When you’re navigating the world of food processing or pharmaceuticals, picking the right equipment can feel pretty overwhelming at times. Take Pressure Homogenizers, for example— they’re actually pretty crucial if you want to get that perfect product consistency and stability. I remember Dr. Emily Smith from Homogenization Technologies once mentioning, 'Choosing the right Pressure Homogenizer can really make or break your product quality.' And honestly, that couldn’t be more true.

A lot of businesses find themselves stuck here, unsure about which model to go with. There are so many options out there, each boasting different specs and performance features. It’s easy to get lost in the details or overlook the really important features while overcomplicating things. The goal should be to find a Pressure Homogenizer that actually helps boost your efficiency in production. But here's the thing— not every machine is a perfect fit for every application.

What’s really important is understanding your own specific needs. If you take the time to learn how these machines work, you’ll be in a much better position to make an informed decision. A good Pressure Homogenizer should help you break down particles more effectively and improve emulsions, sure— but it might not be the best solution for every product you’re working with. Bottom line? Being knowledgeable about what you need makes all the difference in the long run.

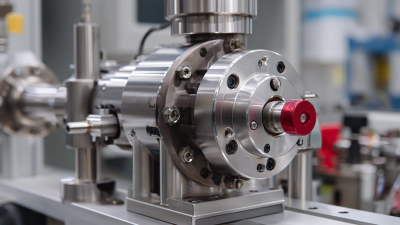

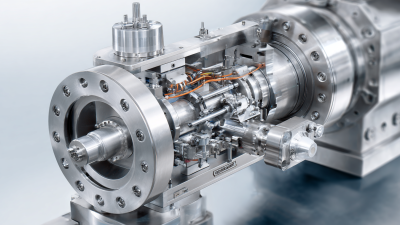

Pressure homogenization is a crucial process used in various industries. It involves forcing a fluid through a narrow space at high pressure. This creates intense shear forces and turbulence, effectively breaking down particles. The result is a more uniform mixture, essential for products like lotions and beverages.

In the world of food and pharmaceuticals, pressure homogenizers play a vital role. They ensure that products have consistent texture and viscosity. However, choosing the right equipment can be challenging. Not all homogenizers perform the same way. Factors like pressure range, flow rate, and energy consumption should be considered.

Understanding the technology is key. It can be overwhelming to navigate the options. While high pressure can yield better results, it may also compromise product integrity if not managed. Reflection on these trade-offs is necessary. Sometimes, the most expensive machine isn’t the best choice. Simple models may meet certain needs effectively. Balancing cost, efficiency, and quality is essential in making informed selections.

When selecting a pressure homogenizer, several key features are vital. The ability to adjust pressure levels is critical. This flexibility allows for different processing requirements. Consider the machine's capacity as well. A unit with a larger capacity may be beneficial for high-volume production. However, it can be overwhelming in smaller operations.

Another significant factor is the ease of maintenance. A complex system might look impressive, but it can lead to downtime. Operators should assess how user-friendly the machine is. A simple design can save time and effort, leading to better productivity. Additionally, energy efficiency is worth contemplating. Machines that consume less power not only lower costs but also have a smaller environmental impact.

Lastly, durability is essential. A robust machine can withstand long hours of operation. However, it's essential to scrutinize the materials used. A machine made from cheaper components might cost less upfront but can lead to future expenses. Weighing these factors carefully can ensure that the right choice is made, ultimately enhancing the production process.

In 2026, the landscape of pressure homogenization continues to evolve. Innovations focus on efficiency and quality. Industry reports show a surge in demand, with an estimated growth rate of 7.2% annually. This trend underscores the importance of selecting the right homogenizer.

The top brands in the sector emphasize energy-saving features. More than 40% of businesses prioritize these innovations to reduce costs. Compact designs now allow for easy integration into various production lines. However, some users report challenges with consistency in particle size distribution. This highlights a need for careful evaluation during selection.

Market analysis indicates that customer satisfaction hinges on reliability. Not every machine offers seamless operation. Reports suggest nearly one-quarter of users experience frequent maintenance issues. This dissatisfaction can lead to production delays. Choosing the right homogenizer requires balancing advanced technology and operational reliability.

| Model | Max Pressure (bar) | Flow Rate (L/h) | Power (kW) | Noise Level (dB) | Price ($) |

|---|---|---|---|---|---|

| Model A | 150 | 2000 | 18 | 75 | 8000 |

| Model B | 120 | 1800 | 15 | 70 | 7500 |

| Model C | 100 | 1600 | 12 | 68 | 6000 |

| Model D | 140 | 2200 | 20 | 80 | 9000 |

| Model E | 130 | 2500 | 22 | 82 | 9500 |

When evaluating the efficiency of a pressure homogenizer, specific performance metrics are crucial. First, examine the pressure range it operates within. Higher pressure typically results in finer emulsions or dispersions. Consider the flow rate as well. A higher flow rate means more product can be processed in less time. However, balancing pressure and flow is vital for optimal outcomes.

