The booming cannabis scene these days absolutely emphasizes the need for consistent product quality and better extraction methods—it’s more important than ever. One of the game-changers? Homogenizers for cannabis. They really help improve the extraction process and make sure the final products turn out uniform and reliable.

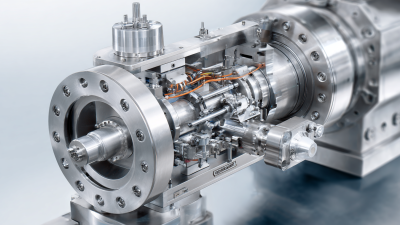

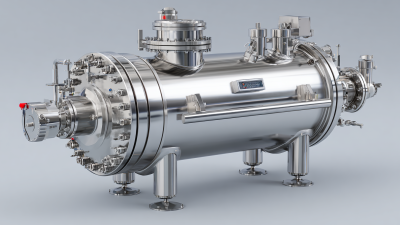

Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about high-pressure homogenizers and microfluidizers designed for all sorts of uses, including cannabis extraction. Our focus on cutting-edge nanotech means we’re well-equipped to meet the unique needs of the cannabis industry, helping producers deliver products with consistent potency and quality.

In this blog, we’ll dive into how to effectively use homogenizers in cannabis extraction—covering some best practices and cool tech tricks that can boost your product’s quality and make your operations smoother and more efficient.

Homogenizers are pretty essential when it comes to extracting cannabis oils. They really help make the product more consistent and high-quality. In the cannabis world, getting a precise extraction is super important, and that's where homogenizers come in—they use mechanical force to ensure the particles are uniform in size and evenly spread out. I read in the Cannabis Business Times that using high-shear homogenization can boost extraction efficiency by as much as 30%. That means producers can get more oil out of their plants without sacrificing potency or purity, which is a big win.

On top of that, homogenizers help keep cannabis emulsions stable—that’s totally critical when making edibles, topicals, or any infused products. According to the Journal of Natural Products, when particle sizes are consistent thanks to homogenization, cannabinoids become more soluble and bioavailable across different formulations. As brands keep pushing to meet regulatory standards, adopting advanced homogenization techniques not only ups the quality of their products but also makes sure each batch turns out just right. That kind of consistency is key for building trust with customers and maintaining a solid reputation in this fast-moving cannabis scene.

Using homogenizers in cannabis extraction? Honestly, it’s a game-changer. They do a great job of making sure your products are consistent, which is super important. I read in the Cannabis Science and Technology report that having an even spread of cannabinoids really matters—whether you're dosing or aiming for specific therapeutic effects. Homogenizers help break down particles to tinier sizes and stabilize emulsions, so each batch ends up pretty much the same. As more folks get into edibles and oils, keeping that texture and potency uniform isn’t just a nice bonus—it’s essential for building trust with your customers and keeping your brand solid.

