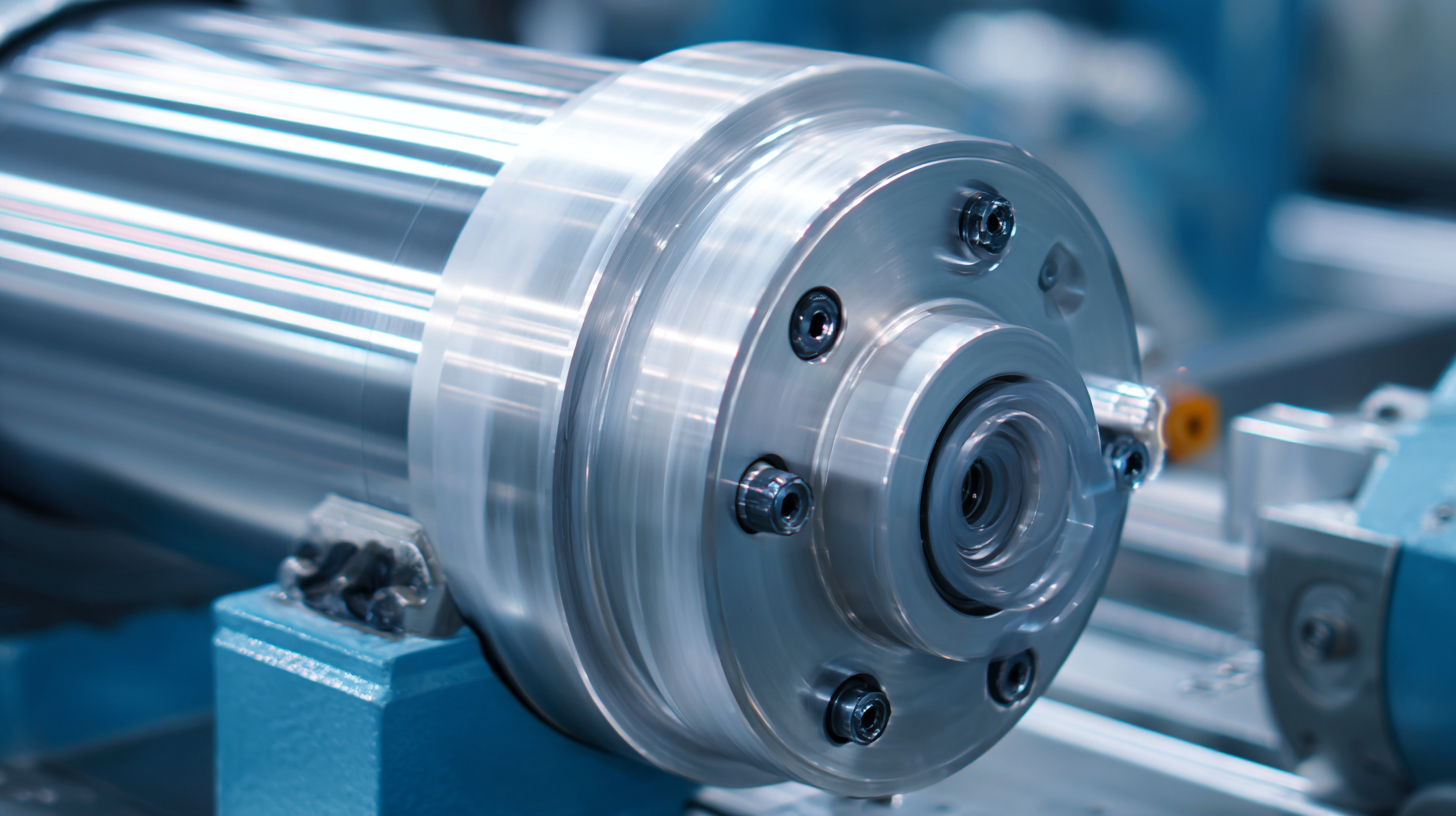

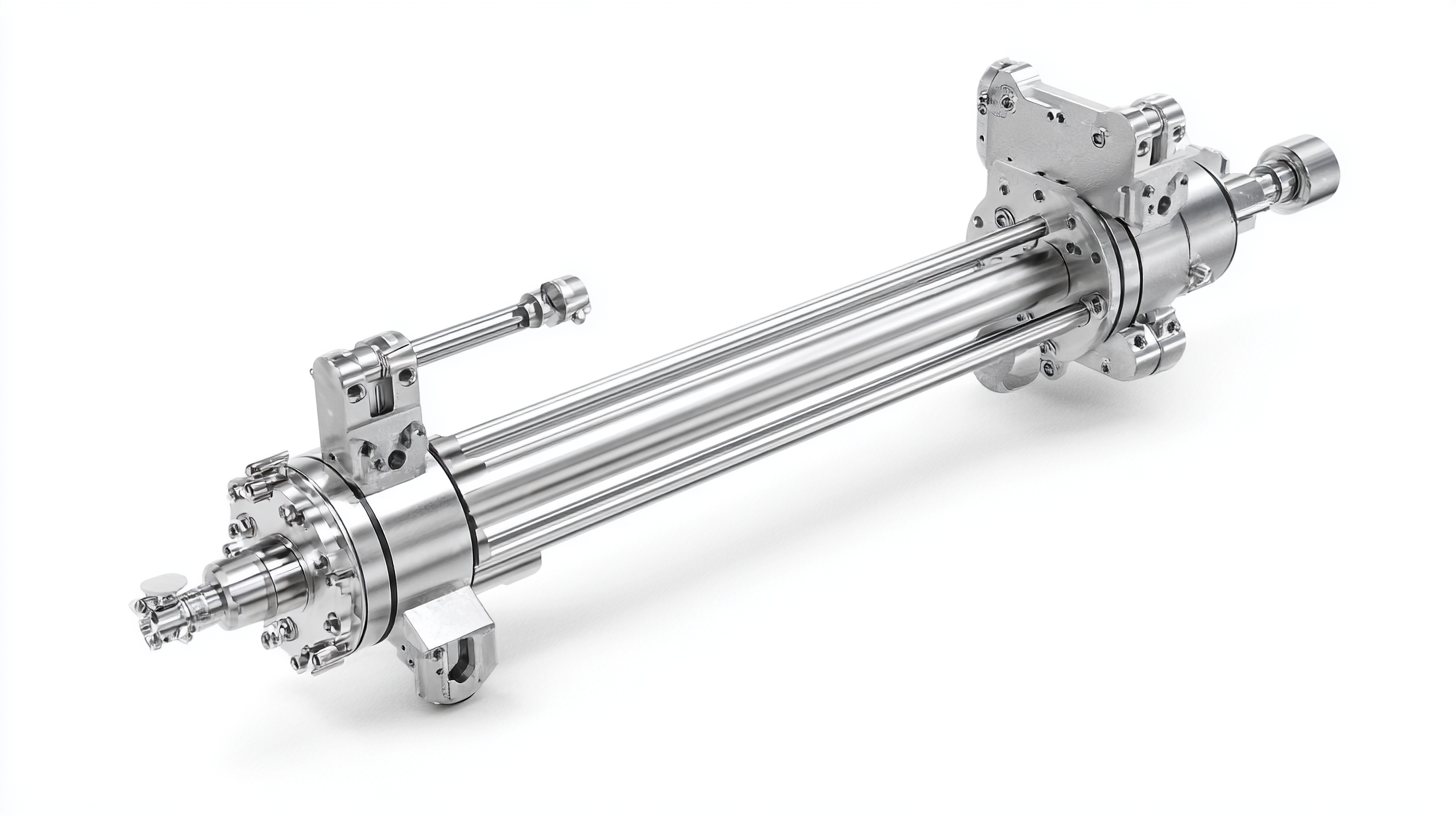

When you're picking out a blade type homogenizer for your manufacturing setup, there are a few important stuff you gotta think about. First off, the material of those blades really makes a difference — it affects how well it works and how long it lasts. Most folks go for stainless steel because it doesn’t rust easily and is super easy to clean, which is a big plus if you're dealing with stuff that needs to stay super hygienic. Also, the design of the blades matters — whether they’re fixed or adjustable. Having adjustable blades gives you some extra wiggle room to handle different viscosities and various products without a headache.

