In today’s fast-changing world of pharmaceuticals, getting production just right—both in terms of efficiency and quality—is more important than ever. That’s where the Pharmaceutical Homogenizer Machine really steps in; it’s essential for keeping formulations consistent every time. I came across a report from the Pharmaceutical Manufacturing Association that said nearly 70% of manufacturers have seen better product stability thanks to these machines. That really highlights how critical homogenization is in making sure everything turns out as it should.

Dr. Emily Chen, who’s a top expert in pharma tech, points out, "The right homogenizer can seriously boost bioavailability," which is a fancy way of saying it makes drugs work better in our bodies. This shows just how vital these machines are for creating effective medications. They help ensure that particles are uniformly broken down and well-dispersed, leading to better treatment outcomes. With the industry under increasing pressure to meet tough quality standards, investing in advanced homogenization techniques is more important than ever.

That said, it’s worth considering some of the hurdles that come with adopting new tech like the Pharmaceutical Homogenizer Machine. The initial costs can be pretty steep, and training staff on how to use these machines properly isn’t always given enough attention. Finding that sweet spot between embracing innovation and making sure it’s practical and manageable is key to actually enjoying all the benefits these machines can offer.

Homogenizers play a crucial role in the pharmaceutical industry. They ensure uniformity in drug formulations. This consistency is vital for efficacy and safety. It reduces batch-to-batch variation, which can lead to unpredictable results in treatments. A well-homogenized product performs as intended, enhancing patient outcomes.

One key benefit lies in the formation of stable emulsions. Stability prevents ingredients from separating. This is crucial for liquid medications. Enhanced solubility leads to better absorption in the body. However, achieving the perfect balance can be a challenge. Over-homogenization might degrade sensitive compounds. Careful monitoring during production is essential.

Another advantage is the production of smaller particle sizes. Smaller particles improve the bioavailability of drugs. This means that lower doses can be effective. However, there is a risk of inconsistent size distribution if processes aren’t optimized. Companies need to invest in quality control measures. Proper training of staff operating homogenizers is equally important. Ultimately, while homogenizers offer significant benefits, constant evaluation and adjustment are required for optimal results.

Pharmaceutical homogenizer machines play a crucial role in drug formulation. They ensure consistent and effective particle size reduction. Improved particle size directly correlates with drug bioavailability. Studies show that smaller particle sizes lead to increased surface area. This can enhance the dissolution rate of active pharmaceutical ingredients (APIs). For instance, a report by the International Journal of Pharmaceutics indicates that reducing particle size to below 5 micrometers can improve bioavailability by up to 45%.

It is essential to recognize that not all homogenization processes yield the same results. Variability in machine performance may occur. Factors such as temperature, pressure, and flow rate all play a role in achieving optimal results. A well-established protocol is vital to minimize inconsistencies. For example, if a machine operates outside its specified parameters, it may produce larger particles, ultimately diminishing drug effectiveness. This highlights the importance of thorough testing and validation in production settings.

Moreover, the impact of particle size extends beyond bioavailability. It also influences stability and therapeutic efficacy. Larger particles can lead to aggregation, resulting in unpredictable drug release profiles. Reports suggest that improper homogenization could risk therapeutic outcomes. Researchers must continuously evaluate and refine homogenization techniques for better results. The ongoing quest for precision in pharmaceutical formulations remains a significant challenge in the industry.

Pharmaceutical homogenizer machines play a crucial role in enhancing production efficiency within the pharmaceutical industry. By creating uniform mixtures, these machines streamline various processes. Reports indicate that efficient homogenization can reduce production time by up to 30%. This time savings is significant, particularly in processes requiring precise formulation and consistency.

Moreover, the usage of homogenizers leads to a decrease in product wastage. Traditional mixing methods often lead to inconsistencies, causing batches to be rejected. This not only wastes raw materials but also consumes additional time and resources. Industry studies suggest that implementing homogenization can reduce product rejection rates by up to 20%. While the initial investment in homogenizer technology may seem high, the long-term savings in time and materials are compelling.

Despite these benefits, challenges remain. Training staff to effectively operate homogenization machines is essential but often overlooked. Additionally, there have been instances where poor maintenance led to inconsistent results, highlighting the need for regular checks. This inconsistency can undermine the benefits achieved, suggesting that continuous improvement is necessary for optimal efficiency.

The use of pharmaceutical homogenizer machines can significantly reduce production costs. These machines create uniform mixtures, ensuring consistent quality in products. By minimizing variations, companies can decrease the amount of raw materials needed. This leads to less waste, which is crucial for budget management.

Homogenizers can also enhance product yield. When the mixing process is efficient, manufacturers obtain more from each batch. This directly impacts profitability. However, initial investment in such equipment can be high. Companies must weigh the costs against potential long-term savings.

In some cases, not all formulations behave well during homogenization. There might be unexpected challenges that require adjustments. This adds complexity to the process. Yet, embracing this technology could streamline operations and boost overall efficiency. The balance between cost, quality, and equipment investment needs careful evaluation.

Pharmaceutical homogenizer machines play a crucial role in enhancing the stability and shelf life of pharmaceutical products. These machines ensure uniform dispersion of active ingredients. This uniformity helps prevent settling or separation, which leads to more effective medications.

In practical terms, a stable formulation can maintain its potency over time. The right homogenization technique minimizes particle size, improving solubility. When ingredients are evenly distributed, patients receive the intended dosage with each administration. This process can also extend the shelf life, reducing the likelihood of degradation.