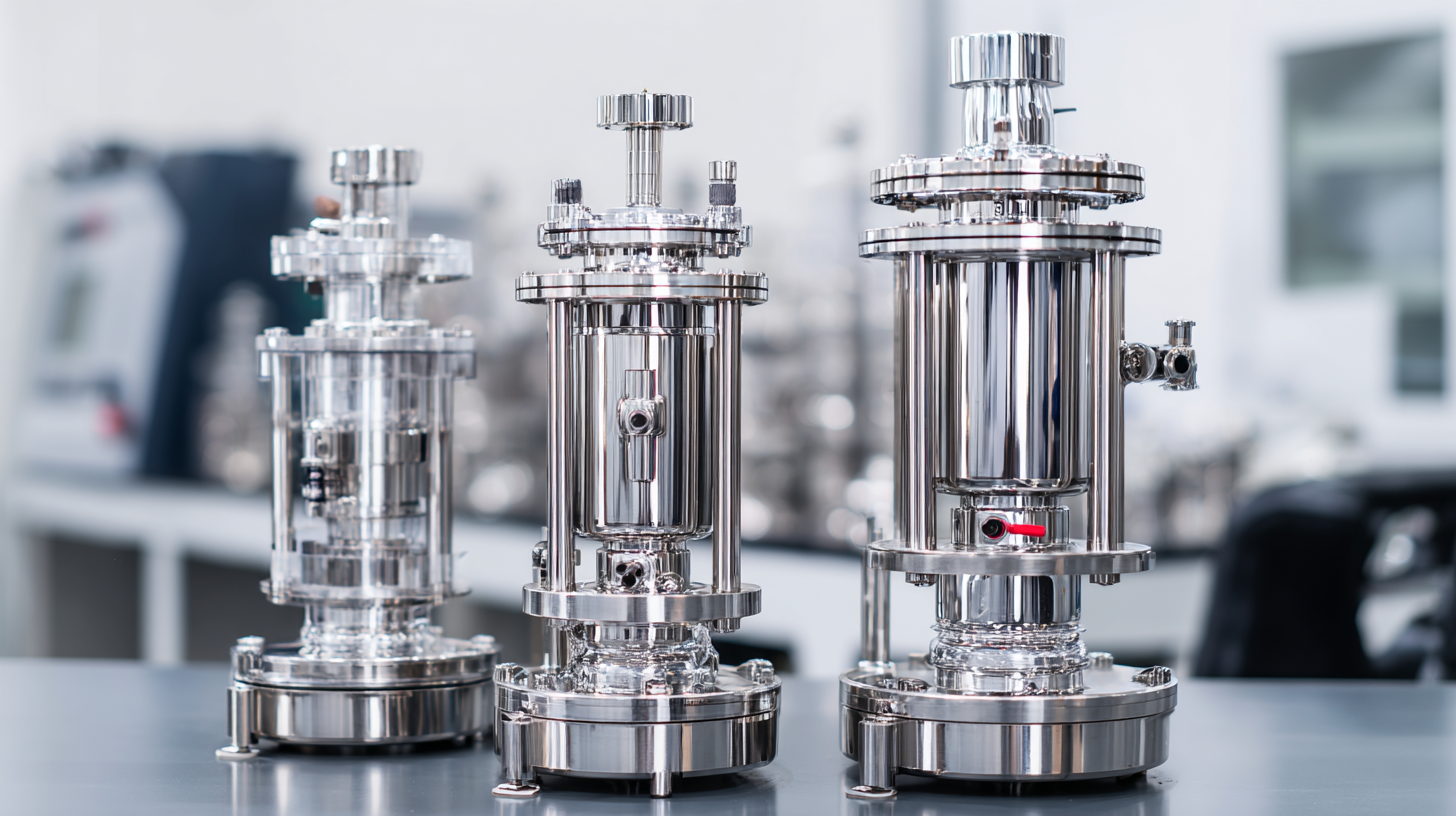

When you're picking a homogenizer, think about the size of your operation. If you’re just a small-scale producer, a bench-top model might do the trick. But if you're running a larger operation, then you probably need an industrial-grade machine to keep up with the demand.

Oh, and here’s another thing—temperature and processing time really do matter. They affect the final quality, especially the bioavailability of cannabinoids, so your customers actually get the effects they’re looking for. Plus, using high-shear homogenization techniques can give you finer emulsions, which is especially crucial for water-soluble cannabis products.

**Pro tip:** Play around with your homogenization settings—like speed and how long you run it—to get just the right consistency and potency. And don’t forget, regular calibration and maintenance of your equipment can seriously improve the uniformity of your extracts, cutting down on variability and making sure your products turn out as intended.

When it comes to extracting stuff from cannabis, folks have been sticking with traditional methods like solvent extraction, CO2 extraction, and steam distillation for ages. Honestly, these processes can be pretty time-consuming and sometimes tricky, with things like temperature swings or pressure tweaks leading to inconsistent results. Plus, there’s always the risk of residual solvents hanging around, which isn’t ideal since everyone wants a pure product. That’s a big deal because both producers and consumers care a lot about quality and consistency, right?

On the flip side, newer methods like homogenization are kind of changing the game. Using high-shear mixing or ultrasonication, these techniques can break down plant material efficiently—no need for nasty solvents that can cause issues. Not only do they speed things up, but they also help make sure the active compounds, like cannabinoids and terpenes, are evenly spread throughout the product. And because you can control things like time and energy input pretty precisely, the results tend to be much more consistent—sort of a big win in the constantly changing cannabis scene. Getting what’s better between these two approaches can really make a difference in the quality and reliability of the products people buy and enjoy.

When it comes to cannabis extraction, using a homogenizer really makes a difference in getting consistent products and squeezing out the most from your plant material. There are a few key settings you need to dial in to do it right—things like how fast you run the homogenizer, how long you process, and what solvent you choose. All these little details add up and really affect things like potency and flavor.

