You know, with how the demand for advanced drug delivery systems keeps climbing and how nanotech keeps making its way into pharmaceuticals, it's no surprise that we've seen some pretty exciting breakthroughs in formulation techniques — especially when it comes to Liposome Extruders. Recent industry reports say the liposomal drug delivery market could hit around $6.92 billion by 2027, which just shows how crucial it is to really get a handle on liposome tech if you want to nail those formulations.

CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is really leading the charge with cutting-edge high-pressure homogenizers and microfluidizers, all aimed at giving industries top-notch nanotech solutions. As we dive into this ultimate guide on mastering Liposome Extruder technology, we'll go over how it works, where it can be used, and what benefits it offers — giving formulators the know-how to create even more effective therapies.

Getting the hang of liposome extruder technology is really important if you wanna develop effective liposome-based formulations. Basically, this tech works by manipulating lipid bilayers to form liposomes — tiny little vesicles, often just nanometers in size, that can carry drugs or other active ingredients. The main idea is to push a mixture of lipids through a narrow membrane under controlled pressure, which helps produce liposomes that are uniform in size and more stable overall. This process not only boosts how well the liposomes can encapsulate substances, but also makes sure you get consistent results every time — which is a big deal, especially in pharma.

When diving into the technical details, things like the type of membrane you choose, the temperature during extrusion, and how many times you go through the process really matter. Each one influences the size and structure of the final liposomes. For example, smaller pores usually produce smaller liposomes, which can be a real plus because they tend to stay in the bloodstream longer. Plus, understanding how all these factors work together gives formulators the flexibility to tweak liposome features based on specific therapeutic needs — leading to better drug delivery systems overall.

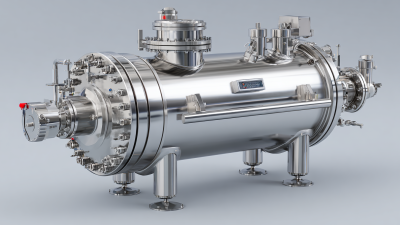

When it comes to nanotech, getting a good handle on liposome extruder tech is pretty much essential if you want to get the best formulations. Knowing what the key parts of a liposome extruder are can make a huge difference for both researchers and manufacturers. At the heart of this setup, you’ll find a high-pressure homogenizer, which really is a game-changer. It gives you precise control over pressure and shear forces, making sure lipids and active ingredients mix evenly. That’s how you end up with stable, uniform liposomes—super important for drug delivery stuff.

