In today's tough world of manufacturing, you really can't overstate how important efficiency is—especially in industries like food and beverages, pharmaceuticals, and cosmetics, where consistency and top-notch quality are everything. I mean, a recent industry report even says that the worldwide market for homogenizers could hit around USD 1.25 billion by 2027, growing at roughly 5.6% each year. So, tools like the Homogenizer Mixer Machine are pretty much essential—they help make products more uniform and streamline the whole production process.

Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are leading the way with high-pressure homogenization and microfluidic tech, offering innovative solutions tailored to different industry needs. By tapping into advanced nanotech, businesses can really ramp up their efficiency, cut down on downtime, and deliver better quality products. This guide’s gonna walk you through how adding a Homogenizer Mixer Machine to your setup can help boost your productivity and push your business forward.

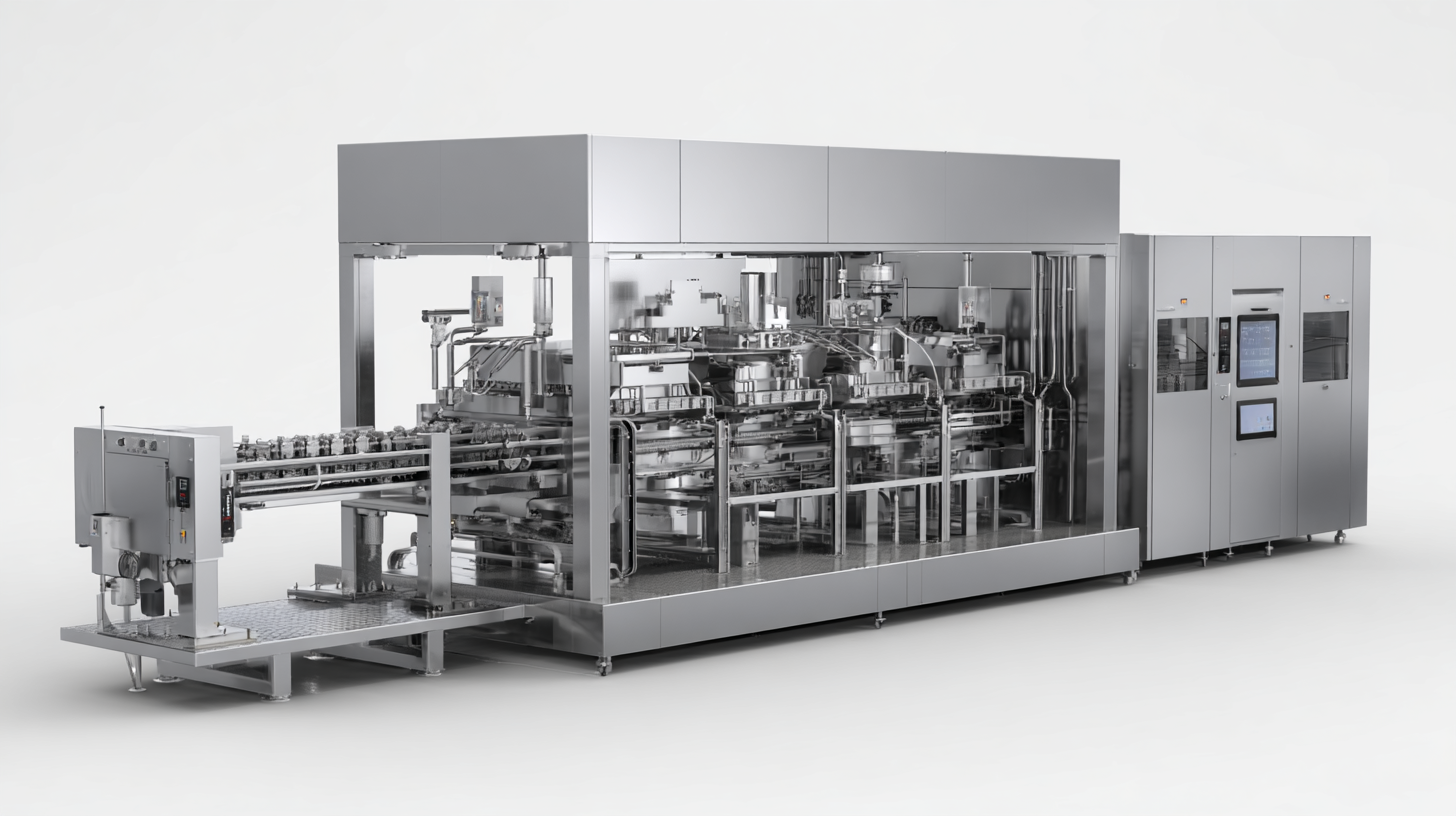

Homogenizer mixers are pretty much essential when it comes to boosting production speed across a bunch of different industries. Basically, they make sure that all the ingredients are mixed really uniformly, which helps cut down on waste and keeps the quality up. This consistent blending is especially important in fields like food and drinks, pharmaceuticals, and cosmetics — where sticking to strict standards isn’t just a nice-to-have, but actually a must. The precision these machines offer really helps prevent batch-to-batch differences, so manufacturers can confidently deliver reliable products and keep their customers happy.

Homogenizer mixers are pretty much essential when it comes to boosting production speed across a bunch of different industries. Basically, they make sure that all the ingredients are mixed really uniformly, which helps cut down on waste and keeps the quality up. This consistent blending is especially important in fields like food and drinks, pharmaceuticals, and cosmetics — where sticking to strict standards isn’t just a nice-to-have, but actually a must. The precision these machines offer really helps prevent batch-to-batch differences, so manufacturers can confidently deliver reliable products and keep their customers happy.

On top of that, bringing homogenizer mixers into the production line can make the whole mixing process way faster. You know how traditional mixing can sometimes take ages and involve a lot of manual effort? Yeah, those can create bottlenecks sometimes. But with homogenizers, the mixing is super quick and thorough, which means companies can push out more products without sacrificing quality. That kind of efficiency doesn’t just save money — it also gives businesses more room to adapt their schedules and respond quickly to market needs. If companies really understand how to use these machines right, they can streamline their processes and stay ahead in this constantly changing market. Honestly, it’s a game-changer for many brands out there.

