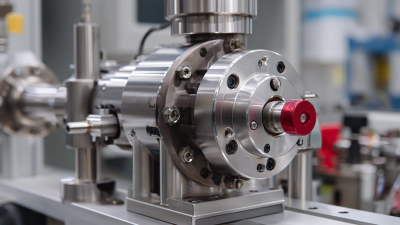

You know, in today’s fast-moving world of manufacturing, it feels like there's always something new around the corner, especially when it comes to stuff like nanotechnology. I’ve read that the global market for nanotech is expected to hit around $125 billion by 2024 — pretty crazy, right? That growth is really fueled by all kinds of innovations across different industries. One cool example is the Nanometer Liposome Extruder. It’s a pretty important tool that helps make liposomal products more consistent — like getting the size just right and boosting stability. CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, a major player in high pressure homogenizers and microfluidizers, really gets how vital this tech is for all sorts of industries. With tools like the Nanometer Liposome Extruder, manufacturers can improve drug delivery systems, craft better cosmetic products, and create top-notch nutritional supplements. Essentially, it’s all about giving companies that extra edge in this competitive market — pretty exciting stuff, honestly.

Nanometer liposomes are these tiny, almost invisible vesicles that actually play a huge role in today's manufacturing world, especially when it comes to pharma and cosmetics. They’re usually made of phospholipids and act like little carriers for drugs and active ingredients. What’s cool about them is that they boost how well these ingredients get absorbed by the body and keep them stable for longer. Basically, they wrap up sensitive compounds in their bilayer membranes, protecting them from breaking down so they can do their job properly once they reach their target. Because they're so small, they can sneak into cells more easily, making them super useful for delivering meds or active ingredients where they need to go.

Nanometer liposomes are these tiny, almost invisible vesicles that actually play a huge role in today's manufacturing world, especially when it comes to pharma and cosmetics. They’re usually made of phospholipids and act like little carriers for drugs and active ingredients. What’s cool about them is that they boost how well these ingredients get absorbed by the body and keep them stable for longer. Basically, they wrap up sensitive compounds in their bilayer membranes, protecting them from breaking down so they can do their job properly once they reach their target. Because they're so small, they can sneak into cells more easily, making them super useful for delivering meds or active ingredients where they need to go.

In manufacturing, using a nanometer liposome extruder really helps streamline things and makes the final product better. It allows manufacturers to control the size and uniformity of the liposomes with pretty fine precision—something that’s pretty important for making sure every batch performs consistently. This means better effectiveness of the products, more stability, and, of course, happier customers. Plus, all these advances in nanotech open up the door for creating innovative formulations that can meet really specific consumer needs. So, in a way, it gives companies a bit of an edge in a pretty competitive market.

