Lately, there's been a huge surge in demand for advanced mixing and homogenization tech across all sorts of industries. I guess it’s all about getting better product quality and performance, right? According to a report by MarketsandMarkets, the global market for homogenizers is expected to hit around USD 1.07 billion by 2025. And interestingly, there’s a big push towards more innovative solutions like the Multimix Homogenizer. This new gadget is pretty impressive — it’s incredibly efficient at making sure particles are evenly sized and it really helps boost stability in emulsions and suspensions.

Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re proud to be at the forefront, providing high-pressure homogenizers and microfluidizers. Our goal? Keep pushing the boundaries of nanotech, no matter if it’s in pharma, food, or drinks. In this blog, I want to dive into how the Multimix Homogenizer is changing the game, touching on its wide-ranging applications and what exciting things it might bring in the future.

These days, the pharma world is really starting to see how important multimix homogenizers are for making better, more efficient products. You know, these high-tech mixers are actually pretty vital when it comes to formulating different kinds of medicines—especially in the development of bio-pharmaceuticals and vaccines. A recent market report from Grand View Research mentions that by 2027, the global market for pharmaceutical processing equipment could hit nearly 30 billion dollars, with a big chunk of that growth fueled by cool innovations in homogenization tech.

One hot trend right now? Using multimix homogenizers to produce nanoemulsions and liposomal formulations. Why does that matter? Well, these techniques boost how well drugs dissolve and get into the body—super important since effective delivery systems can make or break a drug’s success. There’s even research published in the *International Journal of Nanomedicine* showing that nanotech-based formulations can really ramp up therapeutic effects. As the pharma industry faces new hurdles, it looks like these homogenizers are gonna be key players in developing the medicine of the future.

| Industry | Application | Benefits | Emerging Trends |

|---|---|---|---|

| Pharmaceuticals | Formulation of emulsions | Improved stability and bioavailability | Nanotechnology integration |

| Cosmetics | Creation of lotions and creams | Enhanced texture and performance | Sustainable ingredient sourcing |

| Food & Beverage | Production of sauces and dressings | Consistent quality and taste | Clean label products |

| Chemical | Manufacturing of adhesives | Reduced processing time | Smart manufacturing technologies |

| Biotechnology | Cell lysis and homogenization | Higher yield of products | Personalized medicine approaches |

Using Multimix Homogenizers in food processing has really changed the game for manufacturers. It’s no secret that these little machines help boost efficiency and keep quality in check. I came across a report by Research and Markets that says the global market for food emulsifiers might hit around $4.5 billion by 2024 — and a lot of that growth comes from innovations in processing tech. Multimix Homogenizers are key players here, thanks to their ability to create stable emulsions and finely reduce particle sizes. Their powerful mixing not only helps evenly distribute ingredients but also makes the final product taste better and have a better texture, which really makes customers happy.

What’s even cooler is that using these homogenizers can save a bunch of time and energy during production. There's a study in the Journal of Food Engineering that shows high-shear homogenizers can cut processing time by up to 30%. That’s a huge deal because it means lower costs and getting products to market faster. Plus, they’re pretty great when it comes to safety and hygiene. They make cleaning and maintenance way easier, which is perfect as more brands are aiming for clean-label products. Overall, it’s clear that manufacturers are leaning on Multimix Homogenizers not just to meet current standards but to make their products even better.

In the competitive world of cosmetics, getting the texture and stability just right is pretty much everything. That’s where multimix homogenizers really come in—they’re game-changers for manufacturers trying to whip up smooth, uniform emulsions that make consumers go wow. These machines are pretty amazing at blending ingredients efficiently, which means your creams, lotions, and serums stay consistent in quality and perform well over time. Plus, the level of precision they offer opens up a whole bunch of formulation possibilities—catering to different skin types and personal preferences.

**Tip 1:** When working on emulsions, pay attention to the order in which you add ingredients. Usually, it’s best to start with the oil phase, then slowly incorporate the water phase while using the homogenizer. It helps create that nice, smooth texture you’re aiming for.

Another thing to keep in mind with multimix homogenizers is temperature control during mixing. Keeping the right temperatures helps protect sensitive ingredients—like essential oils and active ingredients—meaning your final product will be more effective and stable.

**Tip 2:** For better stability, run tests under different environmental conditions. That way, you can be confident your formulation will stay effective and appealing to customers over time.

This chart illustrates the effects of using multimix homogenizers on the texture and stability of various cosmetic products. The data shows the improvement in stability percentages before and after the use of homogenizers in formulations such as creams, lotions, and serums.

