When you think about modern nanotechnology these days, having a reliable lab homogenizer is a must. More and more industries are jumping into high-pressure and microfluidic homogenization, so it’s really important to understand what makes these devices tick if you want things to run smoothly. Recent industry reports are saying that the global market for homogenizers could hit around $1.75 billion by 2027 — which isn’t too surprising given how crucial they’ve become in pharma, food, beverage, and cosmetic industries.

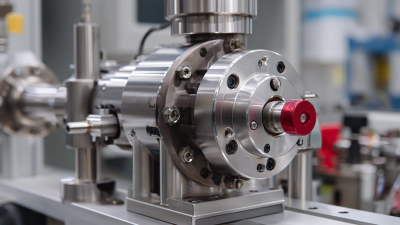

CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is really leading the charge here, focusing on creating and selling high-pressure and microfluidic homogenizers that fit a bunch of different industrial needs. By staying at the cutting edge of nanotech innovations, CAS PETER is all about making homogenization more efficient — which means better quality and consistency for a wide range of products. It’s an exciting time for this tech, and these companies are making it happen!

When you're choosing a lab homogenizer, it's pretty important to get a good sense of the key features that will actually make your work easier and give you the best results. One of the first things to look into is the speed range. Having a wider range means you can handle all kinds of samples, from gentle cell suspensions to tougher tissue bits. Make sure the homogenizer has adjustable speeds, too — that way, you can really tailor the process depending on what you're working on.

Oh, and don't forget to check out the motor's power. A strong motor helps ensure your samples are emulsified and blended consistently, which is super important if you want reproducible results. The design of the device also matters; an ergonomic setup not only feels better in your hand but can also improve your efficiency, especially during long sessions.

When you're working on optimizing lab homogenizers, understanding how crucial RPM (that’s revolutions per minute) and shear rate are really makes a difference. RPM affects how much energy you're putting into your samples during processing, and this directly impacts how well everything gets mixed and how good your final product turns out. Usually, cranking up the RPM improves mixing and dispersion, but you’ve gotta be careful and keep an eye on the shear rate too—too much can actually harm sensitive samples. The key is to find that sweet spot with a good-quality homogenizer, one that lets you control these settings precisely. That way, you get effective processing without risking damage to your samples.

At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about high pressure homogenizers and microfluidizers tailored to different industry needs. Our machines are adjustable, so you can set the RPM just right and optimize shear rates for the best results—especially in nanotech stuff. Knowing how these factors work together helps researchers and manufacturers get top-notch results, boosting product quality and performance. It’s not just about making things run smoothly; it’s about tapping into advanced tech to push innovation forward.

When you're choosing a lab homogenizer, it's really important to get a good handle on the

volume capacity—this basically means how much sample it can handle comfortably

without messing up your results. You want to pick a homogenizer that matches the size of your samples; if it's too big, you might not get the best

mixing, and if it's too small, your workflow could slow down because you’re constantly switching samples. It’s all about finding that

sweet spot.

Also, keep in mind that the volume capacity can affect the whole process. Different types of samples need different setups—say, a really thick, viscous sample might require a larger capacity to make sure everything gets mixed properly and the shear forces do their thing. Plus, consistency is key—especially in sensitive tests where even tiny differences can throw off your results. If you pay attention to volume capacity along with all the other features, you'll find that your workflow runs smoother, and you get reliable, high-quality results every time.

When you're working on lab homogenization, choosing the right materials can really make a difference in how effective and high-quality your samples turn out. Usually, people go for stainless steel or glass beads — and each has its own perks. Stainless steel beads are pretty tough and resistant to breaking, so they’re great for those stubborn samples that need a lot of grinding. They can handle high-impact, high-energy use without fuss, giving you steady performance no matter what.

On the flip side, glass beads have their own set of benefits, especially if you're worried about contamination. They're non-reactive, which means they don’t add metallic ions into your samples—super important if you're working with stuff like pharmaceuticals or biochemistry. Plus, glass beads are easier to clean and sterilize, giving you a bit more peace of mind when it comes to avoiding cross-contamination. At the end of the day, your choice really comes down to what your specific lab process needs, what kind of samples you’re dealing with, and what results you’re aiming for.