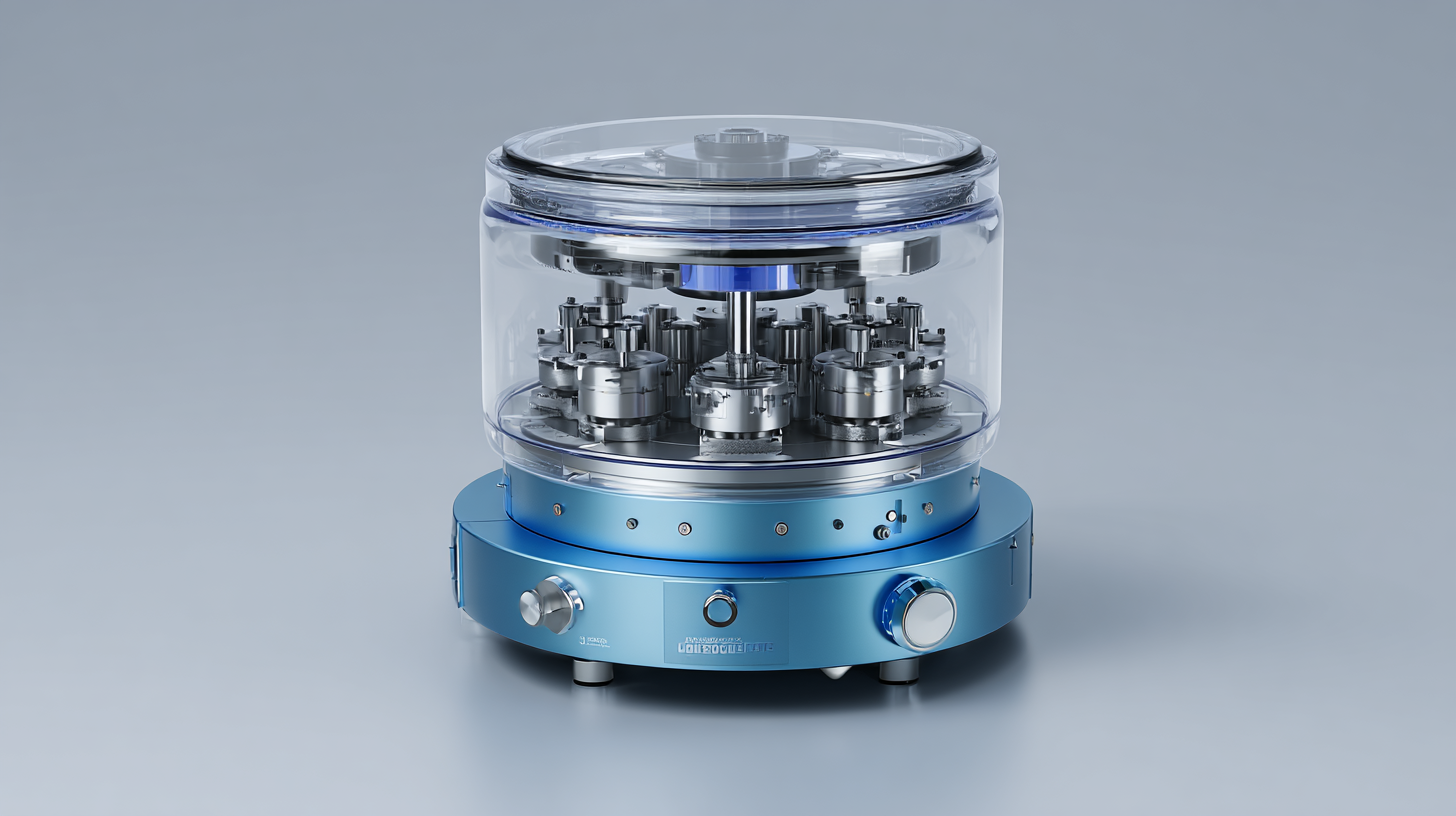

Then there's the microfluidizer — another piece of the puzzle that helps ramp up production efficiency. These devices use microfluidics to create tiny interactions that ensure the liposomes get mixed thoroughly and their size gets reduced effectively. Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are really stepping up in this area, offering advanced high-pressure homogenizers and microfluidizers tailored for all sorts of industrial needs. Their expertise isn’t just about hitting the right particle sizes; it also helps improve stability and effectiveness of liposomal products, which can lead to some pretty exciting breakthroughs in pharma and cosmetics.

| Component | Description | Function | Material | Cost Estimate (USD) |

|---|---|---|---|---|

| Extruder Chamber | The main part where liposome formation occurs. | Houses the lipid mixture and applies shear forces. | Stainless Steel | $2000 |

| Heat Exchanger | Regulates the temperature of the lipid mixture. | Ensures optimal temperature for liposome stability. | Copper | $1500 |

| Pumping Mechanism | Moves the lipid mixture through the extruder. | Controls the flow rate and pressure. | High-Performance Polymer | $1000 |

| Membrane Filter | Filters extruded liposomes to desired sizes. | Ensures uniformity in liposome size distribution. | Polyethersulfone (PES) | $300 |

| Control Panel | Interface for monitoring and controlling the process. | Provides user control over temperatures and pressures. | Aluminum | $500 |

When you're looking at liposome extrusion, deciding between doing it manually or going for an automated setup can really make a difference in both how good your results are and how efficient the whole process feels. Manual extrusion is more of a hands-on thing—you, the operator, need to keep an eye on things like pressure and temperature, making adjustments on the fly. It’s pretty flexible and lets you tweak things instantly based on what you observe, which is great if you want that extra level of control. But, honestly, it can be kinda slow, and it might lead to some inconsistencies—especially when you’re trying to produce larger batches.

On the flip side, automated liposome extruders bring a whole new level of convenience. They run the process under carefully programmed conditions, which helps make sure everything's uniform—like consistent liposome size—and boosts how well your molecules get encapsulated. Sure, investing in these systems costs more upfront, but in the long run, they save you time and help keep things reliable and reproducible. If you’re aiming for top-notch quality and efficiency, going automated might be the smarter move. By knowing the perks and drawbacks of each approach, formulators can better pick the right method to match their goals and what they’re working towards.

Tuning the formulation parameters is really key when it comes to improving how we produce liposomes, and honestly, it’s a process that needs quite a bit of attention to detail. The final quality and how well they work mostly hinge on things like the lipid mixture, the amount of active ingredients, and the method you use to prepare them. Small tweaks, like changing the ratios of lipids or choosing the right stabilizers, can make a big difference in the size, shape, and stability of the liposomes you end up with. It’s super important to do thorough, systematic studies to figure out what works best for the specific therapeutic goals you're aiming for.

Temperature control during extrusion is another big deal. Heating things up can help form those lipid bilayers more nicely, but if it gets too hot, you risk degrading the lipids. So, keeping the temperature just right is crucial for making sure everything disperses evenly and that the active ingredients get properly encapsulated. Plus, playing around with things like the number of extrusion cycles and the type of membrane filter you use can really fine-tune the characteristics of your liposomes, leading to better delivery systems—whether for drugs or nutraceuticals. All in all, by carefully tweaking and optimizing these parameters, formulators can create liposomal formulations that perform better and are more stable in the long run.

