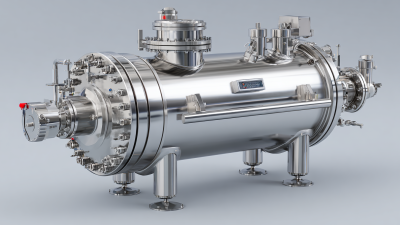

High pressure homogenizers are pretty much essential tools when it comes to breaking down cells, and they play a crucial role across various industries—things like pharma, biotech, and food processing. From what I’ve seen in recent reports, the global demand for high-pressure homogenization tech is set to skyrocket. That’s mainly because there’s a growing need for more efficient ways to lyse cells, which helps extract those valuable biomolecules more effectively.

CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is really into researching and selling these high-pressure homogenizers and microfluidizers, offering innovative nanotech solutions that fit a wide range of needs. Knowing how to properly use a high-pressure homogenizer for cell disruption isn’t just about boosting yields; it’s also about consistently getting high-quality results. As industries move toward more advanced bioprocessing methods, getting a good grip on how high-pressure homogenization works is more important than ever for both researchers and manufacturers alike.

You know, high-pressure homogenization (or HPH, for short) has really become a game-changer across a bunch of industries, especially when it comes to food safety and keeping products fresh. Basically, it works by quickly pressurizing stuff and then releasing that pressure suddenly — which breaks down particles into much smaller sizes and boosts how molecules interact with each other. What’s cool is that, by using this non-thermal method, food producers can improve the stability of their products and extract key phytochemicals more efficiently. That means more nutrition packed into your food, all while keeping it safe. Recently, researchers have been noticing that HPH does a really great job at pulling out bioactive compounds, helping our bodies absorb and use them better — sounds pretty promising for biomedical uses, right?

The way HPH actually works is pretty interesting — it basically tears apart cell walls and microbes, leading to a more uniform and consistent product. Studies show that it doesn’t just help preserve liquid foods; it also boosts the quality of emulsions by cutting down microbial contamination. Plus, HPH can make nutrients more bioavailable and deactivate harmful microorganisms, which really adds value to what we eat.

At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, they’re all about creating cutting-edge high-pressure homogenization solutions tailored to help industries meet their evolving needs for better safety and effectiveness — pretty cool, huh?

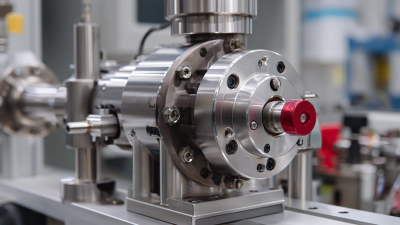

When it comes to high-pressure homogenization (or HPH for short) for breaking open cells, a bunch of factors really matter and can totally change how well the process works. First off, the pressure you apply is super important—cranking it up generally helps tear down the cell walls more effectively, releasing all those valuable bits inside. But it’s not just about pressure—things like the design of the homogenizer nozzle and the gap width also make a difference. They influence the shear forces on the cells, so tweaking them can mean the difference between good recovery and missed targets.

Then, there are the processing conditions—like temperature and flow rate—that play a big role too. Heating things up can help solubilize biomolecules, making extraction easier, but if it gets too hot, it might mess with sensitive proteins and cause denaturation (not ideal!). On the flip side, controlling the flow rate ensures cells stay in the right amount of contact with those forces, making cell rupture more efficient. All in all, nailing down these parameters — and balancing them just right — is key to maximizing the extraction of stuff like proteins and lipids from microalgae and microbes. That way, we can really push forward with sustainable biorefinery approaches, turning these tiny organisms into valuable resources.

Lately, high pressure homogenization, or HPH for short, is really getting a lot of attention for its pretty impressive results across a bunch of different applications. If you’ve read up on recent studies, you’ll notice that HPH often comes out on top when it comes to stabilizing emulsions—better than the old-school methods we used before. For example, there’s research showing that pectins extracted using high hydrostatic pressure actually do a better job at stabilizing emulsions compared to pectins made through traditional heat processing or high-speed shear techniques. And when it comes to whey protein-stabilized emulsions, HPH seems to really make a difference in slowing down oxidation, which basically means these emulsions stay fresher longer—making them more shelf-stable.

On top of that, there’s been some interesting head-to-head comparisons between HPH and antisolvent precipitation techniques for making nanosized particles of drugs like amphotericin B. Turns out, HPH doesn’t just produce a more uniform particle size distribution; it also helps boost the bioavailability of the drug—so it works better in the body. Thanks to the specific conditions involved with high pressure homogenization, scientists can tweak the properties of the final product pretty precisely, which explains why it’s such a popular choice for both foods and medicine formulations. As more and more innovative products are being developed, the versatility and proven efficiency of HPH really make it an important tool for pushing the boundaries of traditional homogenization methods.

High-pressure homogenizers are pretty powerful tools when it comes to breaking open cells, but getting the settings just right is key to making sure you get good lysis. The pressure and flow rate you choose really matter for how effective the process is. Cranking up the pressure can generate pretty intense shear forces, which usually means better cell disruption. But here’s the thing—pushing pressure too high might damage sensitive biomolecules, so it’s all about finding that sweet spot. I’d recommend trying out different pressure levels to see what works best for your specific cell type.

