In the world of manufacturing, staying competitive really depends on how efficient and effective your production processes are. Lately, using advanced tech like the Valve Homogenizer has become a total game-changer across various industries — think food, pharma, cosmetics, you name it. I remember reading a report by the International Society for Pharmaceutical Engineering (ISPE) that says the global market for homogenization equipment could hit over $1.5 billion by 2025 — shows how much companies are counting on these tools to make their products more uniform and top-notch.

Experts like Dr. Emily Carter, who's pretty renowned in food tech circles, often highlight how important homogenization is. She mentioned that a Valve Homogenizer doesn’t just make products more stable — it also improves how they taste and feel, which is a big deal in delivering quality stuff to consumers. Thanks to its precise control and the shear forces it creates, these homogenizers help manufacturers get that perfect, uniform texture in their products — which, in the end, really amps up customer satisfaction.

As industries keep evolving, it’s super important to understand how adding a Valve Homogenizer into your production line can be a total win. It can boost your yield, help you meet all those tough regulatory standards, and bring a bunch of other benefits. So, in this article, I’m gonna go over the top ten perks of using a Valve Homogenizer and explain how it can really shake up your production process and help your business thrive.

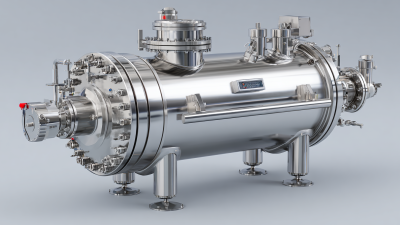

Valve homogenizers are essential tools in various production processes, particularly in the food, pharmaceutical, and cosmetic industries. These devices function by forcing a product through a narrow valve at high pressure, which causes the materials to experience intense shear forces. This results in a more uniform particle size and a stable emulsion, crucial for products that rely on consistency and quality. By using a valve homogenizer, manufacturers can achieve the desired texture and viscosity, allowing for better control over the final product characteristics.

The operation of a valve homogenizer is based on fluid dynamics principles, combining mechanical and hydraulic forces to break down solids in a liquid medium. During the homogenization process, materials are subjected to turbulence and cavitation, which further enhance the breakdown of particles. This technology not only improves the stability and shelf life of products but also optimizes the production efficiency by reducing the need for additional processing steps. With the ability to fine-tune the operational parameters, such as pressure and flow rate, valve homogenizers offer flexibility for manufacturers to adapt to different formulations and meet varying production demands.

Valve homogenization plays a pivotal role in enhancing product consistency across a range of production processes. By utilizing high-pressure valves, this technology effectively reduces particle sizes and eliminates inconsistencies in the formulated products. With a focus on achieving a uniform texture and composition, valve homogenizers ensure that every batch of product meets the stringent quality standards required in industry. This process not only improves the visual appeal of the product but also impacts its flavor, stability, and overall performance in various applications.

Moreover, the enhanced consistency achieved through valve homogenization contributes to increased consumer satisfaction and product reliability. When customers can expect the same high quality with each use, brand loyalty is strengthened. Additionally, the reduced variability in product characteristics facilitates easier scaling of production, allowing businesses to meet market demands more effectively. As industries recognize the importance of product consistency, valve homogenization stands out as an essential technology for maintaining competitive advantage in a rapidly evolving marketplace.

Homogenization is a crucial process in food and beverage production, significantly enhancing the shelf life of products.

By breaking down fat globules into smaller, more uniform sizes, a valve homogenizer ensures a stable emulsion. This reduction in particle size creates a more homogenous mixture, preventing separation and sedimentation over time.

As a result, products maintain their desirable texture and consistency, making them more appealing to consumers while reducing the chances of spoilage.

Additionally, homogenization impacts the overall safety and quality of food products. By improving the stability of emulsions and suspensions, it minimizes the risk of microbial growth, often associated with separation.

Products that undergo effective homogenization can exhibit a longer shelf life without the need for excessive preservatives. This not only meets consumer demand for cleaner ingredient lists but also reduces waste in production and retail, contributing to a more sustainable food system.

Ultimately, implementing homogenization techniques is a valuable strategy for manufacturers looking to enhance their product longevity and reliability.

The use of valve homogenizers in production processes offers significant cost-effectiveness, making them an essential investment for manufacturers. These machines facilitate the blending and emulsification of products, ensuring a uniform consistency that can enhance product quality. The efficiency of valve homogenizers not only reduces waste but also minimizes the need for additional processing equipment, ultimately lowering overall production costs. By optimizing the use of raw materials, companies can improve their profit margins while maintaining high standards of quality.

When implementing valve homogenizers, manufacturers should consider a few practical tips to maximize cost savings. First, ensure regular maintenance of the equipment to avoid downtime and costly repairs. A well-maintained homogenizer operates more efficiently, reducing energy consumption and lowering operational costs. Second, train staff to operate the machines effectively; skilled operators can minimize the time spent on processing and enhance output. Lastly, evaluate the specific production needs to select the right settings and parameters, which can lead to further savings by optimizing throughput and minimizing ingredient waste.

