These days, in the world of industrial processing, the Homogenizer Machine has become a pretty essential piece of equipment across all kinds of industries. Honestly, it really helps in making sure products are consistent and uniform – which is super important, especially in food and beverage, pharma, and chemicals. Basically, what a Homogenizer does is break down particles, mix ingredients, and emulsify solutions, so the final product lives up to the high standards customers and regulators expect.

The way it works is pretty clever—using high-pressure systems or rotor-stator setups to evenly distribute particles throughout a liquid. This isn’t just about improving the texture and flavor of food; it also boosts the stability and effectiveness of medicines and other formulations. As industries continue pushing for better quality and innovation, getting a good grip on how these machines operate and their benefits is more important than ever. It’s really opening doors to smarter product development and better processing techniques.

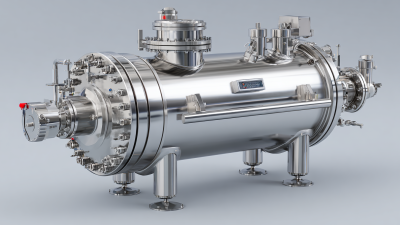

A homogenizer machine is a specialized piece of equipment designed to break down and disperse particles in a liquid, creating a uniform and stable mixture. This process is essential in various industries, particularly in food and beverage, pharmaceuticals, and chemical manufacturing. By using high pressure, homogenizers effectively reduce particle size, ensuring that emulsions and suspensions are consistent, which enhances the quality and shelf-life of products. According to a report from MarketsandMarkets, the global homogenizer market is expected to grow from $536 million in 2020 to $758 million by 2025, reflecting the increasing demand for uniformity in product formulations.

In the food industry, for example, the homogenization process plays a critical role in the production of dairy products such as milk and cream. It prevents separation and enhances mouthfeel, making products more appealing to consumers. A study published in the Journal of Dairy Science found that homogenized milk has a significantly longer shelf life compared to non-homogenized options due to its improved stability against microbial growth. In pharmaceuticals, homogenizers help in formulating consistent drug solutions, making them essential for product efficacy and patient safety. The ability of homogenizers to create uniform particle sizes is vital for drug delivery systems, where consistency can greatly influence the therapeutic effects.

Overall, homogenizers are indispensable in multiple sectors, enabling manufacturers to meet high-quality standards and consumer expectations while ensuring product effectiveness and longevity.

The history and evolution of homogenization technology trace back to the late 19th century when it emerged as a crucial process for improving product consistency and stability in various industries. The first homogenizer was invented in 1899 by French engineer Auguste Gaulin, initially designed to prevent cream from separating in milk. This invention laid the groundwork for a wide range of applications, illustrating the importance of creating uniform particle sizes in emulsions, suspensions, and other mixtures.

As industries grew and diversified, so did the applications of homogenization. By the mid-20th century, advancements in technology led to more efficient and powerful homogenizers, significantly impacting food processing, pharmaceuticals, and cosmetics sectors. A report from Grand View Research indicates that the global homogenizer market was valued at approximately $380 million in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2021 to 2028. This growth reflects an increasing demand for improved quality and consistency in products ranging from dairy items to fine chemicals, underscoring the ongoing relevance of homogenization techniques in modern industry.

The evolution of homogenization technology continues with the advent of new materials and methodologies, such as high-pressure homogenization and ultrasonic homogenization, which enhance efficiency and energy savings. These advancements allow industries to produce higher quality products while minimizing waste and maintaining compliance with stringent regulatory standards. Recent studies have shown that effective homogenization can increase bioavailability in pharmaceuticals and improve taste profiles in food products, further cementing its role as a critical technological advancement across multiple sectors.

| Industry | Application | Homogenization Method | Benefits |

|---|---|---|---|

| Food & Beverage | Milk, sauces, emulsions | High-pressure homogenization | Improved texture, shelf life |

| Pharmaceuticals | Vaccines, creams, ointments | Ultrasonic homogenization | Enhanced bioavailability, uniformity |

| Cosmetics | Lotions, serums, emulsions | Mechanical homogenization | Stable formulations, smoother application |

| Chemical | Paints, coatings, inks | Homogenizing mills | Improved dispersion, color consistency |

| Biotechnology | Cell disruption, protein extraction | Pressure homogenization | Efficient extraction, higher yield |

