A Homogenizer Mixer is one of those essential pieces of kit that you’ll find used across all sorts of industries — from food manufacturing and pharma to cosmetics. It’s a pretty versatile tool that plays a crucial role in creating smooth, uniform mixtures. Basically, it makes sure all the ingredients are blended together just right, giving you that perfect consistency and stability. By breaking down bigger particles and spreading them evenly throughout the mix, it boosts the overall quality of the products, improves their texture, and even helps them last longer on the shelf.

Using a Homogenizer Mixer involves applying some serious mechanical shear forces to the materials inside. As these forces do their thing, they break apart larger clumps and lumps, making the final product much more uniform. This process doesn’t just improve how the product looks and feels — it also makes it easier to emulsify liquids that normally don’t mix well, which is a game-changer in production lines where consistency really counts.

In this article, I’ll take a closer look at how these mixers work, the different types you can find, what they’re used for, and the tech behind their operation. Getting a handle on how these mixers function can help businesses figure out if they should add one to their manufacturing setup — leading to better products and happier customers in the long run.

A homogenizer mixer is an advanced piece of equipment used in various industries to achieve a uniform mixture of substances. Essentially, it works by applying intense mechanical forces, such as shear and impact, to break down particles and disperse them evenly throughout a liquid medium. This technology is critical in sectors like food and beverage, pharmaceuticals, and cosmetics, where consistency and texture are paramount. According to a report by MarketsandMarkets, the global homogenizer market is projected to grow from approximately $1.8 billion in 2022 to $2.5 billion by 2027, indicating an increasing reliance on these devices for industrial applications.

In practical terms, a homogenizer mixer can significantly enhance the stability and quality of products. For instance, in the food industry, it is not uncommon for emulsified products to experience separation over time; homogenizers effectively prevent this by maintaining a stable blend of oil and water phases. A study published by the International Journal of Food Science found that products processed with homogenizers had an average shelf life increase of 20% compared to those that were not homogenized. This increase not only improves product longevity but also ensures a higher standard of quality for consumers, driving demand in an increasingly competitive market.

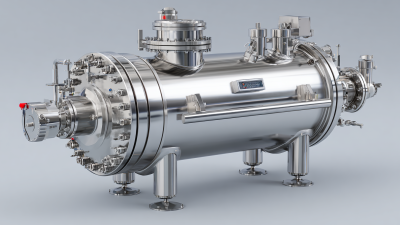

The history of homogenizer mixers dates back to the late 19th century when the need for uniform consistency in products became increasingly important in the food and beverage industry. Early versions of homogenizers were simple devices that relied on manual processes, but as industrialization progressed, so did the technology. By the mid-20th century, advancements in engineering allowed for the development of high-pressure homogenizers that could achieve finer particle sizes and improved stability in emulsions. This transformation dramatically changed various sectors, from dairy processing to pharmaceuticals, enabling manufacturers to deliver products with enhanced quality and shelf life.

As homogenizer mixers evolved, they began incorporating innovative designs to cater to diverse applications. These mixers not only improved the texture of food products but also played a critical role in developing homogenous mixtures in cosmetics and adhesives. The ongoing research and development in this field continue to enhance their efficiency and effectiveness, making these machines indispensable in many industries.

Tips: When selecting a homogenizer mixer, consider the specific application to ensure optimal performance. Additionally, regular maintenance is crucial to prolong the lifespan of the equipment and maintain product quality. Always consult with experts to choose the right size and type for your production needs, as this can greatly affect the efficiency of your processes.