You know, when it comes to chemical manufacturing, using Multimix Homogenizers is really gaining traction, especially in the whole sustainability scene. I came across a report from MarketsandMarkets that says the global market for homogenizers is expected to hit around $1.46 billion by 2025. That’s pretty impressive, and it makes sense given how there's a growing push for energy-efficient, eco-friendly production methods these days. These Multimix Homogenizers are pretty amazing—they do a great job in breaking down particles more finely and making products more stable. That means less waste and lower energy use, which is a win-win for everyone.

At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about high-pressure homogenization and microfluidization, and honestly, these fit perfectly with the whole sustainability vibe. Our tech helps companies create better emulsions and dispersions—think of it as reducing the need for harmful solvents and too many additives. It’s a small change that really adds up in lowering the environmental impact. Plus, bringing Multimix Homogenizers into the mix isn’t just about making better products; it also helps companies stay in line with stricter regulations on industrial emissions. Basically, they’re making a real difference in pushing the chemical industry toward a greener future.

And here’s a nice bonus—research shows that fine-tuning homogenization can cut energy costs by up to 30%. So, as industries face tighter environmental rules, investing in these advanced homogenizers isn’t just trendy—it’s actually a smart move for sustainable growth.

You know, the biotech world is really shaking things up these days with all these new multimix homogenization techs coming into play. They're actually making a big difference by improving how consistent and stable products turn out—stuff like medicines and food products really benefit from this. I saw a report from Grand View Research that says the global market for homogenizers could hit around USD 2.3 billion by 2025. That's mainly because there's so much growing demand for better emulsions and suspensions in biotech fields.