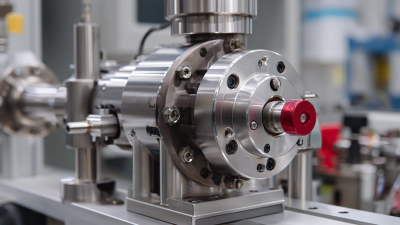

Homogenizer machines are essential devices employed across various industries for their ability to create uniform particle sizes and improve the stability of products. The fundamental principle behind a homogenizer's operation is the reduction of larger particles into smaller, evenly distributed ones. This process is achieved through mechanical forces, typically using high-pressure pumps to force the mixture through narrow spaces or valves, causing shear forces that break down the particles.

In practice, homogenizers operate on the principle of turbulence and cavitation. When a liquid mixture is forced at high velocity through a small aperture, it creates turbulent flow, which enhances the interactions between particles. Additionally, cavitation occurs as local pressure drops, resulting in the formation and collapse of microscopic bubbles that further agitate the mixture, thereby achieving uniformity. This mechanism is crucial in industries like food and beverage, pharmaceuticals, and cosmetics, where the consistency and stability of products are paramount for quality and safety. By ensuring even dispersion of components, homogenizers help maintain product integrity and enhance shelf life, thus playing a vital role in production processes.

Homogenizer machines are essential tools in various industries, enabling the uniform mixing of liquids and the breakdown of particle sizes. There are several types of homogenizers available, each with distinct features that cater to different applications. In the food and beverage industry, high-pressure homogenizers are widely used to produce stable emulsions, ensuring that products like milk and sauces maintain a consistent texture and flavor. In pharmaceuticals, ultrasonic homogenizers facilitate the creation of fine emulsions and suspensions, enhancing the bioavailability of medications.

Another type, batch homogenizers, is preferred in cosmetic manufacturing for their efficiency in processing small quantities while allowing for precise control over the homogenization process. In contrast, inline homogenizers continuously process larger volumes, making them ideal for high-demand production environments. Understanding these types and their functionalities can aid businesses in selecting the right homogenizer for their specific needs.

Tips: When selecting a homogenizer, consider the viscosity of the material and the desired particle size reduction. Regular maintenance is crucial to ensure optimal performance and longevity, as neglecting it can lead to efficiency losses in production. Additionally, always consult with technical experts to align the homogenizer's specifications with your production goals.

Homogenizers play a crucial role in the food and beverage industry by ensuring a uniform consistency and texture in various products. These machines work by breaking down large particles into smaller ones, thereby creating stable emulsions and suspensions. This process is essential for products like milk, where homogenization prevents cream from rising to the top, resulting in a smooth and consistent texture. In sauces, dressings, and beverages, homogenizers ensure that the ingredients are evenly dispersed, enhancing both the mouthfeel and the visual appeal of the final product.

Additionally, homogenization can enhance the nutritional profile of food products. By reducing particle size, more nutrients become available for absorption, making fortified beverages and dairy products more effective. In ice cream production, homogenizers contribute to the formation of smaller ice crystals, which leads to a creamier texture. The ability to control the viscosity and stability of products also helps in extending shelf life, making homogenization an indispensable step in modern food processing. Overall, the applications of homogenizers are vast and vital in delivering high-quality food and beverage products to consumers.

Homogenizers play a crucial role in both pharmaceutical and cosmetic manufacturing by ensuring uniformity and stability in products. In the pharmaceutical industry, homogenizers are employed to create emulsions and suspensions that enhance the bioavailability of active ingredients. By breaking down the particles into smaller sizes, the homogenization process improves the absorption and efficacy of medications, leading to better patient outcomes. This process also helps in maintaining consistent textures and appearances in liquid formulations, which is vital for patient compliance.

