If you've ever looked into getting ultra-fine particles evenly dispersed, you probably already know that shear homogenizers are pretty much essential tools nowadays. They've become real game-changers across a bunch of industries like pharma, food, and cosmetics. I recently came across a market report from ResearchAndMarkets — interesting stuff — predicting that the global market for these gadgets is going to grow at over 8% annually from 2023 to 2030. That’s mostly because people are really craving better quality emulsions and dispersions. Over here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we totally get how tough it can be to meet those high standards with the traditional homogenization methods, especially when it comes to getting those tiny, uniform particles needed for advanced tech. That's why we’re putting a big focus on developing and selling high-pressure homogenizers and microfluidizers. Our goal? To offer smart, innovative nanotech solutions that keep up with what different industries need, helping them deliver products that perform better and look super consistent.

Hey, you know, shear homogenizers have really become essential tools when it comes to working with nanoemulsions. Like, they’re pretty much the go-to for getting those stable, nicely textured mixes we want. Basically, these devices throw high shear forces at the mixture, breaking down bigger droplets into tiny, nano-sized ones. This helps keep everything evenly distributed, which is super important for the stability of the whole emulsion. Think about industries like food, cosmetics, and pharma — in all those fields, having a consistent texture and longer shelf life isn’t just a bonus, it’s a must for satisfying customers.

A little tip, though: when you’re using a shear homogenizer, it’s key to find the right balance with processing time and speed. Push it too little, and the droplets won’t break down enough; go overboard with the shear, and you might end up messing with the product’s properties a bit. Also, adding stabilizers or emulsifiers that play nicely with your formulation can really give your nanoemulsion an extra boost in stability.

A little tip, though: when you’re using a shear homogenizer, it’s key to find the right balance with processing time and speed. Push it too little, and the droplets won’t break down enough; go overboard with the shear, and you might end up messing with the product’s properties a bit. Also, adding stabilizers or emulsifiers that play nicely with your formulation can really give your nanoemulsion an extra boost in stability.

Thanks to tech getting better all the time, shear homogenizers are becoming even more precise and controllable. Picking the right machine and setting it up correctly can seriously level up your nanoemulsions, making sure they meet all your quality standards. Don’t be afraid to experiment with different configurations — sometimes a small tweak can make all the difference in finding that perfect setup for your formulations.

As more industries start demanding ultra-fine particle dispersions, it's pretty clear that traditional shear homogenizers just don’t cut it anymore. Sure, these machines are great at breaking down particles into tiny sizes, but they can struggle with certain tricky materials—like those that are viscoelastic or need really precise control over particle size. That’s why a bunch of new technologies are starting to turn heads. Things like high-pressure homogenization, microfluidization, and ultrasonic dispersers are being looked at more closely now because they can achieve finer dispersions while using less energy and causing less wear on the equipment.

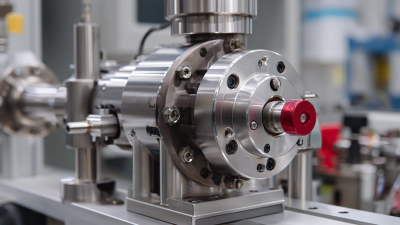

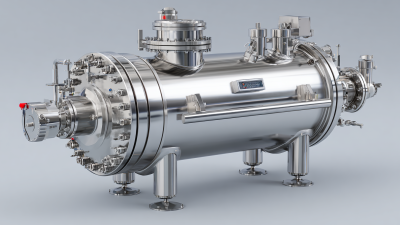

So, here’s the deal with high-pressure homogenizers: they work by pushing material through a narrow space at really high pressure, which helps break up particles without heating the mixture too much—something that’s super important for delicate formulas. Then there’s microfluidization, which uses tiny channels and controlled collisions—kind of like a high-speed, high-precision blender—that produce really uniform particles down to the nanometer scale. And ultrasonic dispersers? They use sound waves to shake things up in a liquid medium, which is pretty neat, especially for dispersing nanoparticles that might be tough to handle with old-school homogenizers. Each of these options has its own perks and downsides, so figuring out which one suits your specific needs is definitely worth some careful comparison.