Then again, you gotta consider how big or small your operation is. The capacity of the homogenizer should match how much you’re actually producing. If you’re running a small setup, a compact model that fits in seamlessly is probably your best bet. But if you’re running a bigger, more industrial setup, you’ll want something that can handle continuous operations without breaking a sweat. Don’t forget about the cooling system and how energy-efficient the machine is, too — because those factors can directly impact your running costs. In the end, choosing the right blade type homogenizer isn’t just about equipment—it’s about making your products more consistent and high quality while keeping things efficient and cost-effective in the long run.

As the manufacturing world keeps changing, it’s pretty exciting to see what’s coming in blade tech for homogenizers by 2025. These new trends are all about meeting the growing demands across different industries. One big thing to watch is how high-pressure homogenization is becoming even more powerful — it’s actually making a real difference in how well reconstituted dairy powders dissolve and how they behave when you’re processing them. People have seen that under high pressure, these powders fully dissolve and flow almost like fresh concentrates. That’s a game-changer when it comes to keeping product quality consistent.

Plus, there’s some cool stuff happening with blade design itself. The latest innovations aim to make the process more efficient and precise. Studies are showing that clever new blade shapes can generate better shear rates, which means smaller particle sizes and more stable emulsions overall. And as manufacturers move toward using more high-protein formulas, choosing the right type of blade becomes even more critical. It’s all about making sure those ingredients disperse properly and give you that perfect texture — which, let’s be honest, really matters for keeping customers happy.

Staying on top of these trends is super important for companies wanting to step up their game. Incorporating these advanced blade technologies isn’t just about keeping up — it’s about staying ahead in a competitive market and meeting what consumers are looking for today and tomorrow.

| Blade Type | Efficiency (%) | Mixing Speed (RPM) | Material Compatibility | Temperature Range (°C) | Application Sector |

|---|---|---|---|---|---|

| High-Shear Blade | 95 | 5000 | Plastic, Metal | -20 to 100 | Pharmaceuticals |

| Rotor-Stator Blade | 90 | 3000 | Glass, Metal | 0 to 150 | Food Processing |

| Ultrasonic Blade | 85 | 25000 | Ceramics, Glass | -40 to 80 | Biotechnology |

| Static Blade | 75 | 1500 | Metal | -10 to 70 | Cosmetics |

| Dual-Shear Blade | 92 | 4000 | Plastics, Composites | -10 to 120 | Chemical Industry |

When you're trying to pick out the best blade type homogenizer for your manufacturing needs, it's really important to get a good grasp of the different blade designs and what they’re best suited for. Every industry has its own specific requirements when it comes to homogenization, and choosing the right blade design can make a huge difference in getting the results you want. For example, recent studies really show that rotor-stator homogenizers are fantastic at breaking down particles to the nanometer scale—perfect for cosmetics and pharma applications. These types use intense shear forces to mix and emulsify ingredients, which helps keep the final product stable and uniform.

On the other hand, high-pressure homogenizers are great when you need gentle handling, like in food processing, where keeping delicate components intact is super important. According to a report from MarketsandMarkets, the worldwide market for these high-pressure units is expected to hit around $500 million by 2025—so, they’re becoming pretty essential across different industries. CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is also in the game, offering innovative solutions tailored to a wide range of sectors, from pharma to food. By understanding the pros and cons of various blade designs, manufacturers can make smarter choices that boost their process efficiency and upgrade product quality — it’s all about making those informed decisions!

When you're trying to pick out the best blade type for your homogenizer needs in manufacturing, it’s pretty important to get a good handle on efficiency and performance. Homogenizers are really key for making sure your products are uniform, whether you’re dealing with liquids, creams, or emulsions. The trick is starting with a solid understanding of your material’s properties and what particle size you’re aiming for. Things like blade design, how fast it spins, and the setup of the homogenization chamber all play a role in how well the process works. For example, high-shear blades are great at breaking down tough particles and creating finer emulsions, which is a big deal if your formulations need high stability.