Moreover, the scalability of valve homogenizers allows businesses to adjust their production levels without significant additional investments. This flexibility enables companies to respond to market demand dynamically, improving cash flow management. Leveraging valve homogenizers can ultimately transform production processes, driving not only quality but also significant savings that enhance the bottom line.

Valve homogenizers play a critical role across various industries by enhancing the efficiency and quality of production processes. In the food and beverage sector, these machines are used to achieve uniform particle size in emulsions, ensuring consistent texture and flavor. For instance, in dairy processing, valve homogenizers help in producing smooth milk and cream, improving mouthfeel and stability. Likewise, in the manufacturing of sauces and dressings, they facilitate the blending of oil and water phases, preventing separation and prolonging shelf life.

In the pharmaceutical industry, valve homogenizers are essential for creating stable suspensions and emulsions, ensuring that active ingredients are evenly distributed throughout products. This uniformity is crucial for dosage accuracy and patient safety. Furthermore, in the cosmetics industry, these machines are employed to formulate lotions and creams, achieving a consistent and appealing texture that enhances product performance. Overall, the versatility of valve homogenizers allows them to meet the specific requirements of different industries, contributing significantly to product quality and operational efficiency.

Using valve homogenizers in production processes offers significant environmental benefits that contribute to sustainability and reduced ecological impact. One of the primary advantages is the efficient use of resources, as valve homogenizers minimize waste by ensuring uniformity in product consistency and reducing the need for excessive raw materials. This efficiency not only cuts down on manufacturing costs but also lowers the amount of waste sent to landfills, supporting a more sustainable production cycle.

Furthermore, valve homogenizers enhance energy efficiency during the production process. By achieving optimal particle size and consistency in a single pass, they eliminate the need for multiple processing steps that consume additional energy. This reduction in energy expenditure not only leads to cost savings for manufacturers but also decreases greenhouse gas emissions associated with energy production. In an era where companies are increasingly urged to adopt greener practices, utilizing valve homogenizers can significantly bolster a company's commitment to environmental stewardship and responsible manufacturing.

Valve homogenizers are renowned for their ease of maintenance and operation, making them a popular choice in various production processes. Their design typically incorporates fewer moving parts compared to traditional homogenizers, which simplifies both upkeep and troubleshooting. This reduction in complexity means that operators can quickly identify and address maintenance needs without extensive technical training. Regular maintenance tasks, such as cleaning and part replacement, can often be completed in a streamlined manner, enhancing overall productivity.

Another advantage is the user-friendly operation of valve homogenizers. Many models feature intuitive controls that allow for precise adjustments to processing parameters. This control not only ensures consistent product quality but also minimizes the risk of operator error. Training staff to operate these systems is generally less time-consuming, facilitating quicker onboarding and less disruption in production timelines. With straightforward operational protocols, businesses can achieve significant operational efficiency while maintaining high standards of product quality.

: Valve homogenization is a technology that enhances product consistency in production by utilizing high-pressure valves to reduce particle sizes and eliminate inconsistencies, ensuring uniform texture and composition across batches.

By ensuring a uniform texture and composition, valve homogenization improves the visual appeal, flavor, stability, and overall performance of products, which contributes to higher consumer satisfaction.

Homogenization enhances shelf life by creating stable emulsions that prevent separation and sedimentation, maintaining desirable textures and reducing spoilage risks associated with microbial growth.

By improving the stability of emulsions and suspensions, homogenization minimizes the risk of microbial growth, leading to safer food products and reducing the need for excessive preservatives.

The reduced variability in product characteristics achieved through valve homogenization makes it easier for businesses to scale production and meet market demands effectively.

Valve homogenizers are easier to maintain due to their design, which has fewer moving parts, allowing for quick troubleshooting and streamlined upkeep, thus enhancing overall productivity.

Valve homogenizers often feature intuitive controls for precise adjustments, making them user-friendly and facilitating quicker staff training and onboarding.

When consumers can expect the same high quality from each use, it strengthens brand loyalty and improves their overall satisfaction with the product.

By prolonging shelf life and reducing the need for preservatives, homogenization techniques contribute to lower waste in production and retail, supporting a more sustainable food system.

Industries that implement valve homogenization can maintain a competitive advantage by ensuring product consistency, which is increasingly recognized as vital in a rapidly evolving marketplace.

Valve homogenizers are essential tools in modern production processes, known for their ability to enhance product consistency and improve the shelf life of various products. By utilizing high pressure to finely blend and homogenize ingredients, valve homogenizers ensure uniformity in texture and taste, which is critical for customer satisfaction. Additionally, these systems are recognized for their cost-effectiveness, as they optimize resource use while minimizing waste.

Furthermore, valve homogenizers have applications across multiple industries, from food and beverage to pharmaceuticals, demonstrating their versatility. They also contribute positively to environmental sustainability by reducing energy consumption during processing. Lastly, the ease of maintenance and operation of valve homogenizers makes them an attractive addition to any production line, allowing for efficient and continuous production with minimal downtime.