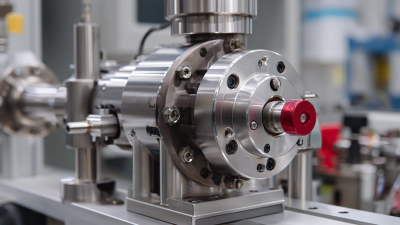

In today’s fast-moving world of science, getting great results in the lab is more important than ever for researchers and businesses alike. At CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD, we’re all about offering the latest solutions for high-pressure and microfluidic homogenization—focusing on innovative tech that really makes a difference. One star tool we’re excited about is the Nano Debee Homogenizer. It’s known for its incredible efficiency when it comes to making nanoscale emulsions and dispersions.

In this post, I’ll share some tips and best practices to help you get the most out of your Nano Debee Homogenizer in the lab. Trust me, by adopting these strategies, you’ll maximize its potential and can really take your research or production to the next level. Let’s dive in and see how you can turn this powerful device into a game-changer for your projects!

The Nano Debee Homogenizer is really changing the game when it comes to sample prep in labs across a bunch of different fields. Compared to the old-school homogenizing methods, it offers some pretty impressive benefits. What’s cool is that it uses cutting-edge tech to generate really high shear forces, which means it’s great at breaking open cells and emulsifying samples effectively. I read in the International Journal of Biotechnology that systems like Nano Debee can get particle sizes down to around 10 nanometers — that’s huge for making samples more bioavailable, especially in pharma and nutrition stuff.

On top of that, the Nano Debee is super efficient. According to a study in the Journal of Food Science, labs using high-pressure homogenization can cut their processing times by half — yeah, up to 50%! And it doesn’t just save time; it actually makes the results more consistent and reproducible. That’s a big plus because it helps researchers get more precise, reliable results without the usual variability. As more labs look for high-quality samples, having a tool like the Nano Debee is becoming pretty much essential if you’re aiming for top-notch results and efficiency.

| Feature | Description | Benefit |

|---|---|---|

| High Shear Rate | Generates intense mechanical shear forces. | Improves homogenization efficiency and particle size reduction. |

| Temperature Control | Ensures consistent temperature during processing. | Prevents heat-sensitive sample degradation. |

| Versatile Applications | Suitable for a wide range of samples including cells, tissues, and emulsions. | Facilitates diverse research projects and applications. |

| Automated Operation | Features programmable settings for reproducibility. | Enhances workflow efficiency and consistency. |

| Compact Design | Space-saving structure ideal for laboratory environments. | Maximizes laboratory space utilization. |

