In today’s food and beverage world, homogenizers are pretty much a game-changer when it comes to keeping products consistent, stable, and high quality. Did you know that according to recent market reports, the global market for food homogenizers is expected to hit around 1.2 billion USD by 2025? That’s pretty impressive, and it’s growing at about 5.3% CAGR. Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are really leading the way with these tools. They’re essential for stuff like emulsifying ingredients or reducing particle sizes, which makes foods and drinks taste better and have a better texture.

Thanks to new tech like nanotechnology and high-pressure homogenizers, producing smooth, uniform mixtures has gotten way easier. This means brands can meet customer expectations for really top-notch products. As manufacturers keep tweaking and improving their processes to stay competitive and adapt to market trends, using homogenizers strategically is gonna be super important for coming up with new and exciting products—and just staying ahead of the game.

Thanks to new tech like nanotechnology and high-pressure homogenizers, producing smooth, uniform mixtures has gotten way easier. This means brands can meet customer expectations for really top-notch products. As manufacturers keep tweaking and improving their processes to stay competitive and adapt to market trends, using homogenizers strategically is gonna be super important for coming up with new and exciting products—and just staying ahead of the game.

Homogenizers are pretty essential when it comes to making sure things like food and drinks turn out just right. Basically, they help make the texture and ingredients look and feel consistent across the board. The main job of a homogenizer is to break down bigger particles—think fat globules or solid bits—into much smaller, more uniform pieces. Doing this helps create a stable mixture, which is super important for dairy products like milk and cream. Without it, you might end up with separation or spoilage, which nobody wants.

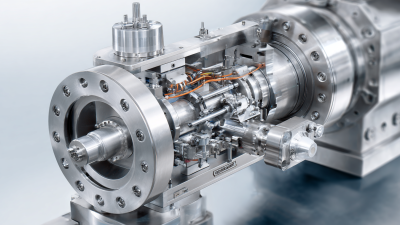

So, how does it work? Well, it uses high-pressure pumps that push the mixture through a tiny opening or some sort of narrow gap. That forces the mixture to go through a lot of shear and turbulence, which sounds fancy, but basically means the particles get smashed and spread out evenly. This process doesn’t just make the product look better and feel nicer in your mouth, but it also helps it last longer on the shelf by preventing separation. Plus, because the particles are more uniform, the flavor tends to come through more consistently—making the final product even more appealing for us consumers.

In today’s world of food and drink production, homogenizers are pretty much essential for making sure your beverages come out consistent and high quality. These machines use some pretty advanced shear tech—basically combining homogenization with ultra-high pressure—to not only give the drink that smooth, uniform texture but also to boost safety by killing off bacteria effectively. It’s kind of like pasteurization or sterilization; here, the right temperature and how long you apply it really make all the difference in wiping out bacteria.

Here’s a little tip for folks in manufacturing: watch those operation settings closely. Tweaking the pressure and temperature just right can seriously impact how good and safe your final product turns out. Also, don’t forget regular maintenance on those homogenizers—they need to be clean and functioning well if you want consistent results and to avoid any nasty contamination issues.

Another handy tip is to test the product regularly after homogenization. It’s a good way to double-check that your process is working properly—making sure you’re hitting the right texture and safety standards. If you adopt these practices, your beverage company can really make the most of homogenization tech, boosting product quality, staying on top of regulations, and making your customers happy all around.

| Application | Homogenizer Type | Benefits | Typical Products |

|---|---|---|---|

| Emulsification | High-Pressure Homogenizers | Improves texture and stability of emulsions | Dressings, sauces, and spreads |

| Particle Size Reduction | Ultrasonic Homogenizers | Enhances mouthfeel and uniformity | Smoothies and juices |

| Cream Separation | Rotary Homogenizers | Produces consistent cream qualities | Dairy products like milk and cream |

| Microbial Reduction | Colloid Mill Homogenizers | Increases safety and shelf-life | Juices and dairy |

| Blending | Batch Homogenizers | Ensures uniform ingredient distribution | Smoothies, drinks, and soups |

Homogenizers are pretty important in the dairy world, especially when it comes to processing milk and cream. Basically, they use high pressure to break down those fat globules into much smaller pieces, which helps create a stable mixture. This not only makes the dairy feel and taste better—giving it a nice smooth texture—but also helps it last longer since it keeps the cream from separating out. The end result? A consistent, high-quality product that customers love and expect.

Homogenizers are pretty important in the dairy world, especially when it comes to processing milk and cream. Basically, they use high pressure to break down those fat globules into much smaller pieces, which helps create a stable mixture. This not only makes the dairy feel and taste better—giving it a nice smooth texture—but also helps it last longer since it keeps the cream from separating out. The end result? A consistent, high-quality product that customers love and expect.

Now, if you're thinking about choosing a homogenizer for your dairy operation, there are a few things to keep in mind. Think about what fat content you want in the final product, how much you’ll be processing, and how easy it is to maintain the equipment. A good homogenizer should work efficiently, save energy, and not wear out too quickly. And don’t forget, regular upkeep is key to keep things running smoothly and to make sure your investment lasts.

Homogenizers aren’t just for milk and cream—they’re also used in making other dairy goodies like yogurt and cheese. They help ensure a consistent quality and smooth texture, which really boosts how appealing these products are on the shelf. As more folks are looking for top-notch dairy products, having a solid homogenization process becomes super important in today’s food and beverage industry.