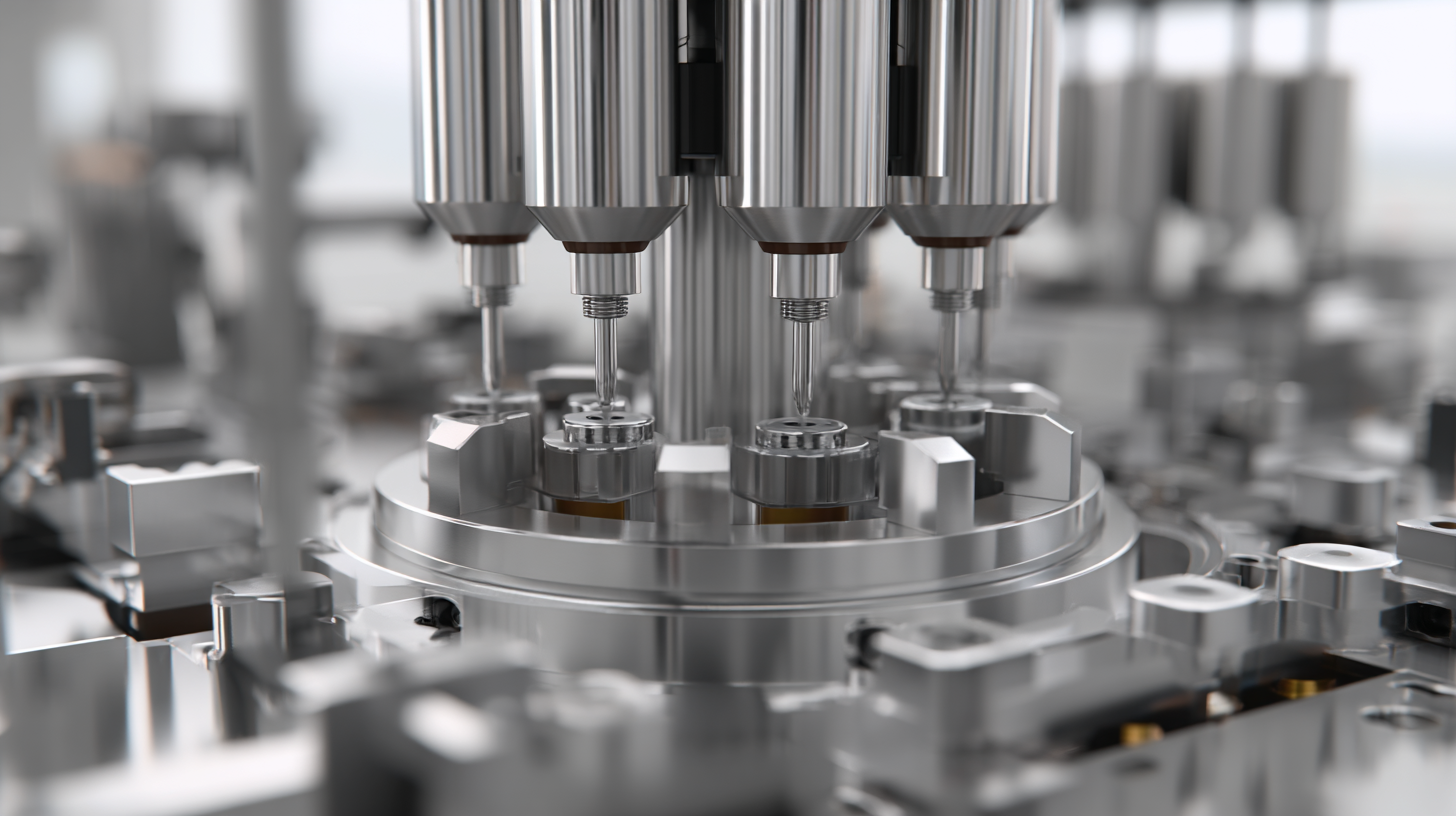

Liposome extrusion is pretty much a game-changer when it comes to delivering both water-loving (hydrophilic) and fat-loving (hydrophobic) drugs. It's become a key part of modern manufacturing, really pushing the boundaries of what's possible. Basically, the science behind it involves using microfluidic systems—think of tiny, precise channels—that give researchers tight control over the size and make-up of the liposomes. Recently, there's been some exciting progress: using pre-made multilamellar liposomes seems to boost how much low-solubility drugs can be packed inside. Studies have shown that whether these liposomes are kept fresh or frozen, they still do a great job at being loaded with different formulations, showing how versatile they are for pharma stuff.

Over time, the way we prepare liposomes has also gotten better. Techniques like thin-film hydration and microfluidic production are now in the mix. For example, one study highlighted how microfluidics can be used to make enzyme-loaded liposomes—achieving encapsulation rates as high as 95% with certain formulations, which is pretty impressive. This is especially promising for treatments targeting inflammatory diseases. Plus, there's this whole new thing with hybrid exosomes—these are basically exosomes fused with liposomes—offering a really cool way to deliver drugs more precisely. These innovations don’t just mean more stable and efficient drug delivery; they also help extend the shelf life of liposome formulations, which is pretty important when you're dealing with critical meds.

