In today’s really competitive business world, picking the right equipment isn’t just a good idea — it’s absolutely key to keeping your production running smoothly, especially in industries that rely on homogenization technology. If you’ve been following industry trends, you probably know that the global market for homogenizers is expected to hit around $1.5 billion by 2025. A big driver behind this? The rising demand for small homogenizers that can produce consistent particle sizes and better product stability — whether we're talking about pharmaceuticals, food, or beverages. At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about high-pressure homogenizers and microfluidizers, offering innovative nanotech solutions that are tailored to meet these needs. Honestly, really understanding what makes small homogenizers tick is super important if you want to boost your product quality and overall efficiency. Making the right choices here can make all the difference for your business’s success.

When you're on the hunt for a small homogenizer for your business, there are actually a few key things you should keep in mind to make sure it works well and runs smoothly. First off, you wanna get a clear idea of how much processing capacity you need. I read a recent market report from Grand View Research that says the global homogenizer market is expected to hit around $4.25 billion by 2025. Interestingly, there’s a lot of focus on smaller-scale setups, especially in industries like pharma and food processing. That makes sense because more and more companies want machines that can handle smaller batches without sacrificing quality.

Another important thing to think about is how flexible the homogenizer really is—like, can it work with all sorts of materials? Having a machine that’s versatile not only opens up more options but also makes your life easier. A survey from Research and Markets showed that over 60% of businesses say they want homogenizers that can handle different viscosities. So, picking a model that has adjustable pressure settings and different rotor-stator options can really make a difference in what you can produce and how efficiently you do it. Also, don’t forget to check out how easy it is to maintain and operate the machine—this stuff might sound small, but it can save you a lot of headaches and downtime in the long run.

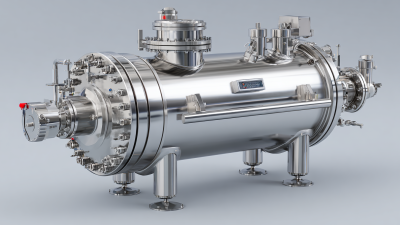

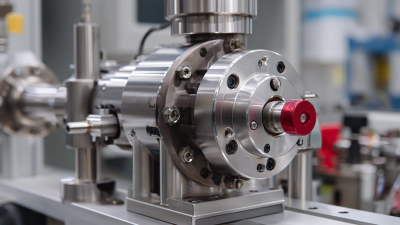

When you’re trying to pick out the perfect small homogenizer for your business, it’s really helpful to get a sense of the different types out there and what they’re good for. For example, high-pressure homogenizers, or HPHs, have been gaining popularity lately. That’s mainly because they do a great job of preserving liquid foods without needing heat, using mechanical forces instead. This helps improve the texture and stability of your products, all while keeping nutrients intact. If your project involves creating emulsions or breaking down cells mechanically, then centrifugal homogenizers might be the way to go. They use centrifugal force to mix stuff effectively and reduce particle size, which works really well for various emulsification tasks.

As you make your choice, here are some tips to keep in mind. First, think about the size of your operation — some homogenizers are better for small batches, while others can handle larger volumes. Next, check whether the materials you’ll be working with are compatible with the machine — especially if you’re dealing with sensitive biological samples. And lastly, consider where you want your business to go in the future. Picking a versatile homogenizer that can grow with you is a smart move. Understanding these points will help you make a decision that really fits your specific needs and applications.

When it comes to making sure your products come out consistent every time, homogenization really plays a key role. Even a small homogenizer can be a total game-changer for businesses that want their sauces, creams, or drinks to look and feel the same across batches. Basically, it breaks down particles and creates a stable mixture, so each product ends up with the same texture, look, and flavor. That’s super important—not only because it meets what customers are expecting, but also because it helps build trust and loyalty. People tend to stick with brands they know they can rely on for quality.

On top of that, investing in a good small homogenizer can really boost your overall production process. If the homogenization isn’t done properly, ingredients might separate, which ruins the quality and even shortens the shelf life. So, it’s worth taking the time to look at things like the machine’s capacity, pressure options, and how precise it is. Picking the right one that performs well means you can keep your product consistent, stay compliant with regulations, and ultimately keep your customers happy—leading to better sales and a stronger brand.

In a nutshell, good equipment makes a huge difference, and finding the right homogenizer is a smart move for any business serious about quality.

When you're trying to pick out a small homogenizer for your business, it's really important to find that sweet spot between price and performance. Industry reports show that investing in a decent homogenizer can seriously boost your product quality and streamline your operations. I read a recent market analysis by Mordor Intelligence, and it said that the global market for homogenizers is expected to grow at about 5.8% annually from 2021 to 2026. This is mainly because more sectors like food and drinks, pharma, and cosmetics are demanding better equipment. So, it’s a clear sign that businesses need to choose wisely — weighing the initial costs against the long-term benefits in performance.

Now, when it comes to costs, things get a bit tricky. Sure, a cheaper homogenizer might seem tempting at first, but studies show that how durable and efficient a machine is can really impact your overall expenses in the long run. A report from Food Processing Technology pointed out that high-performance homogenizers can cut processing times by up to 30%. That means you might end up saving money on energy and even offset that higher initial price. Plus, investing in a reliable machine means your products stay consistent in quality, which makes your customers happier and more likely to stick around. And that, in turn, can really boost your sales and profits. So, finding that perfect balance — between cost and what you get in return — is key to making sure you choose a small homogenizer that gives you the best bang for your buck.

