In the world of lab research and development, finding efficient ways to prepare samples is super important. One process that really stands out is homogenization — yeah, that’s the key to getting consistent, uniform mixtures, especially in industries like pharmaceuticals, food and drink, and biotech. I came across a report from Research and Markets that says the global market for homogenizers is expected to hit around $1.54 billion by 2025. That just shows how much this equipment is becoming a must-have across different sectors. As labs try to improve their methods, picking the right homogenizer isn’t as straightforward as it used to be. You really need to understand what’s out there and what each machine can do best.

When you're on the hunt for the perfect homogenizer for your lab, it’s a good idea to look at both the technical specs and how easy or beneficial they are to use. There’s a whole range of options — from high-pressure systems to ultrasonic ones — each suited for different samples and outcomes. Having a helpful guide with technical details and real-world examples can make a huge difference in helping you make the right choice. Plus, resources like the "Homogenizer PDF" give you all the key points and comparison tools you need to navigate this pretty complex landscape. By taking a step-by-step approach to choosing your equipment, your lab can run more smoothly, be more reliable, and most importantly, produce better research results.

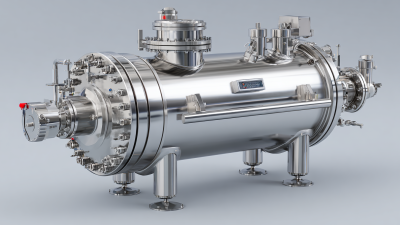

When selecting the right laboratory homogenizer, several key factors come into play to ensure it meets your specific research needs. First, consider the sample types and volumes you will be working with. High-pressure homogenizers and microfluidizers offer unique advantages depending on the physical properties of the materials being processed. For instance, high-pressure homogenizers are ideal for larger volumes and tougher samples, while microfluidizers excel in achieving uniform particle sizes in smaller batches.

Another essential factor is the desired outcome of the homogenization process. Different homogenizers can produce varying results in terms of particle size reduction, emulsion stability, and overall sample consistency. CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD specializes in providing tailored solutions for high-pressure homogenization and microfluidic applications, allowing researchers to optimize their processes based on the specific demands of their projects. Understanding these parameters will aid in making an informed decision that aligns with your laboratory objectives.

When you're trying to pick the right homogenizer for your lab, it’s really helpful to get a good grasp of the different types out there. Honestly, knowing whether to go for a high-pressure homogenizer or a microfluidizer can make a big difference depending on what you’re working on. High-pressure homogenizers are great when you need to break down liquids into uniform particles—think pharmaceutical, food, or cosmetic stuff. Meanwhile, microfluidizers use these controlled shear forces to mix and disperse materials at a really tiny scale, which is perfect if you're into nanotech or biotech projects.

At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we specialize in these cool, innovative homogenization tech. We offer both high-pressure homogenizers and microfluidizers, so whatever your industry needs, chances are we’ve got you covered. We’re all about helping our clients get top-notch efficiency and precision with our solutions. Once you understand the benefits of each method, you’ll be able to make smarter choices—improving your research results while streamlining your processes for better quality and productivity.

When you're choosing a homogenizer for your lab, it’s really important to get a good grasp on its key features and specs. One thing to think about is how it actually homogenizes – whether it’s ultrasonic, high-pressure, or rotor-stator. Each of these methods has its own perks, depending on what kind of sample you're working with and how fine you need the particles to get. For example, ultrasonic homogenizers are pretty great for sensitive or delicate materials, while high-pressure models tend to do a better job with creating stable emulsions and making everything uniform.

Here’s a tip: Make sure the capacity of the homogenizer matches the sample volumes you're working with. If you go for a bigger machine than you need, it could end up being a waste of money and less efficient.

Another thing to keep in mind is the power and speed settings. Having a variable speed option is a real plus because it gives you the flexibility to tweak things to suit your project. Also, think about how easy it is to clean and maintain the machine. That stuff really affects how smoothly your lab runs and how hygienic everything stays.

Pro tip: look for homogenizers that have removable parts and smooth surfaces—makes cleaning a lot easier. And check whether they’re compatible with different kinds of sample containers—that can save you a lot of hassle down the road.

| Feature | Description | Importance |

|---|---|---|

| Speed Range | Ability to adjust the speed from low to high RPM | High |

| Volume Capacity | Suitable for small (1 mL) to large (1 L) sample sizes | High |

| Compressor Cooling | Features active cooling to prevent overheating | Medium |

| Ease of Cleaning | Design allows for simple disassembly and cleaning | High |

| Noise Level | Decibel levels during operation | Medium |

| Power Source | Electric, battery-operated, or both | Medium |

| Safety Features | Protection mechanisms against overload and excess heat | High |

So, if you're working in a lab in 2023 and trying to pick out the right homogenizer, trust me, it can make a pretty big difference in how your research turns out. You’ve probably heard of some of the big players like QIAGEN, Thermo Fisher Scientific, and Bertin Instruments—they're pretty much leading the pack right now. I recently saw a report from Research and Markets that says the global market for lab homogenizers is expected to grow at about 6.7% CAGR from 2021 to 2028. That just shows how much folks are relying on these tools across all kinds of scientific fields.