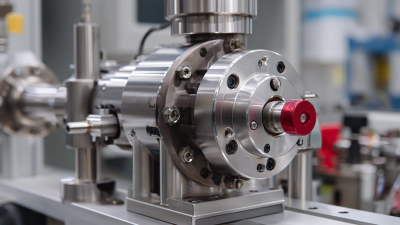

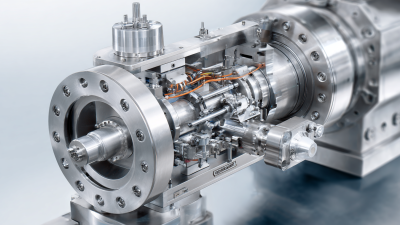

A homogenizer mixer is an essential piece of equipment primarily used in food, pharmaceutical, and cosmetic industries to achieve uniform consistency in products. The key components of a homogenizer mixer include the rotor, stator, and the shear gap. The rotor spins at high speeds, creating a powerful vortex that draws the materials into its flow. This is complemented by the stator, which houses the rotor and creates a controlled environment where the materials are subjected to intense mechanical forces. The shear gap, the space between the rotor and stator, plays a critical role in determining the final particle size and distribution of the mixture, impacting the overall homogeneity of the product.

Recent industry reports indicate that these mixers not only enhance product stability but also extend shelf life, which is crucial in the competitive food and beverage sector, projected to reach a valuation of approximately $4 trillion by 2025. The efficiency of homogenizer mixers is further evidenced by studies showing that products treated with high-shear mixing techniques exhibit superior qualities, including improved texture and mouthfeel, meeting the increasing consumer demand for premium products.

Moreover, advancements in homogenization technology have led to the development of energy-efficient models, which can result in up to 30% energy savings compared to traditional mixers, aligning with the global push for sustainability in manufacturing processes.

A homogenizer mixer is a crucial piece of equipment in various industries, including food processing, pharmaceuticals, and cosmetics. Its primary function is to create a uniform mixture by breaking down particles in a substance. The process involves using high pressures or mechanical forces to ensure that all components are evenly distributed, resulting in a consistent texture and improved stability.

The mechanism of a homogenizer mixer typically involves forcing a mixture through narrow spaces or valves, which creates turbulence and shear forces. This action disrupts larger particles and promotes the merging of smaller ones. The outcome is a smooth emulsion or suspension, enhancing the quality and shelf life of the final product. Additionally, homogenization can improve the bioavailability of ingredients in certain formulations, making it an essential step in product development.

Tips: When using a homogenizer mixer, ensure that the materials are pre-mixed to reduce the overall load on the equipment. This practice not only enhances efficiency but also minimizes wear and tear on the machine. Additionally, monitor the temperature of the mixture, as excess heat can affect the properties of sensitive ingredients. Regular maintenance and cleaning of the homogenizer are crucial to prevent contamination and ensure consistent performance.

Homogenizer mixers are versatile tools widely utilized across various industries for their ability to achieve consistent and uniform product textures. In the food industry, they are essential for creating emulsions such as sauces, dressings, and dairy products. By effectively dispersing fat droplets within a liquid, homogenizer mixers enhance the stability and mouthfeel of these products, ensuring that the ingredients remain evenly mixed over time. Their role is crucial in manufacturing ice cream, where they help achieve a smooth texture by breaking down fat globules, thus preventing ice crystal formation.

In the pharmaceutical and cosmetic sectors, homogenizer mixers are invaluable as well. They facilitate the production of creams, lotions, and serums by ensuring that active ingredients are finely blended and evenly distributed. This uniformity not only affects the efficacy of the products but also plays a significant role in their aesthetic appeal. In the chemical industry, homogenizers are employed to mix specialized materials, ensuring that pigments, additives, or reactive agents are uniformly integrated into formulations. This capability enhances product quality across a wide range of applications, highlighting the critical role of homogenizer mixers in modern manufacturing processes.

Homogenizer mixers offer numerous advantages across various industries, particularly in food processing, pharmaceuticals, and cosmetics. One of the primary benefits is the ability to achieve a uniform consistency in products. This ensures that ingredients are evenly distributed, resulting in products that are not only visually appealing but also of high quality. For instance, in the food industry, a homogenizer mixer can break down fat molecules, creating smoother textures in items like sauces, dressings, and ice creams. This uniformity enhances product stability, allowing for longer shelf life and improved consumer acceptance.

Another significant advantage of using a homogenizer mixer is the ability to enhance the flavor and nutritional profile of products. By thoroughly mixing ingredients at a molecular level, these mixers can improve the solubility of vitamins and minerals, ensuring that they are effectively integrated into the final product. This is particularly beneficial in the production of dairy products and beverages, where flavor infusion and nutrient distribution are critical. Additionally, homogenizer mixers minimize the need for emulsifiers and stabilizers, making products healthier and often more appealing to health-conscious consumers.