When it comes to liposome extrusion, there are a few common bumps in the road that can make it tricky to get the perfect formulation. For starters, making sure the liposomes are all about the same size and keeping their structure intact can be pretty challenging. For example, if the shear stress during extrusion isn’t consistent, you might end up with a bunch of liposomes that vary a lot, which could mess with how well the drug gets delivered. On the bright side, new tech like semi-solid extrusion 3D printing (SSE 3DP) seems pretty promising. It might help fix some of these issues by giving us more control over the environment during production, leading to more precise and uniform formulations.

Here’s an idea—using a design of experiments (DoE) approach when developing liposomal formulations can be a real game-changer. It helps find the best combination of factors, making the whole process more predictable and efficient. Plus, have you heard about the ethanol injection method? It’s great for quickly producing small unilamellar liposomes, which could really speed things up without sacrificing quality.

Another big challenge is keeping sensitive compounds stable inside the liposomes. That’s where techniques like microfluidics come into play—they can boost the stability of probiotics and other fragile ingredients, ensuring they stay viable in the final product. By mixing in these cutting-edge production methods, manufacturers can tackle these problems head-on, ultimately leading to more innovative and effective drug delivery systems.

Lately, there's been some pretty exciting progress in liposome extruder tech, and honestly, it’s opening up new doors for drug delivery that could really tackle some of the biggest challenges in pharma. The worldwide nanomedicine market is growing super fast—people are predicting it'll hit around $350 billion by 2025! That just goes to show how much more researchers and companies are turning to delivery methods like liposomes, which boost how well drugs get into the body. Not only do they make drugs more bioavailable, but they also let us target specific areas—an absolute game-changer when it comes to treating tricky diseases like cancer. In fact, recent studies show that using liposomal formulations can really boost how effective treatments are—more than half of cancer therapies now incorporate liposomes, which is pretty remarkable.

Plus, the whole micro and nano-encapsulation thing is evolving too. It’s enabling the creation of long-lasting transdermal delivery methods, with innovations like microneedles and adhesive patches becoming more common. These new options give patients easier, less invasive ways to get their meds, which is awesome. By combining these approaches with liposome manufacturing, we’re looking at better compliance and fewer side effects compared to traditional meds. Looking ahead, the combo of advanced liposome tech and other cutting-edge encapsulation methods is likely to lead to some truly groundbreaking treatments down the line.

: Liposome extruder technology manipulates lipid bilayers to create liposomes by forcing a lipid suspension through a narrow membrane under controlled pressure, resulting in uniform liposome size and enhanced stability.

Uniform size enhances encapsulation efficiency and ensures reproducibility in formulations, which is crucial for pharmaceutical applications, leading to better drug delivery systems.

Smaller membrane pore sizes result in smaller liposome diameters, which can improve circulation time in the bloodstream, thus enhancing therapeutic efficacy.

The key components include a high-pressure homogenizer, which controls pressure and shear forces for uniform dispersion, and a microfluidizer, which enhances mixing and size reduction of liposomal formulations.

Common challenges include achieving uniform size distribution, maintaining structural integrity, and the stability of bioactive compounds within the liposomes.

Technologies like semi-solid extrusion 3D printing can create precise environments for liposome production, potentially overcoming issues related to size distribution and structural integrity.

DoE methodology optimizes the combination of factors influencing the extrusion process, improving predictability and efficiency in developing liposomal formulations.

The ethanol injection technique allows for the rapid production of small unilamellar liposomes while maintaining quality, streamlining the formulation development process.

Utilizing encapsulation strategies such as microfluidics can enhance the stability of sensitive compounds, ensuring their viability in functional formulations.

Improved liposome extruder technology can lead to breakthroughs in drug delivery systems, enhancing the efficacy and stability of pharmaceutical and cosmetic products.

In our 'Ultimate Guide to Mastering Liposome Extruder Technology for Better Formulations,' we take a deep dive into the key principles and components of liposome extruders. We really break down how these devices work, so you get a clear picture of what's going on. We also compare manual and automated extrusion methods, pointing out the pros and cons of each—because let's face it, choosing the right approach can really make a difference. Plus, we focus on fine-tuning formulation parameters to boost liposome production, and we talk about common problems you might run into during extrusion, along with some practical tips to solve them.

As technology in liposome extruders keeps evolving, the future looks pretty exciting. New innovations are on the horizon, promising to make formulation processes more efficient and effective. Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we're all about pushing forward with high-pressure homogenization solutions. We're eager to stay at the cutting edge of these advancements so we can better serve the different industries we work with.