When you're thinking about adding a homogenizer mixer to your production line, it’s pretty important to get a good grasp of the main features that make these machines efficient. A top-notch homogenizer should be built tough, able to handle heavy-duty use across different industries like food and drinks, pharma, and cosmetics. I was reading a recent market analysis by MarketsandMarkets, and it turns out the global market for these mixers is expected to hit around $1.2 billion by 2025. That just shows how much companies are craving better mixing solutions to keep their products uniform and consistent in quality.

Oh, and while you’re at it, look for mixers that come with adjustable speed controls and multiple mixing heads. These features let you tweak the machine to suit whatever product you're working on, which really helps improve efficiency and can cut down on production time. Research from Research and Markets also shows that machines with variable speeds can boost efficiency by about 20-30%. Pretty impressive, right?

Here’s a little tip: try to go for energy-efficient models whenever you can — they’ll probably save you a good chunk on energy bills over time, not to mention being better for the environment. Also, don’t forget about how easy it is to clean and maintain the machine. Picking a model that’s designed for quick disassembly can really save you from unnecessary downtime — trust me, it makes a difference when you're on a tight schedule.

This chart illustrates the efficiency improvement observed in production lines after the implementation of a high-quality homogenizer mixer machine. It compares the output in liters per hour across different production line setups.

In today's production lines, boosting workflow efficiency is pretty much essential if you want to stay competitive. One piece of equipment that’s really been making waves lately is the homogenizer mixer machine. It’s not just about speeding up the mixing process—it also ensures that the products are consistently high quality, which is a must in industries like food processing and pharma. I recently read a report, and turns out, companies that have adopted these advanced homogenization techniques have seen around a 20% boost in overall productivity. That really highlights why adding this kind of machinery to your line isn’t just a good idea — it’s pretty much necessary.

Plus, there’s been some serious progress on the tech side of things. Modern homogenizer mixers are way more energy-efficient than older models, sometimes cutting energy use by up to 30%. This not only helps cut down costs but also makes production a bit more environmentally friendly. For example, companies working with material dispersion or running continuous online processes have noticed cycle times dropping dramatically. That means they can get products out quicker without sacrificing quality. With demand for top-notch, consistent products rising, going for a homogenizer mixer isn’t just smart — it’s pretty much vital for keeping things running smoothly and efficiently.