For example, the speed can be a bit tricky. Cranking it up might make the particles smaller, which helps pull out more cannabinoids and terpenes. But if you go too fast, you risk heating things up—heat that could actually break down the very compounds you're trying to preserve. So, finding that sweet spot is super important. Then there's the processing time. Too long and you might overdo it, leading to weird extraction results. And of course, picking the right solvent is crucial for keeping the active ingredients intact while still getting a good extraction. When all these parameters are tweaked just right, the homogenizer becomes a powerful tool for creating high-quality cannabis products that meet your desired standards.

| Parameter | Optimal Range | Impact on Extraction | Notes |

|---|---|---|---|

| Temperature (°C) | 20-60 | Affects solubility of compounds. | Higher temperatures may degrade some cannabinoids. |

| Pressure (psi) | 500-3000 | Increases cell rupture efficiency. | Careful control is required to avoid emulsification. |

| Time (minutes) | 5-30 | Longer times generally improve extraction yield. | Monitor for signs of thermal degradation. |

| Solvent Type | Ethanol, CO2, Olive Oil | Affects solubility and extraction efficiency. | Choose solvent based on desired compound profile. |

| Sample Size (g) | 5-50 | Larger samples may require longer processing. | Ensure uniform particle size for consistent results. |

When it comes to extracting cannabis, making sure the product turns out consistent is super important, and how well you homogenize really makes a big difference. Industry folks always say that using good quality homogenizers is key — this helps keep the particle distribution even throughout the extract. That evenness isn’t just about looks; it actually boosts how potent and effective the final product is, and it helps users get a consistent experience every time they use it.

So, when you're picking a method for cannabis homogenization, it's all about matching the equipment to your production size and the specific kind of extract you’re working with. For example, high-shear homogenizers are great if you want to shrink particles down and make your emulsion more stable. Also, don't forget that regularly maintaining and calibrating your equipment is a must — it keeps everything running smoothly and ensures you meet those industry standards. Plus, paying attention to things like temperature and pressure during the process can really make or break the quality of your extract. Stick to these tips, and you'll be able to keep delivering top-notch cannabis products that tick all the boxes — for both regulators and your customers alike.

: Homogenizers play a crucial role in cannabis oil extraction by enhancing product consistency and quality, achieving uniform particle size and distribution, and significantly improving extraction efficiency.

High-shear homogenization can improve extraction efficiency by up to 30%, which helps producers maximize yield while maintaining potency and purity.

Homogenizers contribute to the stability of cannabis emulsions, which is vital for creating infused products like edibles and topicals, ensuring better solubility and bioavailability of cannabinoids.

Traditional extraction methods, such as solvent extraction and CO2 extraction, often have lengthy processes and inconsistencies, whereas homogenization techniques provide a more efficient and consistent extraction without the use of corrosive solvents.

Homogenization techniques enhance extraction efficiency, ensure uniform distribution of active compounds, and allow for precise control over parameters for repeatable results, leading to greater product consistency.

By enhancing product quality and ensuring batch-to-batch consistency, advanced homogenization techniques help build consumer trust and uphold brand integrity in the rapidly evolving cannabis market.

Traditional extraction methods can leave behind residual solvents that compromise product purity and may result in inconsistencies due to variations in temperature, pressure, or solvent application.

Consistent particle size obtained through homogenization fosters better solubility and bioavailability of cannabinoids, which is crucial for effective product formulation.

Homogenizers are pretty pretty important when it comes to processing cannabis, especially if you wanna get consistent and efficient extraction of cannabis oil. Basically, by using high-pressure homogenizers, manufacturers can break down the particles more evenly and create a nice, stable emulsion. That means your final product is not only more reliable but also packs a punch in terms of quality. Compared to the older, more traditional extraction methods, homogenization really steps up the game — you'll see better yields and a better overall product, which is, of course, super important to meet industry standards.

But here’s the thing: getting the best results from cannabis homogenization isn’t just about using the equipment. You’ve got to fine-tune things like pressure, temperature, and how long you treat the mixture. Small tweaks here and there can make a huge difference in how consistent everything turns out.

Oh, and by the way, CAS PETER (Hangzhou) Nanotechnology Co., Ltd. specializes in high-pressure homogenizers and microfluidizers that are tailored for the cannabis world. They make sure you get the best extraction results possible, all while following industry best practices. Pretty cool, right?