Another important aspect is the energy consumption of the homogenizer. Monitor how much energy it uses to achieve desired results. Sometimes, high efficiency can come at a higher energy cost. Don't overlook maintenance and durability. Homogenizers require regular upkeep to maintain their performance. Frequent breakdowns can lead to interruptions in your processes.

Finally, consider the size of the homogenizer. It should fit both your production scale and workspace. Sometimes, larger machines might not justify their space and complexity. Evaluate if a smaller, more efficient unit could meet your needs. This reflection is essential to ensure you invest wisely in equipment that serves your specific requirements.

Pressure homogenizers are crucial in various industries. They enable the production of stable emulsions and consistent particle sizes. In the food industry, for instance, the global market for homogenizers was valued at approximately $400 million in 2021. These machines help create creamier textures in dairy products. They also ensure better flavors by evenly distributing ingredients, which is essential for customer satisfaction.

The pharmaceutical sector relies heavily on pressure homogenizers. Reports indicate that the demand is increasing, with an expected growth rate of 5% annually. This equipment aids in formulating drug solutions with uniform particle sizes. Smaller particles can enhance bioavailability, leading to more effective medications. However, some manufacturers face challenges in optimizing their processes. Pressure adjustment and maintenance can affect product quality. Continuous improvement is essential.

Cosmetics is another field benefiting from these machines. Emulsions in lotions and creams require precise homogenization. Data shows that about 30% of consumers prefer products with labeled "homogenized." Companies must remain vigilant in quality control to meet this growing preference. Inconsistencies can lead to product recalls and loss of reputation. Addressing these pitfalls is crucial for success.

When choosing a pressure homogenizer, user feedback is invaluable. Many individuals share their unique experiences with different models. Some users rave about efficiency and consistency. Others, however, highlight design flaws that cause frustration during operation. It's essential to consider both sides before making a decision.

A common theme among user reviews is maintenance challenges. Some found it difficult to clean the machine after use. Others reported issues with parts wearing out too quickly. These concerns hint at the need for better durability. Many users also mention the importance of customer support. Quick responses from manufacturers can make a difference during troubleshooting.

The design and functionality can vary widely. While some machines excel in processing speed, they might produce inconsistent results. Others may be robust but harder to handle. Users often express their personal preferences, which adds depth to the feedback. Ultimately, real experiences provide crucial insight for those in search of the perfect pressure homogenizer tailored to their needs.

Pressure homogenization technology is evolving rapidly. This innovation is essential in various industries. It improves product quality and consistency. The future is leaning towards increased efficiency and sustainability. Machines will likely integrate advanced features that optimize energy use. This shift could significantly reduce operational costs.

New materials are also emerging. These materials may enhance durability and performance. They can withstand higher pressures and temperatures. However, there are challenges ahead. Not all facilities can easily transition to newer technologies. There may be training needs as well. Employees will require updated skills to operate advanced systems.

The emphasis on sustainability will drive future trends. Companies aim to reduce their environmental footprint. There may be more focus on waste reduction and recycling. However, the industry must reflect on its practices. Some current processes are not environmentally friendly. This is a critical area for improvement as technology advances. Balancing innovation with responsibility is the key.

: The product aims to enhance daily activities and improve overall efficiency. It simplifies tasks for better user experience.

Follow the user guide step by step. Ensure you understand each feature. Practice regularly to improve your skills.

Yes, it may not perform well under extreme conditions. User errors can lead to unexpected results. Always check settings.

Restart the device first. If issues persist, consult troubleshooting tips. Reach out to support if needed.

It is designed for a wide audience but may not suit everyone. Beginners might find it challenging without guidance.

There is typically a warranty period available. Ensure to read the policy carefully before making a purchase.

In the quest for the best pressure homogenizer in 2026, it is essential to understand the fundamentals of pressure homogenization. This technology plays a crucial role in various industries, from pharmaceuticals to food production, by improving product consistency and stability. When selecting a pressure homogenizer, several key features should be considered, including the design, capacity, and ease of maintenance, ensuring it meets specific operational needs.

Evaluating the efficiency of a pressure homogenizer can be done through performance metrics like particle size distribution and homogenization degree. User feedback from current models highlights practical insights into real-world applications, helping potential buyers make informed decisions. As we look to the future, innovations in pressure homogenization technology promise to enhance efficiency and broaden its applications, ensuring that industries continue to benefit from these powerful machines.