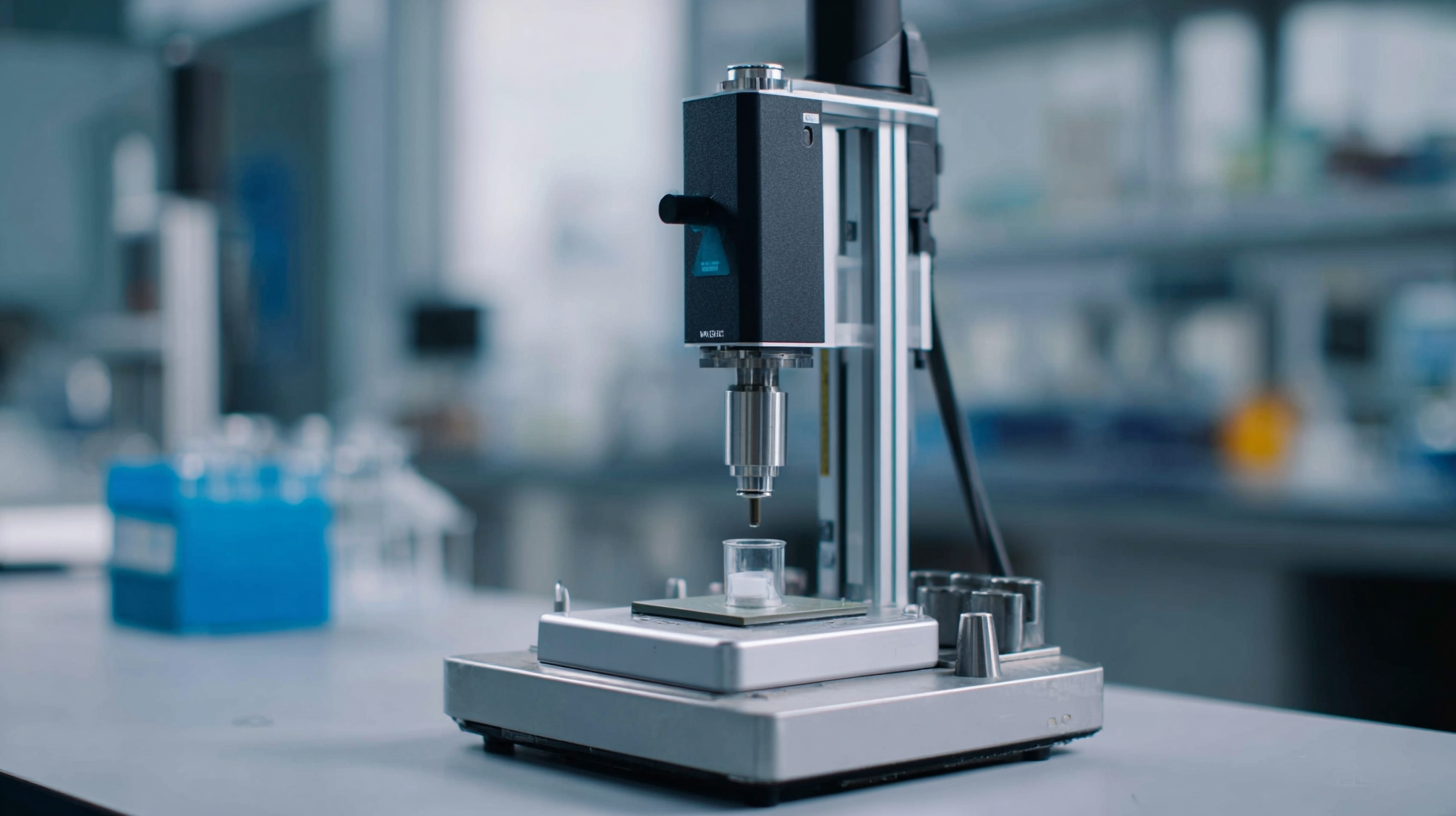

The Nano Debee Homogenizer really is a game-changer when it comes to lab processing. It uses some pretty advanced homogenization tech to get results that are honestly hard to beat. To really get the most out of it, it helps to understand how it works. Basically, it uses high shear forces and intense cavitation to break down samples at the nano level. That combo ensures everything’s mixed really well and particles are uniformly reduced, which makes extraction and emulsification much more efficient.

One thing folks love about the Nano Debee is that it manages to deliver top-notch homogenization without messing up the sample’s integrity. It keeps heating in check by speeding up the process and giving you tight control over shear rates. So, you can process sensitive biological samples without worrying about damaging their structure or properties. Using this kind of technology, researchers can get consistent, reproducible results — super important for quality control and accuracy, especially in fields like pharma, biotech, or food science. Honestly, understanding how it works not only boosts how effectively you can run your tests but also opens up exciting new possibilities for designing experiments and pushing boundaries.

When you're working in a lab and need to do homogenization, picking the right method can really make a difference in your results. CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is known for their state-of-the-art high-pressure homogenizers and microfluidizers, especially the Nano Debee Homogenizer. Compared to older, traditional methods, this thing really shows its power—thanks to a bit of mind-blowing nanotech, it’s more efficient and gives you consistent particle sizes. That means better quality samples overall.

Honestly, looking at the Nano Debee next to standard techniques, it’s clear that it not only helps you process more, but it also reduces the risk of heat damage to those delicate samples. A good tip if you’re thinking about upgrading: do a small pilot study first. Try out both methods with your specific samples—see for yourself how they stack up in terms of speed and quality. Another thing worth considering is how flexible the homogenizer is. While traditional methods often need special setups for different samples, the Nano Debee adapts pretty well across different industries and applications.

And don’t forget—regular maintenance is key. Keep your equipment calibrated and running smoothly. That way, you actually get the most out of what this advanced technology has to offer. If you keep these tips in mind, you’ll be well on your way to getting the best results possible with the Nano Debee Homogenizer and taking your research to the next level.

The Nano DeBee Homogenizer has really started to make waves across various scientific fields, thanks to how efficiently it can process pretty complex samples. For example, in microbiology, folks have found that this little device can break open cells—what we call cell lysis—more than 95% of the time. That’s a big deal because it means you get a much better extraction of what's inside those cells, all while keeping the samples intact. Honestly, that level of efficiency is a game-changer, especially when you're dealing with fragile biomolecules. It’s become almost essential for researchers working on genetics or microbial stuff.

And in pharma, the Nano DeBee pulls double duty. It’s perfect for making drug delivery systems. There’s a study in the International Journal of Pharmaceutics that highlights how it can produce nanoemulsions with droplet sizes around 50 nanometers. That tiny size helps drugs get absorbed better and delivers them more precisely where they need to go. In treatments like cancer, where targeting is everything, that kind of precision can really make a difference. Overall, the variety of ways this tool is being used is totally changing the game for scientists tackling complex problems in these fields.