Nanometer liposome extruders have really become essential tools in today’s manufacturing world, especially in the pharma and cosmetics industries. They come with some pretty great advantages that can seriously boost the quality and efficiency of your products. For instance, one of the key perks is their ability to produce liposomes with very precisely controlled sizes. That means your formulations are more uniform, which not only helps the active ingredients get absorbed better but also keeps the products stable for longer periods.

That said, when you're working with a nanometer liposome extruder, it's super important to keep an eye on the extrusion pressure. Cranking it up can give you smaller liposomes, which is often desirable, but too much pressure might end up damaging delicate compounds. Temperature control is another biggie — making sure you stay at the right temperature during the process helps protect those active ingredients and keeps everything intact. Oh, and don’t forget regular maintenance on your extruder! It might seem like a hassle, but it really pays off with longer equipment life and consistently good results.

Another cool thing is that using a nanometer liposome extruder can actually cut down on production costs. Since it speeds up the process and reduces the need for extra steps, manufacturers can really scale up without sacrificing quality. Overall, jumping on this tech train not only helps companies stay competitive but also meets the rising demand for delivery systems that are more effective and easier for patients to use.

Liposome technology has really been gaining traction across different industries lately, and honestly, for good reason. It's super versatile and effective, whether we're talking about drugs, cosmetics, or even food products. In the pharma world, liposomes act like tiny delivery trucks for medications, helping them stay stable and get absorbed better by the body. The cool part? They can target specific cells, so the medicine does its job more precisely while cutting down on side effects. Plus, since they can carry both water-loving (hydrophilic) and oil-loving (hydrophobic) ingredients, there's a whole lot of room for new, innovative treatments that really make a difference in patient care.

On the beauty front, liposomes are pretty much game-changers when it comes to getting active ingredients like vitamins and antioxidants deep into the skin. By wrapping these ingredients up, skincare brands can create products that hydrate better and deliver benefits more effectively. It’s not just about function though – it feels luxurious too! And in the food industry, liposomes are used to trap flavors and nutrients, which helps keep products fresh longer and makes manufacturing a bit more efficient. All in all, the flexibility and potential of liposome technology keep driving innovation, making it an essential part of modern manufacturing processes.

| Benefit | Description | Application Area | Impact on Industry |

|---|---|---|---|

| Enhanced Drug Delivery | Improves the bioavailability of drugs. | Pharmaceuticals | Increases therapeutic efficacy. |

| Stability Improvement | Protects active ingredients from degradation. | Cosmetics | Extends product shelf life. |

| Targeted Delivery | Allows for selective targeting of cells. | Medical Research | Reduces side effects and enhances treatment outcomes. |

| Controlled Release | Regulates the release of active substances over time. | Nutraceuticals | Improves dosing accuracy. |

| Improved Solubility | Enhances the solubility of poorly water-soluble compounds. | Agriculture | Increases efficacy of active ingredients in formulations. |

| Customization | Facilitates customization for specific applications. | Food Industry | Supports the creation of tailored food products. |

| Sustainability | Reduces the use of preservatives and synthetic additives. | Personal Care | Promotes eco-friendly product formulations. |

These days, the manufacturing world is changing pretty fast — especially with all the new stuff happening in nanotech. Using a nanometer liposome extruder has become pretty much essential if you want to stay efficient and ahead of the game. It’s all about those advanced liposome extrusion techniques that let you craft smaller, more uniform liposomes. And trust me, these tiny particles are a big deal when it comes to effectively delivering drugs, especially in fields like pharma and biotech.

One of the coolest perks of using a nanometer liposome extruder is how it helps make your formulations more stable. Because the liposomes are more uniform in size, they’re less likely to clump together — which means the drug delivery works better overall. Plus, this kind of precision can boost bioavailability, so you might end up using lower doses with fewer side effects. That’s a huge plus, especially for things like mRNA vaccines and gene therapies.

