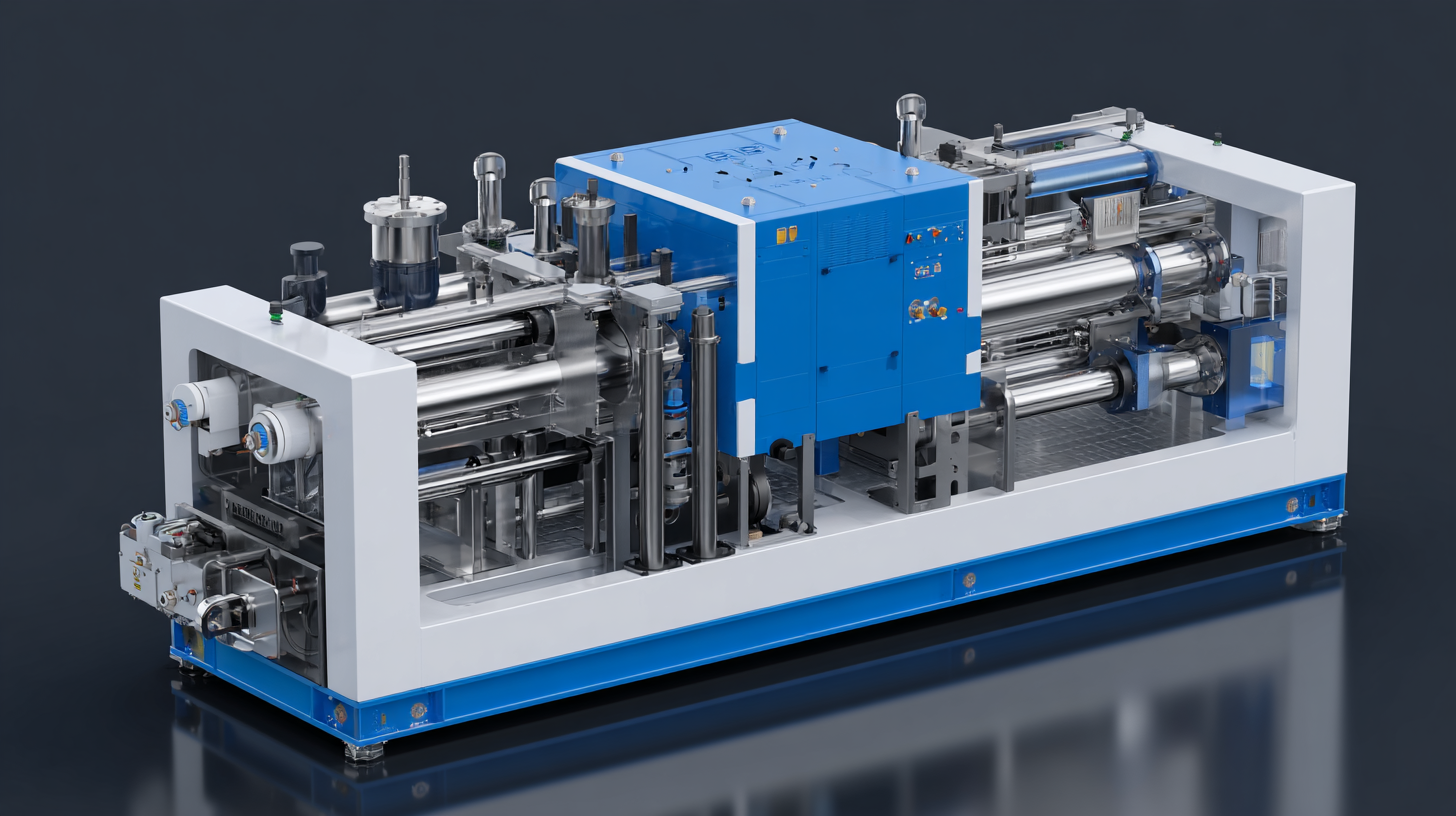

When it comes to modern manufacturing, you really can't overlook the importance of a High Pressure Cell Homogenizer. As industries push for better efficiency and higher-quality products, these high-tech devices play a crucial role in getting materials evenly dispersed at the molecular level. They’re pretty much essential in a bunch of fields—whether it's making medicines or whipping up food products. CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD totally gets how important this is and is dedicated to both researching and selling top-of-the-line high pressure homogenizers and microfluidizers. By offering the latest in nanotech solutions, CAS PETER helps meet the wide-ranging needs of today's manufacturing processes, making sure businesses can unlock the full potential of their products. In this blog, we’re gonna look at why High Pressure Cell Homogenizers are so vital, what benefits they bring to the table, and what other options you might find out there—because honestly, they’re pretty much a must-have in today’s fast-moving industrial world.

