Hey there! You know, in the fast-moving world of nanotechnology, finding efficient and precise ways to mix stuff is more important than ever — especially for industries like pharma, food and drinks, and cosmetics. Recent reports say the global market for high-pressure homogenizers could hit around $1.3 billion by 2025. That’s mainly because folks are coming up with new manufacturing techniques that need better emulsification and smaller particle sizes. If you're a manufacturer trying to bump up your product quality without sacrificing efficiency, investing in a Small Homogenizer might be the move you need.

At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about advanced high-pressure homogenizers and microfluidizers. We can tailor solutions to fit small-scale operations perfectly. Our goal? Helping businesses get top-notch results and stay ahead in this ever-evolving industry. We’re here to make sure you’re up to speed with the latest nanotech innovations!

Figuring out which homogenizer to go with is actually pretty important if you want to keep your manufacturing running smoothly. Especially in industries like food production or nanotech, knowing why homogenization matters can really make a difference in how good and consistent your products turn out. Take the dairy world, for instance—whether it’s making yogurt or soy milk, they use both traditional and newer homogenization methods to get that smooth, uniform texture and boost shelf life. The type of homogenization you choose can really change how small the particles are, which is a big deal for how fluids flow and stay stable in all sorts of recipes.

Figuring out which homogenizer to go with is actually pretty important if you want to keep your manufacturing running smoothly. Especially in industries like food production or nanotech, knowing why homogenization matters can really make a difference in how good and consistent your products turn out. Take the dairy world, for instance—whether it’s making yogurt or soy milk, they use both traditional and newer homogenization methods to get that smooth, uniform texture and boost shelf life. The type of homogenization you choose can really change how small the particles are, which is a big deal for how fluids flow and stay stable in all sorts of recipes.

When you're picking out a homogenizer, think about what you actually need for your project. Things like how thick your material is, and what kind of particle size you’re aiming for, are super important. And don’t forget—it's handy if the equipment can scale up easily, from small lab tests all the way to full-blown production.

For more advanced stuff, like working with cellulose nanofibers or lipid-based nanoparticles, the precision of your homogenization process becomes even more critical. Using high-pressure homogenization can really help create stable formulations that do exactly what you need them to do.

Pro tip: Try to get a homogenizer that’s versatile enough to handle different materials and processing needs. And it’s always a good idea to check particle sizes regularly—keeping an eye on quality control is key to making sure everything stays on point throughout your production process.