Maintaining a homogenizer mixer is crucial to ensure its efficient operation and longevity. Regular maintenance can prevent common issues that may arise during intensive use, such as wear on the rotor-stator assembly or contamination of the sample. According to industry reports, proper upkeep can extend the lifespan of a homogenizer by up to 30%. Scheduled cleaning is vital; using appropriate detergents and sanitizing agents helps to avoid cross-contamination, especially in food and pharmaceutical applications where hygiene is paramount.

In addition to regular cleaning, it is essential to monitor the wear and tear of various components. Organizations operating homogenizers should perform routine inspections on seals, gaskets, and bearings, with research indicating that up to 40% of homogenizer failures are attributed to neglected parts. Utilizing a maintenance log can aid in tracking the operational hours and maintenance activities. Furthermore, training personnel on the correct operating procedures can significantly reduce the risk of damage and increase efficiency, contributing to an estimated 15% reduction in downtime for facilities that implement such training.

| Feature | Description | Maintenance Tip |

|---|---|---|

| Type | Mechanical homogenizer | Regularly check the coupling for wear |

| Applications | Food, pharmaceuticals, cosmetics | Clean after each use to prevent contamination |

| Operating Principle | Shear and turbulence to mix substances | Ensure proper alignment of mixing elements |

| Speed Settings | Variable speeds for different viscosities | Adjust speed based on product requirements |

| Common Issues | Overheating, insufficient mixing | Monitor temperatures and adjust runtime |

| Cleaning | Use appropriate cleaning solutions | Disassemble and sanitize all parts regularly |

: A homogenizer mixer is primarily used to achieve uniform consistency in products across food, pharmaceutical, and cosmetic industries, ensuring even distribution of ingredients and enhancing overall product quality.

The technology of homogenizer mixers has evolved from simple manual devices in the late 19th century to high-pressure homogenizers in the mid-20th century, which can achieve finer particle sizes and improved emulsion stability.

The key components of a homogenizer mixer include the rotor, stator, and the shear gap. The rotor creates a vortex that draws materials into flow, while the stator provides a controlled environment for mixing under mechanical forces.

Homogenizer mixers provide uniform consistency, enhance texture, improve flavor and nutritional profiles, and extend shelf life, making them essential for food product quality and consumer acceptance.

By achieving uniform consistency and breaking down ingredients at a molecular level, homogenizer mixers improve product stability, which allows for longer shelf life and reduces the need for additional emulsifiers and stabilizers.

Homogenizer mixers are widely used in food processing, pharmaceuticals, and cosmetics industries due to their ability to create homogenous mixtures and improve product quality.

Recent advancements in homogenization technology have resulted in energy-efficient models that can achieve up to 30% energy savings compared to traditional mixers, contributing to sustainability efforts in manufacturing.

Regular maintenance is crucial to prolong the lifespan of the equipment and ensure optimal performance, thereby maintaining product quality and overall efficiency in production processes.

By creating higher quality products with improved textures and flavors, homogenizer mixers align with increasing consumer demand for premium products, enhancing overall product appeal in the market.

Homogenizer mixers improve the solubility and integration of vitamins and minerals in the final product, making them particularly beneficial in the production of dairy products and beverages.

A Homogenizer Mixer is a specialized device designed for blending and emulsifying various substances to achieve a uniform consistency. It has evolved significantly over the years, with advancements in technology enhancing its efficiency and reliability. The key components include the homogenizing chamber, rotor, and stator, which work together to create shear forces that break down particles and distribute them evenly throughout the mixture.

Homogenizer Mixers are widely used across multiple industries such as food and beverage, pharmaceuticals, and cosmetics. They provide numerous advantages, including improved texture and shelf life of products. Proper maintenance and care are essential to ensure optimal performance and longevity of the equipment, which plays a critical role in the production process. Overall, the Homogenizer Mixer proves to be an invaluable tool for achieving high-quality emulsified and blended products.