High pressure cell homogenizers are pretty much essential in today’s manufacturing world, especially in fields where you need super precise emulsification and tiny particle sizes. They’re especially great for things like trapping ingredients inside nanoliposomes—think of it as a fancy way to deliver active compounds more effectively. For example, recent research has shown that using high pressure homogenization to create vitamin C-loaded nanoliposomes can boost their absorption through the skin and make them work a lot better. This sort of thing is a game-changer for industries like pharma and cosmetics, where the consistency and quality of emulsions really matter.

What makes these homogenizers so effective? Well, they offer adjustable pressure settings and can handle different batch sizes, which is pretty convenient. Not only do they break down particles more efficiently, but they also keep emulsions stable—something that’s pretty important for preserving liquids in foods too. As the food industry moves more and more toward non-thermal preservation methods, high pressure homogenization becomes a favorite because it can change the molecular structure of liquids without damaging their quality. All these points really highlight how crucial high pressure cell homogenizers are in pushing innovation forward across a bunch of manufacturing sectors.

What makes these homogenizers so effective? Well, they offer adjustable pressure settings and can handle different batch sizes, which is pretty convenient. Not only do they break down particles more efficiently, but they also keep emulsions stable—something that’s pretty important for preserving liquids in foods too. As the food industry moves more and more toward non-thermal preservation methods, high pressure homogenization becomes a favorite because it can change the molecular structure of liquids without damaging their quality. All these points really highlight how crucial high pressure cell homogenizers are in pushing innovation forward across a bunch of manufacturing sectors.

High pressure cell homogenizers have really become a must-have in modern manufacturing these days, especially when it comes to improving product quality and keeping things consistent. Basically, they use super intense shear forces—thanks to high pressure—to break down cell structures pretty effectively. That’s why you’ll see them often used in processes like making nanocellulose from lignocellulosic biomass. And nowadays, folks are also combining them with cool new tech like enzymes and cold plasma. These pairings help get the most out of valuable materials while wasting as little as possible—that’s pretty smart, right?

But it’s not just about extraction. These homogenizers also do a great job at making products safer by killing bacteria and other germs without needing high heat. That’s a big deal because it helps keep heat-sensitive stuff intact. So, really, high pressure homogenization is not just about boosting efficiency—it’s also a smart move for making manufacturing more sustainable. As industries keep exploring new processing tricks, I think these tools are going to stay really important across different sectors, helping push things forward.

| Advantages | Description | Applications |

|---|---|---|

| High Efficiency | Processes materials quickly, reducing operational time. | Food, pharmaceuticals, and cosmetics. |

| Enhanced Homogeneity | Provides uniform particle size distribution. | Emulsions and suspensions. |

| Versatility | Can process various types of materials. | Biotechnology and chemical industries. |

| Improved Quality | Enhances the quality and stability of products. | Nutraceuticals and specialty chemicals. |

| Cost-Effectiveness | Reduces material waste and improves yield. | Manufacturing processes across sectors. |

High pressure cell homogenizers have really become essential in a bunch of industries these days. I mean, they’re fantastic at breaking cells apart efficiently and making sure products stay consistent. Take pharma, for instance—homogenization is a key step in formulating drugs, helping to shrink particle sizes significantly. I came across a report from MarketsandMarkets that says the global market for pharmaceutical applications of these machines is expected to grow at a compound annual growth rate of about 6.8% from 2023 through 2028. That just goes to show how much demand there is for really precise formulations.

And it’s not just pharma! The food industry also relies a lot on high-pressure homogenizers. They’re great for creating stable emulsions and uniform mixes, which really affect the texture and taste of all kinds of foods. One recent study in food tech mentioned that around 45% of food manufacturers noticed a pretty big bump in product quality after starting to use high-pressure homogenization. Plus, this tech not only makes the final product better but can also cut down manufacturing costs by reducing waste—always a win.

A quick tip: When you’re picking out a high-pressure cell homogenizer, don’t forget to check what maximum pressure it can handle and whether it’s compatible with your materials. Picking the right machine can make a huge difference in how smoothly your production runs.

And another tip: Regular maintenance and calibration are key. Keeping your homogenizer in top shape helps it perform consistently and lasts longer, which can really save you money in the long run.

High-pressure cell homogenizers, or HPHs for short, really play a key role in making sure our modern manufacturing processes—especially in food and drinks—are consistent and top quality. Lately, I’ve seen studies showing that using microfluidization in fruit juice production not only boosts how much juice gets extracted but also keeps the nutrients intact, which is pretty cool. Plus, high-pressure homogenization can actually help lower the amount of microbes in products, meaning they stay fresh longer and are safer to enjoy. It’s like killing two birds with one stone!