Getting the best results with the Nano DeBee Homogenizer really comes down to having a game plan that's tailored to your specific lab needs. One thing I always recommend is playing around with the pressure settings depending on what kind of sample you're working with. I read somewhere—in the Journal of Microencapsulation, actually—that cranking up the pressure can cut down particle sizes by as much as 60%. That’s a huge deal for making emulsions more uniform. It’s especially handy when you're dealing with tricky biological samples, where keeping particle size consistent is key, like in drug delivery systems.

Oh, and don’t forget about pre-treatment steps—they can make a world of difference. The Journal of Pharmaceutical Sciences mentions that things like hydration and controlling temperature before homogenizing can really improve dispersion and even cut down the processing time by about 30%. That’s not just saving time but also helping keep sensitive compounds intact, so your results are more reliable and consistent. By combining smart pressure adjustments with pre-treatment techniques, you can really unlock the full potential of the Nano DeBee and get top-notch experimental outcomes.

When you're working with the Nano Debee Homogenizer in your lab, it's pretty important to keep an eye out for a few common issues that can pop up during homogenization. One of the most typical problems? Samples not coming out with the right consistency, which can really mess with your results. To help avoid that, make sure to cool your samples properly before you start homogenizing. It’s a small step, but it helps keep the viscosity just right and makes the process run more smoothly.

Another thing to watch for is wear and tear on the homogenizing chamber. Over time, it can affect how well the machine performs. So, it’s a good idea to check for any signs of damage or wear regularly. Also, don’t forget to give the chamber a good cleaning after each use. Taking good care of your equipment doesn’t just make it last longer — it also helps you get consistent, reliable results every time.

And if you’re finding that your particle size isn’t quite what you expected, try tweaking the pressure settings on the machine. Cranking up the pressure can boost the shearing force, giving you finer emulsions and dispersions. Don’t hesitate to experiment a bit — finding the right pressure for your specific samples can make a big difference in the quality of your results.

: The Nano Debee Homogenizer is a laboratory processing tool that uses advanced homogenization technology. It operates by applying high shear force and intense cavitation to break down samples at the nano-level, ensuring thorough mixing and uniform particle size reduction.

The Nano Debee maintains sample integrity while delivering superior homogenization. It minimizes thermal effects, reduces processing time, and allows for precise control over shear rates, making it ideal for sensitive biological samples.

The Nano Debee is utilized in various fields, including microbiology, pharmaceuticals, biotechnology, and food science, due to its efficiency in processing complex samples.

In microbiology, the Nano Debee can achieve cell lysis rates exceeding 95%, significantly enhancing the extraction of intracellular components while preserving sample integrity, which is vital for genetic studies and microbial analyses.

The Nano Debee is crucial in drug delivery systems, producing nanoemulsions with droplet sizes as small as 50 nanometers, promoting better bioavailability and targeted delivery of therapeutic agents, particularly important in precision medicine.

Adjusting pressure settings based on sample type and incorporating pre-treatment processes can enhance outcomes. Higher pressure can improve particle size reduction, while pre-homogenization steps can reduce homogenization time and preserve sample integrity.

Homogenizing under higher pressure can improve particle size reduction by up to 60%, significantly enhancing the homogeneity of emulsions, which is essential for challenging biological samples.

Pre-treatment processes, such as hydration and temperature regulation, can facilitate better dispersion and reduce homogenization time by 30%, ensuring reliable and reproducible laboratory results.

Yes, the Nano Debee is specially designed to handle sensitive biological samples without compromising their structural or functional properties, making it suitable for various applications in research.

Understanding the mechanisms behind the Nano Debee enhances the efficacy of laboratory techniques and paves the way for innovation in experimental design across different scientific fields.

The Nano Debee Homogenizer is truly a game-changer when it comes to sample prep in the lab. It’s packed with cutting-edge technology that helps get you more consistent, finer results—imagine better mixing and smaller particles, which are super important for all kinds of scientific work. If you take a moment to understand how the Nano Debee system works, you'll find it way easier to get more efficient, reliable homogenization compared to traditional methods. It’s pretty impressive, honestly.

Of course, to really get the most out of your Nano Debee Homogenizer, it’s all about following good practices and knowing how to troubleshoot if something doesn’t go perfectly. CAS PETER (HANGZHOU) NANOTECHNOLOGY CO., LTD is leading the way in this space, offering custom nanotech solutions designed to handle the unique needs of industries that depend on high-pressure and microfluidic homogenization. It’s exciting stuff—and honestly, it makes working with samples a whole lot more streamlined.