If you're thinking about investing in a small homogenizer for your business, it’s really important to get a handle on how maintenance and support play into its longevity and performance. Regular check-ups can actually save you a lot of headaches down the road—think less downtime and fewer costly repairs. Honestly, setting up a routine inspection schedule and keeping a log of whatever service gets done is a pretty good idea. And don’t forget, working with a dependable supplier who can offer advice and support is a game-changer. They can help you catch potential issues early on before they turn into bigger problems.

Aside from just routine maintenance, picking a homogenizer that comes with solid customer support can really make your life easier. Always ask about the warranty and whether spare parts are readily available before pulling the trigger on a purchase. Having a good support system means you can troubleshoot quickly if anything goes wrong, which keeps your production running smoothly without unnecessary hiccups.

When you’re choosing the right homogenizer, think about features like how easy it is to clean and maintain. A model that’s simple to disassemble can save you a bunch of time during regular upkeep. Plus, gadgets with user-friendly interfaces and clear instructions just make everything less stressful—less chance for mistakes that mess up your efficiency.

The small homogenizer market is really heating up right now, with tons of exciting innovations popping up. Thanks to advances in technology and the growing need for better efficiency and precision in various industries, things are changing fast. I recently came across a report by MarketsandMarkets saying that by 2027, the global small homogenizer market could hit around $1.5 billion—pretty impressive! It’s mainly driven by the booming demand for top-notch emulsions and dispersions in sectors like pharma, food and drinks, and cosmetics.

Picking out the right small homogenizer for your business? That’s an important step. First off, think about what materials you'll be working with. Tip #1: Check the viscosity of your products. Different homogenizers are built to handle different thicknesses, which actually impacts how well your emulsions turn out. Also, it’s a good idea to go for a machine with adjustable shear rates—it makes your setup way more flexible for different tasks.

Another trend worth mentioning is how many newer models are focusing on energy efficiency and reducing waste. Tip #2: Look for homogenizers that have smart tech features—things like real-time monitoring and automatic adjustments. They help you get the best performance while saving energy. Since sustainability is becoming such a big deal these days, choosing a machine that aligns with eco-friendly practices not only keeps your business ahead of the competition but also helps you do your part for the environment."

| Feature | Importance | Considerations |

|---|---|---|

| Size & Capacity | Ensure it fits your production needs | Evaluate batch sizes and processing times |

| Homogenization Technique | Affects the quality of the final product | Consider high-pressure vs. ultrasonic methods |

| Material Compatibility | Prevents contamination of products | Identify compatible materials with your samples |

| Ease of Use | Reduces training time for staff | Look for intuitive controls and user-friendly design |

| Maintenance & Support | Ensures long-term functionality | Check availability of repairs and spare parts |

| Energy Efficiency | Reduces operational costs | Consider power consumption ratings |

| Price | Aligns with budget constraints | Compare features against cost |

: The main types of small homogenizers include high-pressure homogenizers (HPHs) and centrifugal homogenizers. HPHs are effective in preserving liquid foods, while centrifugal homogenizers are suitable for emulsification and mechanical cell lysis.

High-pressure homogenizers use mechanical forces to enhance the stability and texture of products, effectively preserving them without thermal treatment while minimizing nutrient loss.

Centrifugal homogenizers are ideal for emulsification processes and mechanical cell lysis, utilizing centrifugal force for effective mixing and particle size reduction.

Key factors include the scale of operations (low-volume vs. large batch production), material compatibility (ability to process various substances), and future scalability (flexibility to adapt to changing production needs).

Assess both upfront costs and long-term performance benefits. Consider durability and efficiency, as a higher-performing unit may reduce processing time and lower operational costs over time.

Investing in a reliable homogenizer ensures consistent product quality, which can enhance customer satisfaction and loyalty, ultimately contributing to higher sales and profitability.

The global homogenizer market is projected to grow at a CAGR of 5.8% from 2021 to 2026, driven by increasing demand in the food and beverage, pharmaceutical, and cosmetic sectors.

While lower-priced homogenizers may seem appealing, they can lead to higher overall operational costs due to durability and efficiency issues. A higher initial investment may be offset by lower processing times and energy expenses.

Trying to find the perfect small homogenizer for your business? It’s not just about picking any machine — there are a few key things you really should keep in mind. First off, understanding the different types of small homogenizers out there and what they’re best suited for can make a huge difference. After all, good homogenization isn’t just about mixing — it’s about ensuring your product stays consistent, which totally impacts customer satisfaction and keeps your brand reliable. Then, of course, you want to weigh the costs against what you'll actually get in terms of performance. Finding that sweet spot between a solid initial investment and long-term benefits is crucial. Oh, and don’t forget, maintenance and support aren’t just afterthoughts — they play a big role in making sure your equipment lasts and runs smoothly over time.

At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re pretty much experts when it comes to high-pressure homogenization and microfluidization solutions, catering to a range of industries. As you dig into the latest trends and new tech in small homogenizers, teaming up with folks like us could really help you cut through all the options and zero in on what’s best for your specific needs. We’re here to make sure you get the right setup so your business keeps moving forward without a hitch.