In the cosmetic sector, homogenizers aid in the formulation of creams, lotions, and other beauty products by producing a stable emulsion that prevents separation. This not only enhances the visual appeal of the products but also ensures that active ingredients are evenly distributed, providing consistent performance during use. The innovation of homogenization technology allows manufacturers to explore new textures and formulations, catering to diverse consumer preferences.

Tips: When selecting a homogenizer for pharmaceutical or cosmetic applications, consider factors such as the viscosity of your formulations and the desired particle size for optimal results. Additionally, regular maintenance and adherence to strict hygiene protocols are essential to ensure the longevity of the equipment and the safety of the products being produced.

The future of homogenization techniques is poised for significant advancements as industries increasingly demand more efficient and sustainable processes. Emerging technologies, such as high-pressure homogenization and ultrasound-assisted homogenization, are setting new standards for product consistency and quality. These innovations not only enhance the physical properties of various substances—such as emulsions and suspensions—but also allow for the reduction of energy consumption during processing. The integration of smart technologies, like IoT and AI, enables real-time monitoring and optimization of homogenization processes, ensuring that manufacturers achieve peak performance while minimizing waste.

Tip: When selecting a homogenizer, consider the specific requirements of your process, including the material's viscosity and the desired particle size. This helps in choosing the most suitable technology for your application's unique needs.

In addition to technical advancements, a growing emphasis on sustainability is influencing the future of homogenization. Industries are exploring eco-friendly practices that reduce water usage and energy consumption. This shift not only aligns with global sustainability goals but also meets the increasing consumer demand for environmentally conscious products. The incorporation of green practices in homogenization will become a key differentiator for companies looking to innovate while remaining responsible.

Tip: Regular maintenance and calibration of homogenizer equipment are essential for maximizing efficiency and prolonging the lifespan of your machines. Always follow the manufacturer's guidelines to ensure optimal performance.

: Homogenizers ensure uniformity and stability in pharmaceutical products by creating emulsions and suspensions that enhance the bioavailability of active ingredients, leading to improved absorption and efficacy of medications.

In cosmetics, homogenizers produce stable emulsions that prevent ingredient separation, enhance visual appeal, and ensure consistent performance of creams and lotions.

Consider the viscosity of your formulations and the desired particle size for optimal results, as these factors will influence your choice of homogenizer technology.

Future trends include high-pressure homogenization and ultrasound-assisted homogenization, focusing on product consistency, quality, and reducing energy consumption during processing.

These technologies enable real-time monitoring and optimization of homogenization processes, allowing manufacturers to achieve peak performance while minimizing waste.

There is a growing focus on eco-friendly practices that reduce water usage and energy consumption in homogenization, aligning with global sustainability goals and consumer demand for environmentally conscious products.

Regular maintenance and calibration are essential for maximizing efficiency, prolonging the lifespan of homogenizers, and ensuring optimal performance in production.

Maintaining consistent textures and appearances in liquid formulations through homogenization can improve patient compliance by ensuring a more pleasant experience when taking medications.

Advancements in homogenization technology allow manufacturers to experiment with different formulations and textures, catering to diverse consumer preferences in the beauty market.

Incorporating eco-friendly practices can serve as a key differentiator for companies, helping them innovate while meeting responsible sustainability standards and consumer expectations.

A Homogenizer Machine is an essential device used across various industries to achieve uniform consistency in products. It works by breaking down particles in a mixture, ensuring that components are evenly distributed. The technology has evolved over the years, progressing from simple mechanical methods to advanced machinery capable of fine-tuning particle size. Understanding the principles of homogenization, such as shear and pressure forces, is crucial for effectively utilizing these machines.

Homogenizer Machines find significant applications in the food and beverage sector, where they enhance product stability and texture, and in the pharmaceutical and cosmetic industries, where they ensure the uniformity of emulsions and suspensions. As advancements continue, future trends point towards more energy-efficient designs and innovative techniques that promise to further enhance the performance and versatility of homogenization processes.