When it comes to flow rates, they really affect how long your samples stay inside the homogenizer. Going slower means your cells are exposed to shear forces longer, which can help break them open more effectively. On the flip side, running at a really slow rate might cause overheating, and that’s not great because it can hurt the cells or degrade your stuff. So, a good approach is to do some trial runs—start with a moderate pressure and gradually increase it, while paying attention to temperature. Make sure you’re cooling things down as needed to avoid thermal damage. Also, considering pre-treatments like enzymes or ultrasound can make the lysis process smoother and more efficient during homogenization.

**Tips:** Begin with a moderate pressure and bump it up slowly. Keep an eye on the temperature, and don’t be shy about adjusting your cooling setup. Oh, and experimenting with pre-treatments can really give you a leg up for better cell disruption during the process.

Switching from lab-scale to full-on industrial use of high-pressure homogenizers isn't just a simple jump — it takes some careful planning and considering a bunch of different factors. Recent studies highlight that when you're developing drugs, you really need to keep scalability in mind to make sure they’re commercially viable down the line. For example, using flash nanoprecipitation (FNP) to produce nanoparticles of poorly water-soluble drugs has become quite popular. Why? Because it allows for tight control over mixing and the size of those tiny particles, which is super important for making sure the drug works effectively. Whatever formulation you’re working on, thinking about how it will scale up should be part of the design process, helping to make the move from small pilot batches to larger production smooth sailing.

In nanomedicine, it's pretty much essential to use a mix of top-down and bottom-up manufacturing strategies if you want to get those nanoscale structures just right. A lot of small molecule drug candidates—something like 90%—end up suffering from poor solubility, which is a real headache. That’s why having strong manufacturing methods in place is so important. High-pressure homogenizers and microfluidizers, like the ones from CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, are key players here. They help produce lipid-based nanoparticles while keeping quality standards high. As industries lean more and more on cutting-edge manufacturing tech, figuring out how to optimize these homogenization processes will be crucial for tackling scalability issues and making these drugs ready for the market.

High-pressure homogenization is such a vital technique in the biopharma world, especially when it comes to breaking open cells effectively. There are quite a few real-world examples that show just how well it works. For example, when producing monoclonal antibodies, companies often use high-pressure homogenizers to burst mammalian cells efficiently. One particular case that sticks out involved a biotech firm that used this method to get higher concentrations of antibodies. By tweaking things like pressure and flow rates, they managed to break open cells better while keeping the proteins intact—that meant a better yield and purer antibodies overall.

High-pressure homogenization is such a vital technique in the biopharma world, especially when it comes to breaking open cells effectively. There are quite a few real-world examples that show just how well it works. For example, when producing monoclonal antibodies, companies often use high-pressure homogenizers to burst mammalian cells efficiently. One particular case that sticks out involved a biotech firm that used this method to get higher concentrations of antibodies. By tweaking things like pressure and flow rates, they managed to break open cells better while keeping the proteins intact—that meant a better yield and purer antibodies overall.

Then there’s the story about microbial fermentation. A research team applied high-pressure homogenization to disrupt yeast cells, which they’d harvested for making recombinant proteins. By carefully adjusting the process conditions, they were able to maximize cell lysis and pull out more of the target proteins. What’s pretty cool is that this way, they also cut down on unwanted by-products. These examples really highlight just how versatile high-pressure homogenizers are—such a powerful tool in biopharma, capable of boosting both product yields and process efficiency. It’s amazing how a bit of optimization can make such a difference, isn’t it?

: High-pressure homogenization is a non-thermal processing technique that reduces particle size and enhances molecular interaction, which is vital for improving the stability and extractability of essential phytochemicals in food products.

HPH improves the extraction and absorption of bioactive compounds, thereby enhancing the bioavailability of nutrients and increasing the efficacy of food products.

The effectiveness of cell lysis is influenced by pressure and flow rates. Higher pressures create stronger shear forces, while flow rates impact the residence time of samples in the homogenizer.

Excessively high pressures can lead to the degradation of sensitive biomolecules, which may negatively affect the quality of the final product.

Slower flow rates increase exposure time to shear forces, enhancing cell rupture; however, they may also lead to overheating and damage to certain cells.

Scalability considerations include formulation design, maintaining control over mixing and particle size, and ensuring smooth transitions from pilot batches to large-scale production.

Poor solubility affects approximately 90% of small molecule drug candidates. HPH facilitates the production of lipid-based nanoparticles, improving solubility and drug delivery.

They provide advanced high-pressure homogenization solutions that enhance the efficacy and safety of products, particularly for industries focusing on nanomedicine and drug formulation.

Temperature can be monitored and adjusted by implementing cooling options to prevent thermal damage to sensitive biomolecules during the process.

Enzymatic methods or ultrasound pre-treatment can facilitate a more effective lysis process when used prior to high-pressure homogenization.

High Pressure Homogenizers are pretty essential when it comes to breaking open cells—they rely on specific principles and mechanisms to do the job efficiently. If you get a good grasp of things like pressure and flow rates, you can really tweak and optimize how you run these machines to get the best results. When you compare them with other cell disruption methods, it’s clear that high-pressure homogenization has some big advantages, especially in fields like biopharmaceuticals, which is why it often ends up being the go-to choice.

Of course, moving from small lab setups to actual industrial-scale operations isn’t always straightforward, so planning and scaling up properly is super important for making sure everything works smoothly. There are plenty of case studies out there that show just how effective high-pressure homogenizers are—they really get the job done in terms of cell disruption.

Here at CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about offering advanced high-pressure homogenization solutions. We understand that every industry has different needs, so we’re committed to providing reliable, top-performing equipment that helps you achieve your goals with confidence.