When you're picking out a lab homogenizer, energy consumption should really be at the top of your mind—because, let's be honest, it’s a big factor in your lab’s overall running costs. A good, efficient homogenizer doesn’t just do a better job of getting uniform particles; it also keeps energy waste to a minimum. If you go for a model with adjustable speeds and smart power settings, you can actually tweak how much energy it uses based on what you’re working on. That could mean some pretty nice savings in the long run.

Plus, the upfront cost of an energy-efficient model can often be balanced out by lower utility bills later on. Many of the newer homogenizers come with high-tech features that keep track of how much energy they’re using—so you can see if there are ways to cut back even more. Regularly checking these energy stats really helps labs make smarter choices about upgrading equipment or changing how they operate, which ends up boosting productivity and saving money. Focusing on energy efficiency when you’re choosing equipment isn’t just good for the planet, it’s also a smart move for your bottom line.

When you're shopping for a lab homogenizer, it's really important to pay attention to standard compliance and certification. Trust me, reliable homogenization is key if you’re after consistent results—whether you're working in pharma, food processing, or biotech. A report from ISO mentioned that sticking to standards like ISO 9001 can make a huge difference in product quality and safety, making sure your equipment performs as it should.

Pro tip: Always look for those certification labels on your homogenizer. Equipment that ticks these boxes tends to give more reliable results and keeps things safe. Certifications like CE, FDA, and GMP are especially important if you're working in tightly regulated fields—they're kinda like a seal of trust that the machine will perform well.

Plus, certified homogenizers go through pretty tough testing to check their efficiency and safety features. According to a study by ANSI, using compliant devices actually reduces the risk of cross-contamination, which is a big deal in labs. So, making sure your homogenizer has these certifications not only protects your research’s integrity but also boosts credibility when you share your results.

Another tip: Don’t hesitate to ask manufacturers about their compliance with these standards. Request to see documentation, too—that way you know you’re choosing equipment that’s durable and fits within your specific regulatory needs.

: A key feature to consider is the homogenizer's speed range, which allows for versatility in processing various samples.

A powerful motor ensures consistent emulsification and blending, which is essential for reproducible results.

Common options include rotor-stator setups for high shear mixing and probe-based systems for targeted homogenization; the type can significantly impact sample integrity.

RPM impacts the energy input during processing, influencing homogenization efficiency, while shear rate must be balanced to avoid damaging sensitive samples.

Stainless steel beads are durable and resist breakage, making them ideal for tough materials requiring extensive homogenization.

Glass beads are non-reactive, do not introduce metallic ions, and are easier to clean and sterilize, making them better for contamination-sensitive applications.

An ergonomic design enhances user comfort and promotes efficiency, especially during extended use.

A user-friendly design saves time and reduces the risk of contamination between experiments, which is crucial for maintaining sample integrity.

Adjustable RPM settings allow for precise control over mixing and dispersion, facilitating optimal outcomes based on sample requirements.

Compatibility with different sample materials ensures that the homogenizer can be effectively used across various experiments without compromising results.

When you're on the hunt for a Lab Homogenizer, it’s super important to keep a few key features in mind, because they really affect how well it works. Things like RPM and shear rate are big deals—they basically determine how efficiently your samples get processed. And don’t forget about volume capacity; knowing this helps you pick a machine that can handle different sample sizes without any hassle. The material of the beads, whether stainless steel or glass, also matters quite a bit—impacting not just durability but how well the homogenization actually works.

Oh, and be sure to check out the energy consumption ratings too—more efficient models could save you a decent chunk of money in the long run. Finally, making sure your lab homogenizer is compliant with relevant standards and certifications is a must for safety and reliability. At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re experts in high-pressure homogenizers and microfluidizers. We’re dedicated to providing innovative nanotech solutions that fit a wide range of needs across different industries."