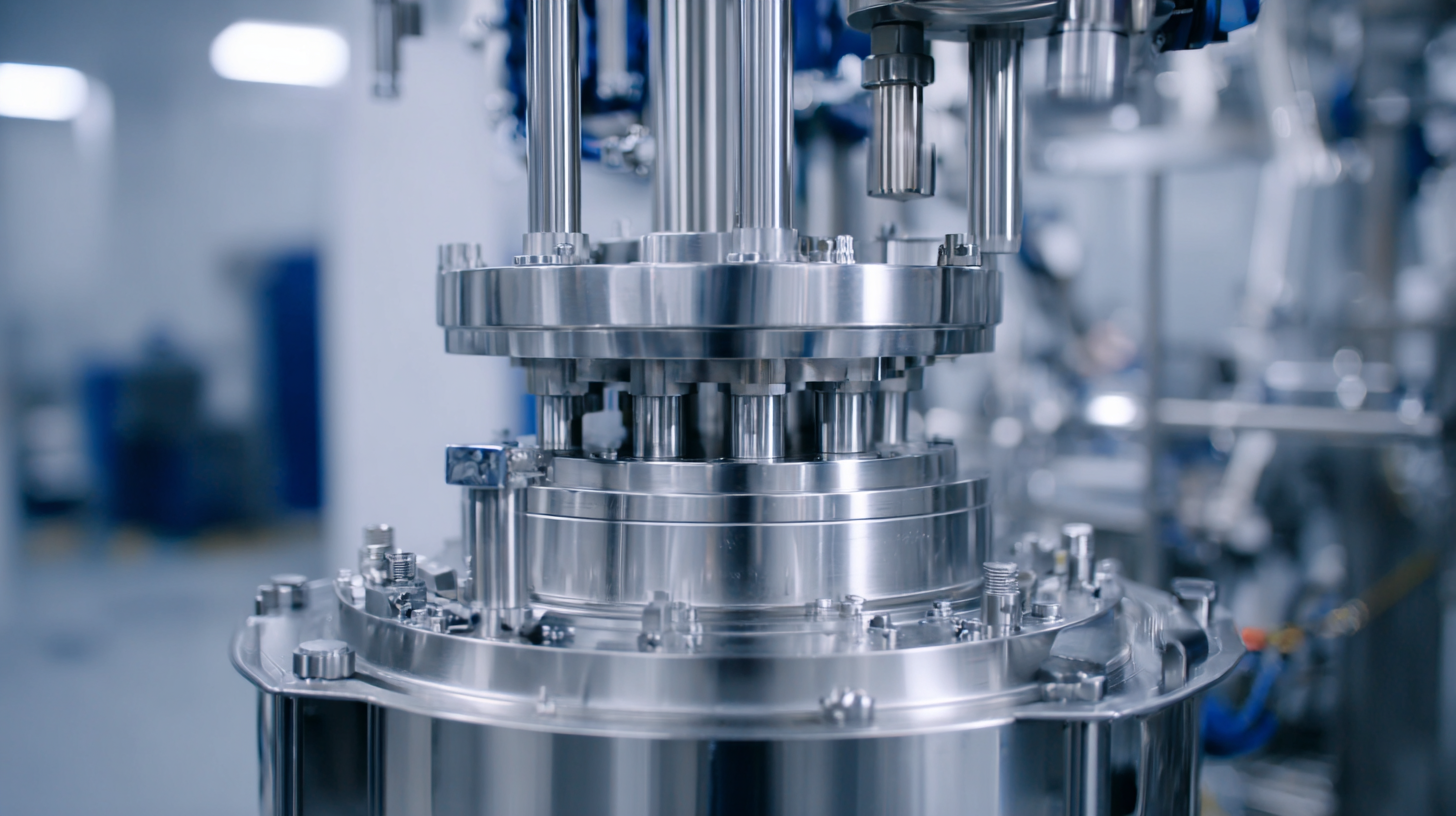

When you're on the hunt for a small homogenizer for your manufacturing setup, there are a few key specs you definitely don’t want to overlook. Power capacity, for example, is super important — most small units tend to range from about 0.5 kW up to 3 kW. Going for a higher wattage can really make a difference because it helps break down particles more effectively, which is pretty much essential if you want your product to be uniform and consistent. Another thing to keep in mind is the operating pressure. Many high-pressure homogenizers run somewhere between 50 and 1500 bar, and that range is crucial for reducing particle sizes and improving emulsification — especially if you're working in industries like pharma or food processing, where precision really matters.

Don’t forget about the processing volume either. Small homogenizers are typically designed to handle anywhere from 10 mL up to 5 liters, so picking one that matches your production needs can really boost efficiency. Plus, the materials used and the design of the homogenizing chamber can play a role in how well it performs. For example, some models with microfluidic designs give you pretty fine control over particle size distribution—this is a game-changer in fields like nanotech, where CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD really shines. Making sure your homogenizer has these features will help you meet industry standards, improve product quality, and get better results overall.

In today’s super competitive manufacturing world, picking the right small homogenizer is a big deal. It’s key to boosting your product quality and making operations run smoother. Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD are really stepping up, offering advanced high-pressure homogenizers and microfluidizers that suit all kinds of industry needs. I was reading a recent market report, and it seems like the global market for homogenizers is expected to grow at about 5.4% annually. And, honestly, small homogenizers are becoming more popular because they’re so efficient—especially when it comes to emulsifying, dispersing, and breaking down particles into nanoscale sizes. crazy enough, huh?

When you're deciding between the different small homogenizers out there, it’s important to think about a few things. Things like how powerful the shear force is, how well it reduces particle size, and how easy it is to maintain. For example, some lab tests have shown that high-pressure homogenizers can bring particle sizes down to less than 100 nanometers, which really helps make products more stable and effective. Plus, it’s smart to compare the energy use and operating costs of different models—saving energy usually means saving money in the long run. CAS PETER’s focus on nanotech solutions really makes them stand out—they’re helping manufacturers optimize their processes with cutting-edge technology that makes a real difference.

| Model | Max Capacity (L) | Power (W) | Speed (RPM) | Material | Price ($) |

|---|---|---|---|---|---|

| Model A | 5 | 300 | 15000 | Stainless Steel | 1200 |

| Model B | 3 | 250 | 12000 | Aluminum | 900 |

| Model C | 10 | 500 | 20000 | Plastic | 1500 |

| Model D | 2 | 150 | 11000 | Glass | 600 |

| Model E | 7 | 400 | 17000 | Titanium | 1300 |

When you're choosing a small homogenizer for your manufacturing setup, it’s super important to think about both energy efficiency and how much it can produce. I recently came across a report from the International Journal of Food Engineering that mentioned energy use in homogenization can make up around 30% of your total production costs—crazy, right? That’s why picking a model with some modern energy-saving tech, like variable frequency drives or high-speed rotor-stator systems, can really make a difference. They help cut down power consumption while still keeping things running smoothly.