Plus, you really wanna consider how big your operation is. Different production scales might require different capacities, so matching your equipment to your volume can make a big difference in how much you can produce efficiently. And don’t forget about maintenance and operational costs — choosing a homogenizer with sturdy parts could save you a lot of hassle (and money) down the line. By taking a close look at all these factors, manufacturers can make smarter choices about their homogenizers, making sure everything runs smoothly and that they get the quality they’re after in their final products.

If you want your blade-type homogenizer to last longer and perform at its best, it's super important to keep up with regular maintenance. Things like inspecting and cleaning it often are pretty much must-dos. I’ve seen reports that neglecting these steps can actually cut down its efficiency by around 20% over time, which is a pretty big deal. Honestly, giving it a good clean after each use really helps prevent residue from drying out and messing with the blades. Just make sure to use a cleaning product that won’t corrode the materials—the ultimate goal is keeping everything hygienic and in good shape.

Also, paying attention to how sharp your blades are is a game changer. Dull blades end up needing more power to run, which can bump up your operating costs. Some recent studies suggest that sharpening or swapping out blades every 6 to 12 months can slash energy consumption by up to 15%, although of course it depends on what you’re processing. Oh, and don’t forget about lubrication! Giving the moving parts a bit of oil regularly can really cut down on friction and reduce wear and tear, helping your machine last way longer. Basically, sticking to these simple maintenance tips means your homogenizer stays efficient, lasts longer, and that’s good news for your productivity and your budget in the long run.

Choosing the right blade-type homogenizer for your manufacturing setup is super important if you want to maximize efficiency and keep your product quality top-notch. It’s a good idea to do a bit of a cost-benefit analysis—that way, you can see whether investing in a high-quality machine makes sense in the long run, compared to just going for a cheaper option. Sure, the upfront cost might be higher, but things like durability, smooth operation, and better results often make it worth the extra bucks. When you’re shopping around, think about things like how much output you need, maintenance ease, and what specific tasks the homogenizer will handle.

Here’s a tip: really take some time to evaluate your production needs. If you’re expecting your volume to grow, it might be worth splashing out on a more advanced model now—saves you headaches and cash down the line. Also, don’t forget to check out energy consumption ratings; an energy-efficient machine can cut down your costs over time.

And one more thing—look into the support and spare parts availability. A reputable brand might cost a bit more, but it can save you money by reducing downtime and keeping things running smoothly. Always ask about warranty options and after-sales support, so you’re covered if anything goes sideways. Bottom line: investing thoughtfully now can make all the difference later on.

: Stainless steel is commonly preferred for homogenizer blades due to its resistance to corrosion and ease of cleaning, making it ideal for manufacturing environments where hygiene is important.

The design of the blades, whether fixed or adjustable, can significantly impact the homogenization process. Adjustable blades offer flexibility to operate under varying viscosities and product types.

Manufacturers should ensure that the capacity of the homogenizer aligns with their production volumes. Small-scale operations may benefit from compact models, while larger facilities might require high-capacity, continuous operation designs.

Energy efficiency is crucial as it can directly influence operational costs. An energy-efficient homogenizer can lead to significant cost savings in the long term.

Rotor-stator homogenizers are highly effective in reducing particle sizes down to the nanometer range, making them suitable for applications in cosmetics and pharmaceuticals due to their ability to disperse and emulsify materials.

High-pressure homogenizers are ideal for food processing applications as they excel in maintaining the integrity of delicate components while requiring minimal shear.

A cost-benefit analysis should consider factors like output capacity, maintenance requirements, specific applications, and the potential long-term gains from investing in a high-quality homogenizer over cheaper alternatives.

Evaluating energy consumption ratings is important as an energy-efficient homogenizer can lead to cost savings over time, contributing to overall operational efficiency.

It's essential to consider the availability of technical support, spare parts, warranty options, and after-sales support, as these can mitigate risks and reduce downtime in production.