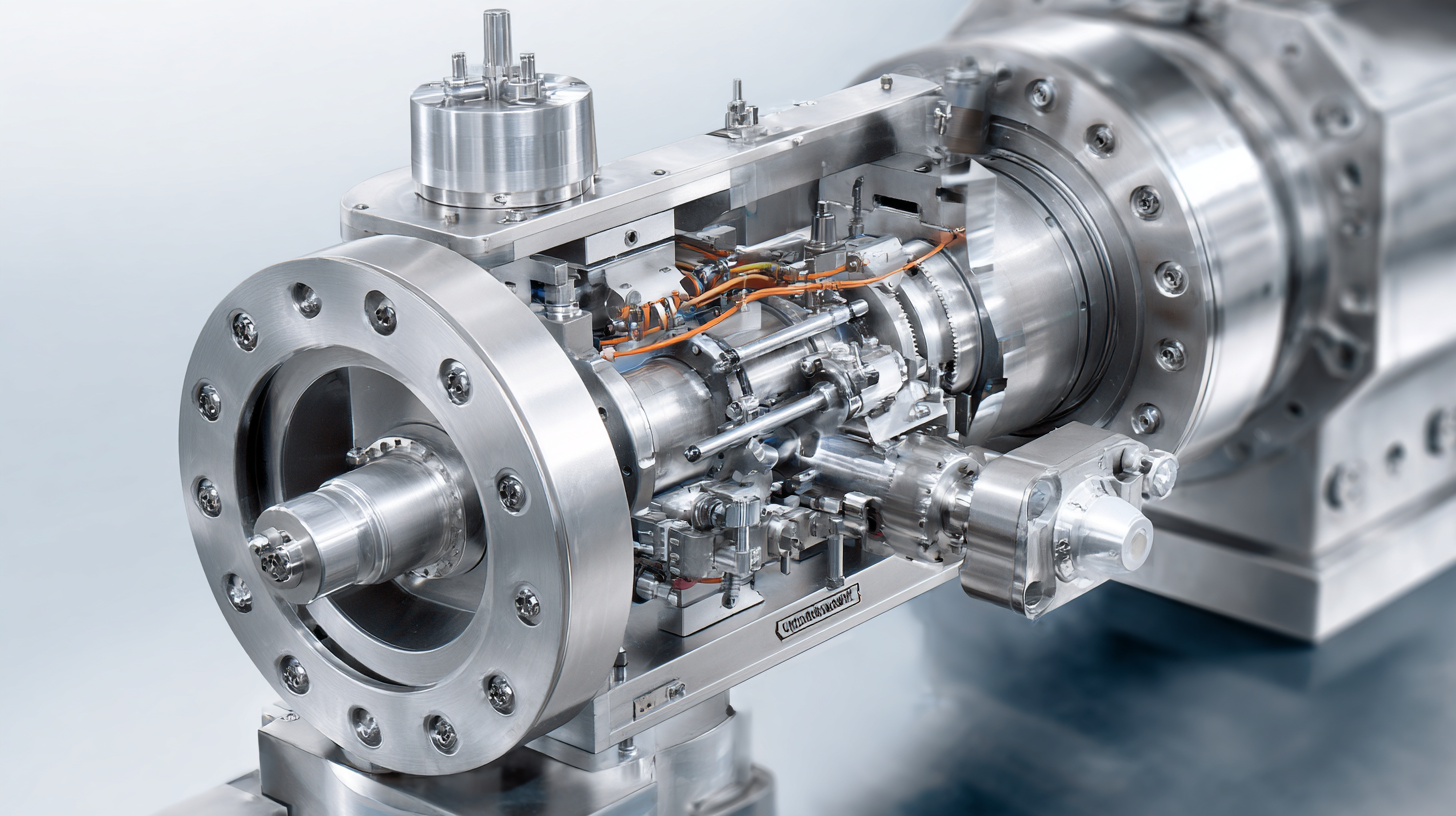

Now, these multimix homogenizers are pretty impressive. They’re built with some unique designs and features that allow for super efficient mixing and finer particle reduction. This stuff is pretty critical when you're talking about making vaccines or biologic drugs—getting a uniform mix can really make or break how well they work. Compared to older, traditional mixers, these multimix gizmos can boost processing speed by about 30% and improve product stability by roughly 15%. Honestly, they’ve become pretty much essential tools for anyone into modern bioprocessing.

A quick tip if you're thinking about picking one: pay attention to how scalable it is and how easy it’s to clean. Making sure it can handle different viscosities will save you a lot of hassle and resources down the road. Also, if you can find one with automation options, that’s a game-changer—it can really help speed things up and make your production smoother.

Looking ahead, it’s pretty exciting to see how multimix homogenizers are shaping up across different industries. The demand for top-notch emulsions and more efficient mixing processes is really driving things forward. I recently came across a market research report that says the global market for homogenizers might hit around $1.5 billion by 2027—pretty impressive, right? And it’s growing at roughly 5.6% annually since 2020. This surge is mainly because these machines are becoming a go-to for sectors like food and drinks, pharmaceuticals, and cosmetics—where consistency and quality are totally non-negotiable.

In the food world, for instance, these homogenizers are really helping out with making sauces, dressings, and dairy stuff smoother and more uniform. The market for food emulsifiers alone could reach about $5.6 billion by 2025—that’s a clear sign of how closely food processing is tied to this technology. On the pharma side, these machines are crucial for creating stable emulsions and effective formulations. The pharma emulsifiers market is expected to grow to around $1.8 billion by 2024, which makes sense given how much more focus there’s now on making medications more bioavailable and easier for patients to take.

Long story short, as industries keep evolving, these homogenizers will need to keep up with new demands. Luckily, with all the ongoing tech advancements, they’re only going to become more important in making products better and streamlining production. It’s pretty clear that their role in improving quality and efficiency isn’t going anywhere anytime soon—with big things expected in the future.

: Multimix homogenizers are advanced mixing devices that enhance product quality and efficiency in pharmaceutical formulations, particularly for bio-pharmaceuticals and vaccines.

These homogenizers facilitate improved drug solubility and bioavailability, which are critical for effective drug delivery systems.

The global pharmaceutical processing equipment market is projected to reach USD 29.96 billion by 2027, largely driven by innovations in homogenization technologies.

They optimize ingredient dispersal, create stable emulsions, enhance texture and taste, and ensure improved quality control in food products.

High-shear homogenizers can cut processing time by up to 30%, leading to lower operational costs and higher throughput.

The global food emulsifiers market is projected to reach $4.5 billion by 2024, driven by advancements in processing technology.

They facilitate better cleaning and maintenance protocols, ensuring strict adherence to hygiene and safety standards.

The increasing demand for clean-label products and the need for enhanced quality control are driving the reliance on multimix homogenizers.

By improving the texture and taste of food products, they increase consumer satisfaction and support manufacturers in meeting consumer demands.

As the pharmaceutical sector adapts to new challenges, multimix homogenizers are expected to play an integral role in the innovation of drug delivery systems and the development of advanced therapeutics.

The blog titled 'Innovative Applications of Multimix Homogenizer in Various Industries' dives into how these machines are truly changing the game across different fields. For example, in pharma, they're really leveraging new trends to make drug formulation and delivery more efficient and effective—it's pretty impressive. When it comes to food processing, Multimix Homogenizers are actually helping improve quality control, ensuring products have that consistent texture we expect, and boosting overall integrity.

Plus, the cosmetics world is getting a boost too, using these tools to achieve the perfect texture and stability in their formulations. Even in chemicals, companies are seeing benefits like less waste and lower energy use, which is a win for the environment. And let’s not forget biotech—these innovations are totally reshaping that landscape as well. Looking ahead, it’s pretty clear that these versatile machines still have a lot of room to grow and make an impact across tons of industries. As a leader in high-pressure homogenization and microfluidization, CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is all in on pushing these advancements forward, offering the latest nanotech solutions to meet all kinds of industrial needs.