Tip: Monitor temperature during homogenization. Excessive heat can impact the integrity of sensitive compounds.

A critical aspect to consider is the equipment’s maintenance. Regular cleaning and calibration are essential for consistent results. Neglect can introduce contamination, affecting product stability. Suppliers should educate their clients about these routines to ensure optimal performance.

Tip: Keep a maintenance log. Document every service and any irregularities in operation. Patterns may reveal underlying issues needing attention.

Attention to detail in the homogenization process leads to higher-quality products. This commitment to quality can drive success in the competitive pharmaceutical market. Each step, from formulation to packaging, matters.

| Benefit | Description | Impact on Stability |

|---|---|---|

| Uniform Particle Size | Produces consistent particle size in formulations, enhancing product performance. | Improves dispersion stability and reduces sedimentation. |

| Enhanced Bioavailability | Increases the rate at which active ingredients are absorbed. | Leads to improved therapeutic effectiveness. |

| Reduced Viscosity | Facilitates easier handling and processing of viscous formulations. | Ensures better stability during storage. |

| Improved Shelf Life | Enhances the longevity of pharmaceutical products by reducing degradation. | Helps maintain potency over time. |

| Cost Efficiency | Reduces the need for additional stabilizers or preservatives. | Contributes to overall cost reduction in production. |

| Versatility | Can be used for a wide range of formulations including creams, emulsions, and suspensions. | Ensures consistent quality across different products. |

| Control over Microbial Growth | Reduces microbial load through high shear force. | Enhances safety and product stability. |

| Regulatory Compliance | Meets stringent industry standards for pharmaceutical manufacturing. | Ensures product stability in compliance with regulations. |

| User-Friendly Operation | Simplifies the homogenization process with automated features. | Promotes consistent results and reduces operator error. |

| Reduction of Side Effects | Enhances the stability and efficacy of active pharmaceuticals, minimizing adverse effects. | Improves patient compliance and satisfaction. |

Pharmaceutical homogenizer machines play a critical role in ensuring product quality. They contribute significantly to compliance with strict regulatory standards. Advanced homogenization techniques allow for consistent particle size reduction, enhancing the stability and efficacy of formulations. Companies must adhere closely to these standards, making compliance a top priority.

Using advanced homogenization techniques, manufacturers can achieve homogeneity in their products. This process not only helps in meeting regulatory guidelines but also ensures that active ingredients are evenly distributed. The consistency produced reduces variability, a key requirement in pharmaceutical production. However, relying solely on technology can sometimes lead to oversights.

Manufacturers must periodically reflect on their homogenization processes. Regular audits and quality checks are essential to maintain compliance. Implementing more comprehensive training for personnel can help mitigate mistakes. Despite the advantages of homogenization, the human element remains crucial for perfecting production standards. Balancing technology and human oversight leads to better outcomes in pharmaceutical manufacturing.

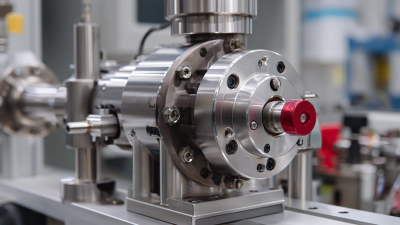

Pharmaceutical homogenizers play a crucial role in the production of various drug formulations. These machines ensure that active ingredients are evenly distributed throughout the mixture. This is vital for maintaining product consistency and efficacy. Homogenizers are used in creating emulsions, suspensions, and liposomal formulations. Their versatility makes them an essential tool in every pharmaceutical lab.

The adaptability of homogenizers extends to many applications. They are effective in developing creams, ointments, and gel formulations. Each formulation requires specific parameters, like temperature and pressure, to achieve the desired particle size and distribution. Sometimes, achieving the right texture can be challenging. Operators may need to experiment with settings to meet product specifications. The process is not always straightforward and can lead to inconsistencies if not monitored closely.

Homogenizers also serve in producing vaccines and injectable drugs. In these cases, uniform particle size is critical. Inadequate homogenization may cause variations in dose delivery. Careful attention is essential to ensure patients receive the intended dosage. This underscores the complexity and importance of these machines in the pharmaceutical industry. Their versatility is evident, but it comes with the responsibility of precise calibration and operation.

: The product aims to improve daily convenience for users. It simplifies tasks and saves time.

Follow the instructions provided in the manual. Ensure you understand settings before starting.

Yes, but check the weather. Excessive rain or humidity may damage it.

Typically, a warranty is offered. Review the terms to understand your coverage.

Avoid situations that could lead to accidents. Always supervise use around children.

First, check the power source. If issues persist, consult the troubleshooting guide.

Repairs are possible, but might be costly. Assess whether replacement is a better option.

Regular maintenance is crucial. Clean it monthly for optimal performance and longevity.

Yes, think creatively! There may be unconventional ways to use it effectively.

Check the return policy. Conditions may apply, and time frames vary.

Pharmaceutical homogenizer machines play a crucial role in enhancing the drug formulation process by ensuring consistency and improving particle size reduction, ultimately leading to better drug bioavailability. By utilizing these advanced machines, pharmaceutical manufacturers can achieve increased production efficiency and significant time savings while also reducing overall production costs.

Additionally, the stability and shelf life of pharmaceutical products are greatly enhanced through effective homogenization techniques. Compliance with regulatory standards is further assured as these machines employ state-of-the-art technologies that are versatile and applicable across various pharmaceutical applications. Overall, the integration of pharmaceutical homogenizer machines yields numerous benefits that contribute to the advancement of drug development and manufacturing.