In the pharma world, making sure your products are top-notch is a big deal. One of the key tools that helps get at that high standard is the Pharmaceutical Homogenizer Machine. These machines are pretty amazing—they really help make formulations more uniform and stable. That’s super important because it keeps the drugs effective. Basically, they break down particles and spread everything out evenly, which boosts both the physical and chemical qualities of different formulations.

Plus, using a Pharmaceutical Homogenizer Machine in quality checks really helps with meeting strict regulations and makes sure that products are consistent and reliable. As folks keep demanding better-quality meds, having this kind of technology becomes more and more essential. Jumping on board with these machines allows manufacturers to work more smoothly and confidently that every product is safe and effective. All in all, investing in pharmaceutical homogenization isn’t just about keeping up—it’s about shaping the future of pharma manufacturing. It opens doors to new, innovative solutions that benefit both companies and the people using their products.

Pharmaceutical homogenizer machines are essential in the pharmaceutical industry, especially for quality control and product consistency. These machines ensure that active ingredients are uniformly distributed within formulations, which is critical for achieving the desired therapeutic effects. According to a report by the International Pharmaceutical Excipients Council, up to 80% of drug formulations require homogenization to ensure optimum performance and stability. This highlights the significance of these machines in maintaining product quality and compliance with regulatory standards.

Tips: When selecting a homogenizer, consider factors such as the viscosity of your formulation and the required particle size reduction. Ensuring that the equipment is suitable for your specific needs can significantly enhance the quality control process.

Moreover, pharmaceutical homogenizer machines offer advantages such as reducing the processing time and improving the reproducibility of results. These machines can efficiently produce emulsions, suspensions, and solutions with minimal variations, which is critical in determining the safety and efficacy of pharmaceutical products. Research indicates that homogenized products can exhibit up to 30% improved bioavailability compared to their non-homogenized counterparts, making these machines a vital investment in quality assurance.

Tips: Regular maintenance and calibration of homogenizers are crucial for consistent performance. Establishing a routine will help identify potential issues early and ensure reliable operation.

| Benefit | Description | Impact on Quality Control |

|---|---|---|

| Uniform Particle Size | Ensures all particles are of a consistent size, which improves product stability. | Enhances bioavailability and efficacy of drug products. |

| Increased Stability | Reduces sedimentation and aggregation, leading to stable formulations. | Prolongs shelf life and effectiveness of pharmaceutical products. |

| Improved Efficiency | Speeds up the homogenization process compared to traditional methods. | Reduces production time and costs. |

| Enhanced Quality Assurance | Facilitates consistent and reproducible results for quality testing. | Meets regulatory standards and ensures product safety. |

| Versatility | Can be used for a variety of formulations, including emulsions and suspensions. | Allows for comprehensive testing across different product types. |

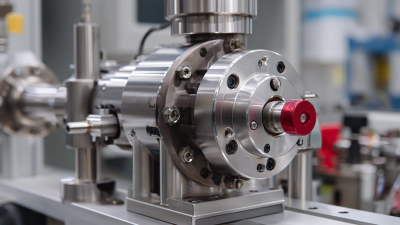

In the pharmaceutical industry, homogenizer machines play an essential role in ensuring product consistency, efficacy, and safety. These machines help in the uniform distribution of active pharmaceutical ingredients (APIs) within the excipient matrix, which is critical for achieving precise dosage forms. According to a report by Grand View Research, the global homogenizers market is projected to reach USD 1.18 billion by 2025, indicating the growing reliance on these machines for quality control in pharmaceutical manufacturing.

One key function of homogenizer machines is to reduce the particle size of drug formulations, which enhances bioavailability. This is particularly important for poorly soluble compounds, as smaller particle sizes lead to increased surface area and improved dissolution rates. A study published in the International Journal of Pharmaceutics highlights that using high-pressure homogenization can result in a remarkable decrease in particle size, often down to the nanometer range. This not only aids in the efficiency of the drug but also ensures that the final product meets stringent regulatory standards.