**Quick tip:** To really get the most out of liposome extrusion, it’s super important to pick high-quality raw materials and keep your processing conditions just right. Don’t forget to regularly maintain and calibrate your equipment — it’ll save you headaches down the line and keep your production consistent. Also, investing a little in training your team can go a long way, helping everyone stay up-to-date with the latest tech and trends in the industry.

You know, as nanotechnology keeps zooming forward, we're really seeing some cool shifts in the manufacturing world, especially with all the new ways people are using nanometer liposome tech. I recently came across a report from Research and Markets, and it said that the global liposome market is expected to hit around $5.1 billion by 2025 — that's growing at about 5.3% annually since 2020. The big driver behind this? Liposomes are becoming pretty much essential in drug delivery, mainly because they do a fantastic job at boosting how well therapeutic agents get absorbed by the body.

On top of that, personalized medicine is really shaking things up — people want more tailored drug options now. Thanks to some advanced extruders, manufacturers can produce super uniform and stable nanometer-sized liposomes. That means they can scale up production more efficiently and improve how well drugs are encapsulated. A report from Allied Market Research interestingly points out that the injectable liposome sector is set to grow a lot, especially with new delivery methods opening doors to awesome treatments for cancer and other chronic illnesses. As manufacturers jump on these innovations, integrating nanometer liposome extruders is going to be a game-changer for the future of medicines and biomedical stuff alike.

: Liposome technology involves the use of liposomes as carriers for drugs, cosmetics, and food applications, enhancing bioavailability, stability, and targeted delivery, thereby improving effectiveness and outcomes.

In pharmaceuticals, liposomes enhance drug delivery by ensuring medications reach the right cells with minimal side effects, allowing for a broader range of therapeutic compounds to be utilized.

Liposomes enhance the penetration of active ingredients into the skin, encapsulating vitamins and antioxidants to improve hydration and the delivery of beneficial compounds, leading to more effective skincare products.

In the food sector, liposomes encapsulate flavors and nutrients, improving stability and extending the shelf life of products, which are crucial for modern food manufacturing.

A nanometer liposome extruder optimizes production efficiency by creating smaller, uniform liposomes, enhancing the stability and effectiveness of drug delivery systems, especially in pharmaceuticals and biotechnology.

Uniform liposomes are less prone to aggregation, leading to improved formulation stability, enhanced bioavailability, reduced dosages, and minimized side effects, which are critical factors in developing mRNA vaccines and gene therapies.

Manufacturers should select high-quality raw materials, maintain optimal processing conditions, and regularly calibrate extruders to prevent downtime and ensure consistent production quality.

Investing in staff training is crucial to help employees fully leverage advanced liposome technology and adapt to innovations, ensuring effective application in manufacturing processes.

The blog titled "7 Essential Benefits of Using a Nanometer Liposome Extruder in Modern Manufacturing" really dives into how nanometer liposomes are making waves across different industries. It kicks things off by breaking down the basics of liposome tech and explaining how the extrusion process actually works. The article then goes on to highlight seven major perks of using a Nanometer Liposome Extruder—for instance, how it boosts efficiency, keeps things consistent, and offers a lot of flexibility in creating top-quality formulations. It also takes a look at how these advanced extrusion techniques are being applied in various sectors, showing how they can really help streamline production.

Plus, the blog touches on where nanoliposome technology might be headed in the future, emphasizing all the cool innovations that could change the game. Since Cas Peter (Hangzhou) Nanotechnology Co., Ltd. is all about pushing the envelope with high-pressure homogenization, they’re pretty much set to meet the growing needs of industries working with nanotech and liposome-based products. Overall, it’s a solid read if you're curious about how this tech is shaping up and its potential to transform manufacturing processes.