| Technology | Dispersion Efficiency (%) | Particle Size Achieved (μm) | Energy Consumption (kW·h/kg) | Operational Costs ($/kg) |

|---|---|---|---|---|

| Conventional Shear Homogenizers | 85 | 1.5 | 0.5 | 0.20 |

| Microfluidizers | 95 | 0.5 | 0.3 | 0.15 |

| Ultrasonic Dispersers | 90 | 1.0 | 0.4 | 0.25 |

| High-Pressure Homogenizers | 92 | 0.8 | 0.35 | 0.18 |

| Electrohydrodynamic Process | 88 | 1.2 | 0.25 | 0.22 |

Lately, we've been seeing a big shift in how industries approach particle size reduction. There's a real buzz around high-efficiency shear homogenizers these days, mainly because everyone’s after finer, more uniform particles in their products. Recent tech improvements in high-pressure homogenization (or HPH for short) have proven just how effective they can be — not only in boosting the quality of food items but also in making them safer. When companies fine-tune their homogenization process, they can really level up, especially when it comes to producing chitin nanofibers. These fibers are gaining traction, especially in food packaging, thanks to their excellent barrier properties.

And it doesn’t stop there. Using high-pressure homogenization to tweak biopolymers—like the shear-thickening Mamaku polysaccharide from New Zealand’s black tree fern—is pretty impressive. This polymer can be customized through efficient homogenization methods to get the perfect viscosity and texture for new food ideas. Plus, recent research shows that ultra-high-pressure homogenization can transform microcrystalline cellulose, opening up even more possibilities for improving ingredient functions—not just in food, but also in pharma and other fields. Overall, as industries keep pushing for more efficiency and sustainability, it looks like shear homogenizers are only going to get more innovative and important in the future.

This chart illustrates the projected market growth for shear homogenizers in achieving ultra-fine particle dispersion from 2018 to 2023. The trends indicate a significant shift towards high-efficiency shear homogenizers as industries recognize the importance of optimizing particle size reduction techniques.

So, when you're trying to compare shear homogenizers with other dispersion methods, it's really important to think about what different industries actually need. These homogenizers are pretty awesome at breaking down particles into super tiny sizes—think as small as 100 nanometers. I came across a recent report by Smith and colleagues in 2022, and they highlight how using shear homogenizers can cut down processing times by up to 40% compared to the standard stirring methods. The thing is, those older methods usually end up with larger, less uniform particles. Not only does this mean better product quality with homogenizers, but it also actually saves money in the long run since your production runs smoother and faster.

And here's the interesting part: if you do the math on the costs, yeah, buying a shear homogenizer isn’t cheap upfront. But, over time, the savings really start to add up. Johnson & Co. in 2023 did a study showing that companies using these machines saw about a 30% drop in material waste because things are being mixed more efficiently. Plus, they used less energy too. Honestly, these little wins make a big difference, especially as markets get more competitive and the demand for finer particles keeps growing—whether you're into pharmaceuticals, food, or cosmetics. Basically, if you're serious about ramping up productivity and staying ahead, shear homogenizers are becoming pretty much essential.

You know, shear homogenization really makes a huge difference in pharmaceutical formulations. It helps make the drug products more uniform and stable, which is pretty important. When you crank up those high shear forces, you're basically breaking down particles into finer, more evenly distributed pieces. This not only boosts how well the body can absorb the drug but also ensures that the drug works consistently across different batches. Especially when you're dealing with tricky formulations like nanoparticles or emulsions, shear homogenizers become pretty much essential. They help fine-tune the particle size and distribution — a big deal for drugs that don’t dissolve easily. For drugs with poor solubility, keeping the particles evenly dispersed can make all the difference in how effective the treatment is.

And if you look at real-world examples, you really see the benefits. For example, lipid-based drug delivery systems tend to perform much better in terms of therapeutic effects after high shear processing. Same goes for vaccines — tweaking their formulations through shear homogenization has led to more stable and effective vaccines. It’s pretty awesome how versatile this tech is. As the pharma world keeps moving forward, I feel like we’ll rely even more on shear homogenizers to come up with innovative solutions that really improve patient care.