**Tips:** When selecting a homogenizer machine, consider the scale of production and specific formulation needs. It is essential to evaluate the machine's capabilities, from basic homogenization to advanced features like temperature control and pressure monitoring. Regular maintenance and calibration of the homogenizer are also crucial for maintaining consistent quality output and adherence to Good Manufacturing Practices (GMP) in pharmaceutical production.

Uniform particle size is crucial in drug formulation as it directly affects the drug’s efficacy, stability, and overall patient safety. Pharmaceutical homogenizer machines play an essential role in achieving this uniformity, leading to consistent dosing and reliable therapeutic outcomes. When the particle size is uniform, it enhances the dissolution rate of the active pharmaceutical ingredients, allowing for quicker absorption in the body. This is particularly important for medications that require rapid onset of action, ensuring patients receive the intended therapeutic effects promptly.

Moreover, consistent particle size distribution contributes to improved stability of the final product. A uniform formulation reduces the likelihood of phase separation and sedimentation, which can compromise the drug's effectiveness and shelf life. Furthermore, enhanced uniformity can facilitate better processing during manufacturing, minimizing the risk of defects and ensuring compliance with quality control standards. In essence, utilizing pharmaceutical homogenizer machines not only streamlines production but also fortifies the quality and reliability of drug formulations, ultimately benefiting both manufacturers and consumers.

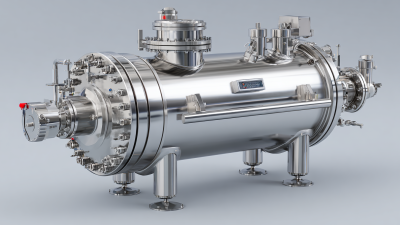

Homogenization plays a crucial role in enhancing the stability and efficacy of pharmaceutical products. By processing drug formulations through homogenizer machines, manufacturers are able to achieve a uniform particle size distribution. This uniformity not only improves the solubility of active pharmaceutical ingredients but also enhances their bioavailability. When drug particles are reduced to a smaller, more consistent size, they dissolve more readily in bodily fluids, leading to more effective absorption and therapeutic action.

Moreover, homogenization can significantly impact the shelf life of pharmaceutical products. By breaking down larger particles and creating a stable emulsion or suspension, the potential for sedimentation or phase separation is minimized. This stability is particularly important for suspensions and emulsions, where inconsistent particle sizes can lead to variable dosing and reduced effectiveness. Ensuring a stable formulation through homogenization helps maintain the integrity of the drug over time, providing reliable therapeutic outcomes.

Tips: When using homogenizer machines, it's essential to monitor the temperature and pressure settings to prevent degradation of heat-sensitive compounds. Regular maintenance and calibration of equipment can also help maintain the consistency of particle sizes, ensuring optimal drug performance. Always conduct stability tests on products before full-scale production to assess their efficacy and storage requirements.

Pharmaceutical homogenizer machines play a pivotal role in enhancing quality assurance within the pharmaceutical manufacturing process. By ensuring uniformity and consistency in product formulations, these machines help minimize variations that could adversely affect the efficacy and safety of medications. The ability to achieve a homogenous mixture is essential, as even slight discrepancies in particle size or distribution can lead to significant differences in how a drug behaves in the body. This consistency not only meets regulatory requirements but also instills confidence in both healthcare providers and patients regarding the quality of the products they use.

Moreover, employing advanced homogenization technology streamlines quality control processes, enabling manufacturers to conduct real-time assessments of product performance. By integrating homogenizers into the production line, companies can continuously monitor and adjust parameters to ensure that each batch maintains the required standards. This proactive approach to quality assurance not only reduces the likelihood of recalls or batch failures but also promotes a culture of continuous improvement. Ultimately, the implementation of pharmaceutical homogenizer machines is crucial for achieving high-quality outcomes that meet the stringent demands of the industry while safeguarding public health.