Taking care of your homogenizer mixer is super important if you want it to keep running smoothly and last a good long time in your production setup. The first thing you definitely don’t wanna skip is cleaning — seriously, it’s key. After each use, make sure to take apart the parts and give them a proper scrub with the right cleaning agents. Just a heads-up: always check the manufacturer’s instructions so you don’t accidentally damage anything inside the machine. Trust me, better safe than sorry!

And don’t forget about regular inspections. It’s a good idea to keep an eye out for signs of wear and tear like rust, frayed belts, or weird noises coming from the machine — those could be clues something’s not quite right. Lubricating the moving parts is another step that’s worth doing; it helps cut down on friction and prolongs the life of your equipment. Setting up a maintenance schedule might seem like a hassle at first, but honestly, it pays off. It keeps your machine in tip-top shape and helps avoid costly breakdowns, so your production line can keep chugging along without a hitch.

| Maintenance Tip | Frequency | Effects of Neglect | Recommended Action |

|---|---|---|---|

| Clean Mixing Chamber | After each use | Contamination and flavor transfer | Use hot water and a suitable detergent |

| Check Seals and Gaskets | Monthly | Leaks and loss of efficiency | Replace damaged parts immediately |

| Lubricate Moving Parts | Quarterly | Increased wear and tear | Use manufacturer-recommended lubricant |

| Inspect Electrical Components | Every 6 months | Risk of unplanned downtime | Ensure connections are tight and replace worn parts |

| Calibrate Mixing Speed | Annually | Inconsistent product quality | Follow calibration procedures as per manual |

When you're working with a homogenizer mixer on a production line, it's super important to keep an eye out for issues that might mess with both efficiency and the quality of your product. Things like not getting enough homogenization done, the viscosity being way off, or the machinery just wearing down over time – these can all cause headaches. I read somewhere, from the International Society of Homogenization, that if you don’t set things up right, you could lose up to 30% of your processing efficiency. Yikes! To avoid that, it’s really worth doing regular calibration and maintenance on your equipment. Checking the viscosity and pressure levels regularly can make a big difference in making sure everything runs smoothly and you’re not overloading the machine.

Another common issue that comes up is cavitation – it can really mess with product quality and even damage the machine. The American Institute of Chemical Engineers mentioned that if you don’t keep an eye on cavitation, it could cut your production output by up to 25%. The trick is implementing real-time monitoring systems, so you can tweak things on the fly and keep cavitation in check. Also, investing in good operator training and sticking to best practices will go a long way toward keeping the homogenizer running like a champ. All in all, these steps help ensure your process is smooth sailing and that your final products stay top-notch.

Lately, a lot of industries have been jumping on the bandwagon with homogenizer mixers to make their production lines run a lot smoother. Take a dairy company, for example—they were having a tough time keeping their product texture consistent, which was really frustrating their customers. Once they started using a homogenizer mixer, everything changed — their milk and dairy products became way more uniform, which made a big difference. Not only did the quality improve, but they also managed to cut down their production time by about 20%. That meant they could keep up with demand a lot easier and keep their customers happy.

And then there’s the cosmetics world, which has its own stories. A skincare brand was struggling with ingredients not staying mixed properly in their creams and lotions. After they introduced a homogenizer mixer into their process, they saw a huge boost in how well everything emulsified. The end result? A cream that’s way smoother, way more appealing to customers, and they even managed to introduce new formulas faster. It really transformed their product lineup and helped them grow their sales — pretty impressive, right?

: The primary function of a homogenizer mixer machine is to ensure a uniform mixture of ingredients, eliminating inconsistencies that can lead to waste and a reduction in product quality.

Homogenizer mixer machines are particularly important in the food and beverage, pharmaceuticals, and cosmetics industries, where product standards are stringent.

They speed up the mixing process, minimize batch variances, and enable manufacturers to increase output without compromising quality, leading to overall cost savings and greater flexibility in production schedules.

Companies utilizing advanced homogenization techniques have reported a 20% increase in overall productivity.

Modern machines can reduce energy usage by up to 30% compared to older models, contributing to lower operational costs and more sustainable production practices.

Companies experience improved workflow efficiency, reduced cycle times, faster turnaround, and the ability to respond more quickly to market demands.

As the demand for high-quality and consistent products rises, investing in homogenizer mixer machines becomes essential for maintaining efficient production workflows and staying competitive.