All in all, it’s clear that shear homogenization isn’t just a fancy lab trick — it’s actually a game-changer in making medicines better, safer, and more reliable.

As we dive deeper into the world of material science, you start to realize just how crucial shear homogenizers are for getting those ultra-fine particles evenly dispersed. These tools are pretty impressive—they give you tight control over particle size and even open doors to crafting new materials with better properties. Looking ahead, I think we can expect future versions to get smarter, maybe with more automation and real-time monitoring tech. That means you could tweak the process on the fly, which would ensure the final product is consistent and performs really well across different uses.

If you’re using shear homogenizers, a couple of tips might help you get the best results. First off, make sure the material’s viscosity isn’t too thick or thin for effective homogenization—that can really influence how well it works. Also, playing around with the speed and duration of the process can lead to improved dispersion. And don’t forget, keeping your equipment super clean and maintained is essential—not just to avoid cross-contamination but also to make sure your experiments are reproducible.

With the advent of new techniques like microfluidics and high-throughput screening, shear homogenizers are about to shake things up in developing nanomaterials. Industries like pharma, cosmetics, and even food tech are set to benefit from these advances—leading to some pretty exciting applications that we probably didn’t even imagine a few years ago. Staying on top of these trends is gonna be key for researchers and manufacturers wanting to stay competitive in this fast-changing field.

: The primary function of shear homogenizers in nanoemulsion technology is to utilize high shear forces to break down larger droplets into nanoscale sizes, creating a uniform distribution that enhances the stability and texture of the emulsion.

Particle size is important in emulsions because it affects the overall stability, texture, and shelf life of the product, which are crucial for consumer satisfaction in industries such as food, cosmetics, and pharmaceuticals.

To optimize the use of shear homogenizers, it's important to adjust the processing time and speed according to the desired particle size, and to incorporate compatible stabilizers or emulsifiers to further enhance the stability of the nanoemulsion.

Emerging alternatives to conventional shear homogenizers include high-pressure homogenization, microfluidization, and ultrasonic dispersers, which offer unique advantages in achieving finer dispersions and require less energy and wear on equipment.

High-pressure homogenizers work by forcing material through a narrow passage at high pressures, facilitating particle breakage without causing shear-related heating that could negatively affect sensitive formulations.

Recent trends in the particle size reduction industry show a shift towards high-efficiency shear homogenizers, driven by the demand for finer and more uniform particle dispersion, particularly in food safety and quality enhancement.

High-pressure homogenization has enabled the efficient production of chitin nanofibers and the modification of biopolymers like Mamaku polysaccharide, allowing for tailored viscosity and texture in innovative food products.

Traditional homogenizers may struggle with materials that are viscoelastic or those requiring precise control over particle size distribution, which is why alternative technologies are being explored.

Ultra-high-pressure homogenization has the potential to enhance the technofunctional properties of ingredients like microcrystalline cellulose, revealing broader applications across industries such as food and pharmaceuticals.

Industries can benefit from advancements in shear homogenizer technology by improving efficiency, sustainability, and the quality of their products, leading to better outcomes in applications ranging from food to pharmaceuticals.

So, I recently came across a blog titled "The Future of Shear Homogenizers in Achieving Ultra Fine Particle Dispersion," and honestly, it’s pretty interesting. It dives into how shear homogenizers are really pushing the boundaries when it comes to nanoemulsion tech, especially in making formulations more stable and giving them that nice, smooth texture we’re after. The article also compares these traditional homogenizers with newer alternatives that are popping up—seems like industry folks are leaning more toward high-efficiency models that can really break down particles more effectively.

What caught my eye was the discussion on whether these high-tech machines are worth the investment compared to other methods. It’s clear they add a lot of value in boosting productivity, especially in fields like pharma. Plus, there are some real-world examples and case studies that show how shear homogenization makes a difference in drug formulations. And, of course, it hints at some exciting innovations on the horizon—who knows what new applications we’ll see in material science!

By the way, CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, a major player in high-pressure homogenization, really emphasizes how crucial shear homogenizers are in developing cutting-edge nanotech solutions tailored for all kinds of industries. It’s pretty clear they see these tools as key players moving forward.