In the pharmaceutical industry, adherence to regulatory compliance and standards is crucial for maintaining high-quality products and ensuring patient safety. Homogenizer machines play a vital role in quality control by providing uniformity in the formulation of pharmaceutical products. Regulatory bodies such as the FDA and EMA stipulate guidelines that require pharmaceutical manufacturers to implement consistent processing methods, making the use of homogenizers essential for meeting these standards. By ensuring that mixtures are consistently emulsified or dispersed, homogenizers help fulfill the requirements outlined in Good Manufacturing Practices (GMP), which are critical for quality assurance and product integrity.

Tips for ensuring compliance with homogenizer use include regular calibration and maintenance of the machines to ensure they operate within specified parameters. It is also important to document all homogenization processes meticulously, including batch records and any deviations from standard operating procedures. This documentation is essential not only for internal audits but also for regulatory inspections, demonstrating a commitment to quality and compliance.

Additionally, training personnel on the proper use and operating principles of homogenizers is imperative. Employees should be well-versed in best practices, including the importance of proper cleaning and sanitization protocols, to avoid contamination and ensure a sterile environment. These steps help reinforce a culture of quality control, ultimately supporting compliance efforts and enhancing product safety and efficacy.

The landscape of pharmaceutical homogenization is rapidly evolving with technological advancements that promise to enhance efficiency and product quality. Future trends in pharmaceutical homogenization technologies are gravitating towards automation and precision. With the integration of smart systems and IoT connectivity, manufacturers can now monitor homogenization processes in real-time, leading to consistent product quality and reduced waste. This innovation allows for better data analytics and predictive maintenance, ensuring that equipment operates at peak efficiency.

Tips for adopting these new technologies include investing in training for staff to effectively utilize advanced systems and to keep abreast of emerging trends in the field. Additionally, collaborating with technology providers can offer insights into the best practices for implementation, allowing businesses to harness these advantages fully.

Another significant trend is the shift towards more sustainable and eco-friendly homogenization practices. Manufacturers are now focusing on reducing energy consumption and waste generation, which not only complies with stringent regulations but also enhances their market reputation. Utilizing advanced homogenization techniques that require less energy and produce smaller, more uniform particle sizes can contribute to more effective drug formulations and ultimately better patient outcomes.

: Homogenizer machines are vital for achieving uniform distribution of active pharmaceutical ingredients (APIs) within excipient matrices, ensuring product consistency, efficacy, and safety.

They reduce the particle size of drug formulations, which increases the surface area and improves dissolution rates, particularly for poorly soluble compounds.

Smaller particle sizes lead to better drug efficiency and ensure that the final product complies with stringent regulatory standards.

They should evaluate the scale of production, specific formulation needs, and the machine's capabilities, including advanced features like temperature control and pressure monitoring.

Homogenizers ensure uniformity and consistency in product formulations, minimizing variations that can affect drug efficacy and safety.

They enable real-time assessments and adjustments, allowing manufacturers to continuously monitor product quality throughout production.

Regular maintenance and calibration are crucial for maintaining consistent quality output and adherence to Good Manufacturing Practices (GMP).

By ensuring high-quality pharmaceutical products that meet industry standards, homogenizers help safeguard public health and maintain trust among healthcare providers and patients.

Pharmaceutical Homogenizer Machines play a crucial role in quality control within the pharmaceutical industry. By achieving uniform particle size, these machines ensure optimal drug formulation, enhancing the stability and efficacy of pharmaceutical products. The key functions of these homogenizers not only improve product performance but also bolster quality assurance practices, leading to consistent outcomes that meet regulatory compliance and standards.

As the pharmaceutical sector continues to evolve, the use of Pharmaceutical Homogenizer Machines is expected to advance with emerging technologies that further enhance their efficiency. These innovations will likely focus on delivering superior results in drug development processes, ultimately ensuring higher quality products for consumers while adhering to stringent regulatory requirements.