And then, there’s the production output. A study done by the American Institute of Chemical Engineers shows that top-notch homogenizers can boost your production rates by up to 50% compared to older or more basic models. That’s a big deal — not only do you get more efficiency, but you also get more consistent, higher-quality products. So, when you’re choosing a homogenizer, it’s smart to look for one that is both energy-efficient and capable of cranking out more product. This way, you’re not just saving some bucks on energy, but you’re also supporting your sustainability goals and improving your bottom line. Focusing on these factors really helps you pick the right equipment to meet the demands of today’s manufacturing world.

Small homogenizers have become pretty much essential across different industries these days. They’re great at making sure mixtures are uniform and products stay consistent — no surprises. Take the food and beverage world, for example; they really rely on small homogenization tech. When these machines finely blend emulsions and suspensions, it helps improve the texture and stability of things like sauces, dairy products, and smoothies. That way, companies can meet what consumers want: high-quality, tasty, and reliable products.

In pharma, small homogenizers are a total game-changer. They’re key for creating drug formulations that are both effective and uniform. These machines help mix active ingredients so that each dose has the right amount of medication — you definitely want that to be precise. And in cosmetics, small homogenizers come in handy for whipping up stable emulsions, which are super important for lotions, creams, and serums. When they do their job well, these products feel and look consistent, making customers happy and also checking off all the regulatory boxes.

Taking good care of your small homogenizer isn't just a good idea – it’s pretty much essential if you want it to last and work smoothly. First off, it helps a lot to set up a regular maintenance routine. That means giving it a thorough clean after each use. Why? Well, leftover product can clog things up and cause the machine to slow down or break down sooner. Using the right cleaning stuff and sticking to the manufacturer’s instructions will really help keep your equipment in tip-top shape. Also, don’t forget to check those seals and gaskets from time to time. If they’re cracked or worn out, you might end up with leaks or contamination, which nobody wants, especially when you're aiming for high-quality results.

Another thing — keep an eye on how the machine's running, specifically temperature and pressure settings. Staying on top of these means your product turns out consistent and helps catch any issues early before they turn into big problems. A bit of regular lubrication on moving parts can make a huge difference, preventing premature wear and tear and helping your homogenizer last longer. Honestly, spending just a little time on these simple maintenance steps can really boost how well your machine performs, and save you from costly repairs and downtime down the line. Trust me, it’s worth it!

This chart compares three different homogenizers based on key performance metrics: speed in RPM, output in liters per hour, power consumption in kilowatts, and noise level in decibels. Evaluating these metrics can help you choose the best small homogenizer for your manufacturing needs.

: Choosing the right homogenizer is crucial because it can significantly enhance product quality and consistency, which is essential in industries like food production and nanotechnology.

The right homogenization process can drastically influence particle size, which is essential for fluid dynamics and stability in various formulations.

Consider the specific requirements of your application, including the viscosity of the material and the desired particle size distribution, as well as scalability from lab to full production.

High-pressure homogenization ensures optimal performance characteristics in advanced materials like cellulose nanofibers or lipid-based nanoparticles by producing stable formulations with desirable properties.

Energy efficiency is important because energy consumption in homogenization can account for up to 30% of total production costs; choosing an energy-efficient homogenizer can lead to significant cost savings.

Advanced homogenizers can increase production rates by up to 50% compared to traditional models, leading to higher efficiency and improved product consistency and quality.

Technologies such as variable frequency drives or high-speed rotor-stator designs can minimize power usage while maintaining optimal performance.

Conducting regular particle size analyses helps monitor and maintain quality control throughout the production process, ensuring consistent product quality.

By focusing on energy efficiency and maximizing output, manufacturers can support their sustainability goals while also boosting their bottom line.

Look for a homogenizer that offers flexibility for different processing conditions and materials, allowing for versatility in applications.

When it comes to manufacturing, picking the right small homogenizer is a pretty big deal if you want consistent, high-quality products. Honestly, understanding how important homogenization is can really make a difference. So, when you're choosing a unit, you’ll want to pay close attention to key specs like pressure capacity, flow rates, and whether the materials are compatible—that kind of thing. Looking into the top small homogenizers on the market can give you a good sense of their energy efficiency and how much they can produce, which helps you make smarter choices that actually fit your needs.

And let’s be real, industries like food, beverages, and even pharma can totally benefit from the latest small homogenization tech. To get the most out of these machines and make them last longer, proper maintenance is a must. Companies like CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD really know their stuff when it comes to high-pressure homogenizers and microfluidizers. They offer customized nanotech solutions that are designed to meet all kinds of industry needs—and do it well.