When you're choosing one, a few things are worth thinking about—like what kind of samples you'll be working with, how efficient you need the homogenization to be, and how user-friendly the equipment is. For example, QIAGEN's really well-known for its awesome performance with DNA and RNA prep. Thermo Fisher has a solid selection that works great whether you're doing high-volume stuff or smaller, more precise applications. And Bertin Instruments? They've got some pretty innovative designs and are known for being versatile, especially when dealing with tough biological samples.

Pro Tip: Before you hit 'buy,' try to really figure out what your experiments need. Also, keep in mind whether the device will scale with your work and if it’s compatible with your existing lab protocols—this way, things won’t be a hassle later on. And hey, don’t forget to check out reviews or user feedback. Sometimes those little insights can save you a lot of headaches and help you pick a reliable, effective homogenizer.

Keeping your homogenizer in good shape and running smoothly is honestly pretty important if you want consistent results in your lab. The best way to do that? Regular maintenance, starting with cleaning. After each use, it's a good idea to take it apart and clean all the parts—especially the rotor and stator, since those are the key players in getting things mixed properly. Don’t forget to set up a routine check-up schedule to spot any signs of wear or damage before they become a bigger problem.

When it comes to making your homogenizer work like a charm, pay attention to settings like speed, time, and the amount of sample you're working with. Cranking up the speed for thicker samples can make a big difference, and running a few cycles might be needed if you're dealing with tougher materials. Also, keep an eye on the temperature during processing—getting too hot can mess with sensitive samples. Follow these simple tips, and you'll keep your homogenizer performing at its best, giving you consistent, reliable results every time.

When you're picking out a homogenizer for your lab, it’s really about finding that sweet spot between cost and quality. I get it—budget’s often tight, and it’s tempting to go for the cheaper options. But honestly, those initial savings might end up costing you more in the long run if the machine doesn't perform well or keeps breaking down. Skimping on quality can lead to inconsistent results, wasting time and resources, and it might even mess up your overall research. Investing a bit more upfront in a good homogenizer can pay off by providing more accurate sample processing, better reproducibility, and saving you headaches down the line.

To really get the best bang for your buck, take a close look at what features matter most for your lab — stuff like speed, capacity, and how easy the machine is to operate. Sometimes, a higher-end model might seem pricey at first glance, but it’s often packed with tech that'll save you time and cut down on maintenance.

So, don’t just focus on the sticker price; think about the long-term benefits and how it can make your work smoother and more efficient. If you weigh both cost and quality carefully, you'll be able to pick something that fits your budget but also meets your needs. Trust me, it’s worth it in the end.

: The two main types of homogenizers are high-pressure homogenizers and microfluidizers.

High-pressure homogenizers are ideal for applications in the pharmaceutical, food, and cosmetic industries that require substantial pressure to achieve uniform particle sizes in liquids.

Microfluidizers use controlled shear forces to disperse and mix materials at the micro-scale, making them suitable for advanced applications in nanotechnology and biotechnology, whereas high-pressure homogenizers focus on achieving uniformity through high pressure.

Laboratories should consider cost versus quality, as well as specifications like speed, capacity, and ease of use that align with their specific needs.

Lower-priced homogenizers can compromise on performance and reliability, leading to inadequate homogenization, inconsistent results, and inefficient resource use.

Investing in a quality homogenizer can ensure precise sample processing, better reproducibility, enhanced efficiency in experiments, and may reduce the need for frequent maintenance.

By considering both cost and quality, laboratories can make informed decisions that meet their demands while staying within budget while achieving better operational efficiency and research outcomes.

CAS PETER specializes in high-pressure homogenizers and microfluidizers, providing tailored solutions for diverse industrial requirements and focusing on nanotechnology applications.

Inadequate homogenization can lead to inconsistent results, waste of resources, and ultimately a negative impact on overall research outcomes.

Factors such as speed, capacity, and ease of use can vary significantly between different homogenizer models, affecting their suitability for specific lab applications.

Picking the right homogenizer for your lab isn't just about size or price — it's really about understanding your specific needs. Things like what kind of samples you're working with, how much material you need to process, and what kind of results you're after all matter. It’s helpful to compare different types—say, high-pressure homogenizers versus microfluidizers—to see which one really fits your application. When you're choosing, don’t forget to think about features like how efficient it is, whether it's user-friendly, and how much effort it takes to keep it running smoothly.

By 2023, there are some solid brands out there offering devices that strike a good balance between cost and quality, so labs can find something that gives them real value for their money. For instance, companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD. focus on high-pressure homogenization and can really support researchers working with nanotech. If you're looking for more details, especially tech specs or maintenance tips, check out the 'Homogenizer PDF'—it’s a handy resource to help make sure your equipment stays in top shape.

Overall, just take your time to consider what kind of homogenizer best suits your experiments—that way, you get better results with less hassle.