Homogenizers really are a game-changer when it comes to boosting the flavor and texture of sauces and dressings. Honestly, they’re pretty much a must-have in today’s food and drink production. When you use a homogenizer, it ensures everything gets blended into a really smooth, uniform mixture — which is key for getting that perfect viscosity everyone loves. And let’s be honest, the way a sauce or dressing feels in your mouth totally affects how you perceive its flavor. A well-homogenized product just tastes more balanced, with all the ingredients coming together nicely, and it gives that consistent mouthfeel we all expect.

Homogenizers really are a game-changer when it comes to boosting the flavor and texture of sauces and dressings. Honestly, they’re pretty much a must-have in today’s food and drink production. When you use a homogenizer, it ensures everything gets blended into a really smooth, uniform mixture — which is key for getting that perfect viscosity everyone loves. And let’s be honest, the way a sauce or dressing feels in your mouth totally affects how you perceive its flavor. A well-homogenized product just tastes more balanced, with all the ingredients coming together nicely, and it gives that consistent mouthfeel we all expect.

If you wanna get that ideal thickness, a good tip is to play around with the temperature of your ingredients beforehand — warmer temps can make blending way easier. Also, trying out different emulsifiers can help keep the mixture stable, so flavors stay fresh and intact over time. Don’t forget to keep an eye on the shear rate during homogenization because it really impacts the final texture.

Long story short, using homogenizers thoughtfully can turn your everyday sauces and dressings into something that feels fancy and impressive, not to mention making them look great and taste even better — exactly what modern consumers are after.

Homogenization is honestly a game-changer in today’s food and beverage world. It really helps boost product quality and makes the whole eating experience a lot better for us consumers.

One of the biggest perks? It helps products last longer on the shelf. When fats are broken down into tiny, uniform globules, it stops the ingredients from separating and keeps spoilage at bay. That’s why things like milk or salad dressings stay fresh longer — super important for stores and brands.

Plus, homogenization makes products more stable and appealing. When ingredients are evenly mixed, the emulsion looks better—it’s not all separated and weird-looking. It also means the taste and texture stay consistent, which we all appreciate. And here’s a neat bonus — it can actually boost the nutritional value of foods by making some nutrients easier for your body to absorb.

All in all, homogenization is pretty much essential for keeping our food better, healthier, and more enjoyable.

You know, the way homogenizer technology has evolved really changed the game when it comes to making food and drinks. These days, new innovations have made processing a lot more efficient, which means better quality products that are safe and consistent. Modern homogenizers now use some pretty advanced tech, like high-pressure systems and ultrasound, to get those super fine emulsions and suspensions. And honestly, that makes a big difference—not just in how the food feels and tastes, but it also helps products last longer by slowing down microbial growth.

Looking ahead, it seems like automation and smart controls are going to be the next big thing. Imagine machines that can monitor and tweak things on the fly—that’s the dream, right? It’ll cut down on human errors and make the whole process smoother and greener. Oh, and with more people asking for natural and organic stuff, researchers are working on new homogenization methods that protect raw ingredients’ natural qualities without messing with how they work. So, staying innovative is going to be key for manufacturers who want to keep up with what consumers are looking for—while juggling all the challenges in this industry, too.

: Homogenizers ensure consistency and quality in beverages by utilizing advanced shear technology to create a uniform texture and enhance product safety through effective bacterial destruction.

By effectively killing bacteria during the homogenization process, homogenizers enhance beverage safety, comparable to pasteurization and sterilization methods.

Manufacturers should optimize pressure and temperature settings during homogenization, as these significantly affect the final product's quality and safety.

Regular maintenance ensures homogenizers operate efficiently, preventing contamination and ensuring a consistent output in beverage production.

Homogenizers break down fat globules into smaller sizes to achieve stable emulsions, improving texture, mouthfeel, and shelf life of dairy products.

Considerations include the desired fat content in the finished product, processing volume, and maintenance requirements of the equipment.

Homogenization extends shelf life, enhances stability by preventing separation of components, and improves the nutritional value by increasing the bioavailability of certain nutrients.

It creates a stable emulsion that keeps ingredients evenly dispersed, resulting in a consistent taste and texture, which enhances consumer satisfaction.

Homogenizers are also used in the production of yogurt and cheese, ensuring consistent quality and stable texture.

As consumer demand for high-quality dairy continues to rise, effective homogenization processes are crucial for meeting those expectations and improving product appeal.

Hey, have you ever thought about just how important homogenizers are in today’s food and beverage industry? I was reading this article called "Exploring the Essential Uses of Homogenizers in Modern Food and Beverage Production," and it really got me thinking. It talks about how these machines do more than just mix stuff—they actually play a key role in making our drinks and food products more consistent and tasty. For example, they help create uniform beverages and boost the flavor and texture of things like sauces and dressings. In dairy, they're pretty much indispensable, making sure milk and cream are processed smoothly. Oh, and they do a lot more: they improve shelf life, keep everything stable, and even boost nutritional value. It’s exciting because with all the new tech coming out, future homogenizers are only going to get better, making food production even more efficient and high-quality.

By the way, CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is all about this—they specialize in high-pressure homogenizers and microfluidizers, offering top-notch nanotech solutions that meet all sorts of needs across different industries. Basically, they're helping push the boundaries of how good our food can get, thanks to these incredible machines.