And there's more—ultra-high-pressure homogenization (UHPH) has some pretty exciting potential when it comes to food innovation. For example, a recent study found that yogurts made with oils rich in polyunsaturated fatty acids didn’t just taste better—they also offered health perks, all while replacing traditional dairy fats. That’s a win-win, right? Plus, it’s a step toward making our food more sustainable.

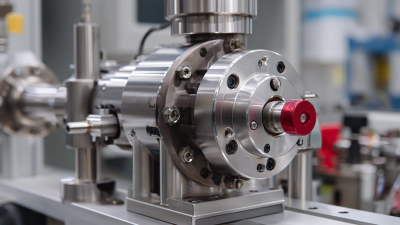

Oh, and understanding how particles hit the valves in these machines is super important. Researchers have used tiny visualizations to see how particles interact and what kind of wear and tear that causes. This stuff directly affects how good the final product turns out. All in all, these advances really highlight how essential HPHs are for achieving that perfect, consistent product—especially in such a competitive industry. It’s pretty fascinating how science and engineering together are helping us get better food all the time!

The future of high-pressure cell homogenizer tech looks pretty promising, with some really exciting advancements on the horizon—mainly driven by new innovations and a push for better efficiency. You know, manufacturers are on the lookout to squeeze out the best product quality and boost production rates, and that's where smart technologies like IoT connectivity and data analysis come into play. These upgrades not only make operations smoother but also allow for real-time monitoring and tweaking, which helps folks keep results steady and cut down on downtime.

If you're looking to get the most out of your high-pressure homogenizer, I’d suggest investing in systems that use machine learning for predictive maintenance. It’s a game-changer because it helps catch issues early, keeping your equipment running longer and avoiding unexpected breakdowns. Also, it's smart to choose suppliers that play nice with your existing automation setup—it just makes everything run more seamlessly and saves some cash in the process.

And here’s a trend that’s gaining steam—more focus on sustainability. Companies are coming up with energy-efficient models that use fewer resources but still deliver top-notch output. This is totally in line with the shift towards greener manufacturing practices, which is not only good for the planet but can also save money over time.

When you're picking out a high-pressure homogenizer, look for ones that boast energy-saving features and are made with eco-friendly materials. Going green like this not only boosts your company’s social responsibility efforts but can also lead to some savings down the line. Win-win, right?

: High pressure cell homogenizers are utilized in modern manufacturing to enhance emulsification, particle size reduction, and the encapsulation of compounds, particularly in industries like pharmaceuticals and cosmetics.

They enhance product quality by effectively disrupting cell structures, improving extraction rates, reducing microbial loads, and maintaining nutritional integrity, especially in food and beverage applications.

Yes, high pressure homogenization inactivates bacteria without using high-temperature treatments, preserving the integrity of heat-sensitive ingredients.

Adjustable pressure settings allow users to optimize processes for different batch sizes and specific product requirements, enhancing efficiency and control over the emulsification process.

It enables efficient extraction while minimizing resource wastage and helps in producing sustainable food formulations by enhancing health benefits through innovative ingredient substitutions.

Microfluidization improves extraction rates and maintains the nutritional integrity of juices, while potentially extending their shelf life by reducing microbial loads.

High pressure homogenization is a non-thermal preservation method that modifies the molecular structure of liquids, enhancing the stability of emulsions and contributing to longer product shelf life.

Understanding particle impact in homogenizer valves is essential for improving processing efficiency and longevity of equipment, which directly affects the quality of the final product.

UHPH enhances encapsulation capabilities and allows for the use of healthier ingredient alternatives, improving sensory qualities and contributing to food sustainability.

They are essential for process intensification, ensuring microbial safety, enhancing product quality, and promoting innovative manufacturing practices across various industries.

High Pressure Cell Homogenizers are really important in today’s manufacturing world. They help improve how things run and make sure the products stay consistent. These machines are pretty sophisticated, offering precise control over processing conditions — which is a big deal for industries that need uniform particle sizes and stable emulsions. But it’s not just about efficiency; these homogenizers also make it easier to extract the active ingredients and significantly boost the overall quality of the final products. That means happier customers in the end, for sure.

You’ll find these machines used across a bunch of different industries — think pharmaceuticals, food and beverages, and cosmetics. They really help create products that perform better and have a better feel. Looking ahead, the tech behind High Pressure Cell Homogenizers keeps getting better, opening doors to exciting innovations, especially in nanotechnology. At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re dedicated to offering top-of-the-line homogenization solutions to meet the ever-changing needs of various industries, helping our clients stay competitive in this fast-moving marketplace.